Shrinking Machine: Revolutionizing the Processing of Metal Table and Chair Legs

Metal furniture has become increasingly popular over the years, offering durability and a sleek aesthetic that appeals to many interior design enthusiasts. However, the manufacturing process of metal furniture components, such as table and chair legs, has posed several challenges in terms of precision and cost-efficiency. That is until the advent of the revolutionary Shrinking Machine.

The Shrinking Machine, specifically designed for the processing of metal table and chair legs, has transformed the way these components are manufactured. Its innovative technology offers a myriad of benefits, ranging from improved productivity to enhanced product quality. In this article, we will delve into the intricacies of the Shrinking Machine and explore how it is reshaping the metal furniture industry.

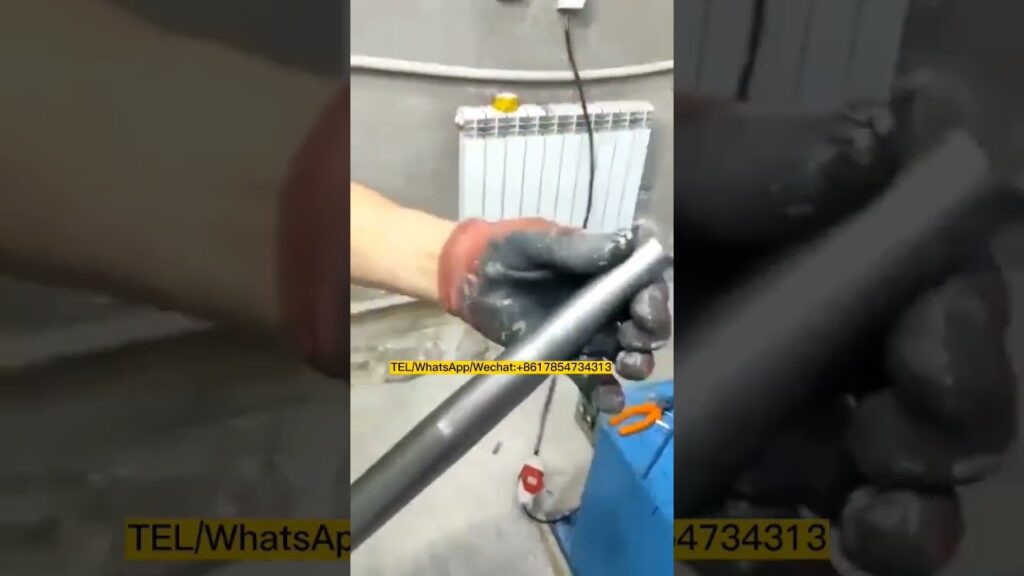

The Shrinking Machine employs a unique taper shrinking process that allows for the precise reduction of the diameter of metal table and chair legs. This process involves the gradual tapering of the legs using advanced heating and cooling techniques. The end result is a seamless, sleek design with consistently accurate dimensions.

One of the key advantages of the Shrinking Machine is its ability to streamline the manufacturing process. Traditional methods of tapering metal legs often required multiple steps and extensive manual labor, leading to increased production time and costs. With the Shrinking Machine, manufacturers can significantly reduce both time and labor involved in producing metal furniture components. This not only translates to higher productivity but also enables manufacturers to meet the growing demand for metal furniture in a timely manner.

Furthermore, the Shrinking Machine ensures unparalleled precision in the tapering process. By employing heating and cooling techniques with meticulous control, manufacturers can achieve precise and consistent results every time. The machine eliminates the risk of human error and ensures that each metal leg is crafted to perfection. This level of precision contributes to the overall quality and longevity of the furniture, instilling confidence in both manufacturers and consumers.

In addition to efficiency and precision, the Shrinking Machine also offers cost-effective benefits. By optimizing the manufacturing process and reducing the reliance on manual labor, manufacturers can significantly cut down on production costs. This cost reduction can then be passed on to consumers, making metal furniture more affordable and accessible to a wider market.

The integration of the Shrinking Machine into the manufacturing process has garnered positive reviews from industry experts and professionals. Its positive impact on productivity, precision, and cost-efficiency has made it a game-changer in the metal furniture industry. Manufacturers who have embraced this innovative technology have witnessed a remarkable transformation in their operations, enabling them to stay ahead in a highly competitive market.

Looking into the future, it is clear that the Shrinking Machine will continue to revolutionize the metal furniture industry. Its potential to further improve productivity and reduce costs is promising, while its meticulous craftsmanship ensures the delivery of high-quality furniture pieces. As the demand for metal furniture continues to grow, manufacturers who choose to invest in the Shrinking Machine will undoubtedly reap the rewards of staying at the forefront of the industry.

In conclusion, the Shrinking Machine has emerged as a game-changer in the processing of metal table and chair legs. Its taper shrinking process, combined with advanced heating and cooling techniques, offers manufacturers unparalleled efficiency, precision, and cost-effectiveness. As the metal furniture industry continues to evolve, the Shrinking Machine will undoubtedly remain a crucial tool in the quest for innovation and excellence.

Shrinking Machine

"Efficient Metal Table and Chair Leg Processing: Discover the Taper Shrinking Machine and Shrinking Machine Techniques"