The Future of Packaging: End of Line Compatible Automatic Stretch Wrapping and AGV Solutions

In today’s fast-paced world, where efficiency and productivity are crucial for businesses to stay competitive, finding innovative and automated solutions has become paramount. This is especially true for the packaging industry, where seamless and reliable operations are required to meet the ever-increasing demands of consumers.

One such groundbreaking solution that has been making waves in the industry is the Automatic Orbital Stretch Wrapper. Developed by Robopac USA and OCME, this cutting-edge technology is revolutionizing end-of-line packaging and stretch wrapping processes. With its advanced features and capabilities, it offers a host of benefits that can greatly streamline operations and increase overall efficiency.

Imagine a future where packaging and wrapping processes are seamlessly integrated into the production line, eliminating the need for manual labor and ensuring consistency in packaging quality. This is precisely what the Automatic Orbital Stretch Wrapper aims to achieve. By automating the stretching and wrapping of palletized loads, it eliminates the risk of human error and significantly reduces the time and effort required for these tasks.

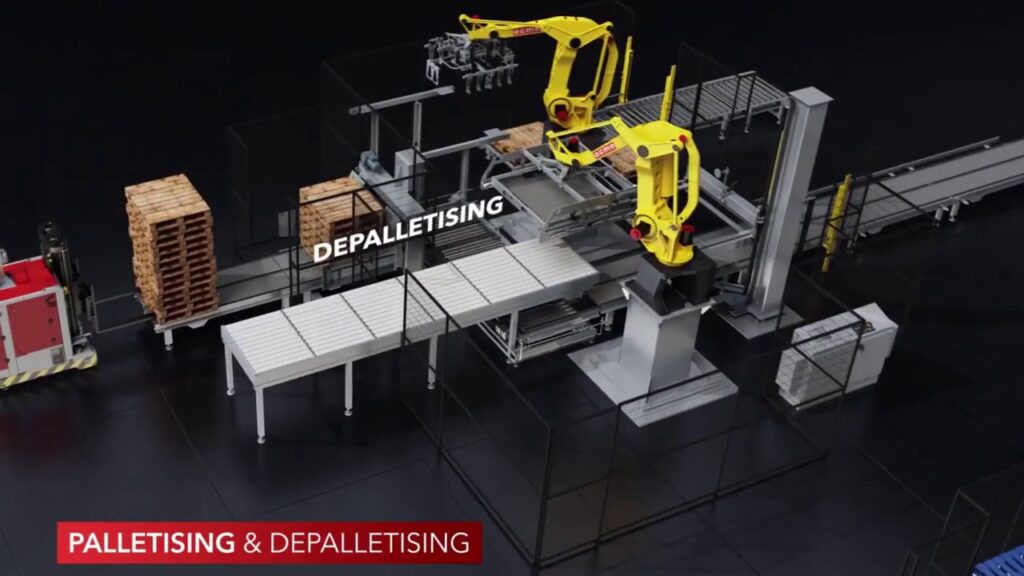

One of the key advantages of this system is its compatibility with end-of-line processes. Traditional stretch wrapping machines often require manual intervention to initiate the wrapping process, leading to bottlenecks and disruptions in the production line. However, the Automatic Orbital Stretch Wrapper seamlessly integrates with existing conveyors and palletizing systems, enabling a smooth, uninterrupted flow of goods throughout the entire packaging process.

Furthermore, this innovative solution is equipped with Laser Guided Vehicles (LGV) and Automated Guided Vehicles (AGV), which further enhance its efficiency and versatility. These vehicles work in tandem with the stretch wrapper, ensuring precise and accurate placement of loads on the wrapping platform. This eliminates the need for manual handling or repositioning of pallets, reducing the risk of accidents and injuries while also optimizing floor space utilization.

The benefits of the Automatic Orbital Stretch Wrapper extend beyond increased efficiency and reduced labor costs. By ensuring consistent and secure wrapping of palletized loads, it enhances product protection and reduces the risk of damage during transportation and storage. This is of utmost importance, particularly for fragile or delicate goods, where any compromise in packaging quality can have severe consequences.

Moreover, this state-of-the-art solution is highly versatile and customizable, catering to the unique needs of different industries. Whether it’s food and beverage, pharmaceuticals, automotive, or any other sector, the Automatic Orbital Stretch Wrapper can be tailored to meet specific packaging requirements. This adaptability ensures that businesses can achieve optimal results without compromising on the quality and safety of their products.

As the technology behind the Automatic Orbital Stretch Wrapper continues to evolve, we can expect even more innovative features to emerge. From advanced sensors and smart algorithms to optimize wrapping patterns, to real-time data analytics that provide valuable insights into packaging performance, the possibilities are endless. This opens up avenues for predictive maintenance, improved resource allocation, and further operational efficiencies.

In conclusion, the Automatic Orbital Stretch Wrapper, in conjunction with end-of-line compatible automatic stretch wrapping and AGV solutions, represents the future of packaging. As businesses strive to streamline their operations and enhance productivity, these cutting-edge technologies offer a game-changing solution. By automating the packaging process, improving efficiency, and ensuring product safety, they empower businesses to stay ahead of the curve in the increasingly competitive market. With the ever-advancing capabilities of these innovative solutions, the future of packaging looks brighter than ever before.

Orbital Stretch Wrapper

“Efficient and Innovative Solutions for Streamlining End of Line Wrapping and Logistic Automation”