**Title: The Innovation of Automatic Wafer Handling Systems Revolutionizes Semiconductor Manufacturing**

Semiconductor manufacturing has once again witnessed a groundbreaking advancement with the invention of the Automatic Handling Machine. This cutting-edge technology aims to streamline and optimize the intricate processes involved in producing semiconductor wafers. In this article, we will explore the remarkable features of this groundbreaking innovation and its potential to transform the industry.

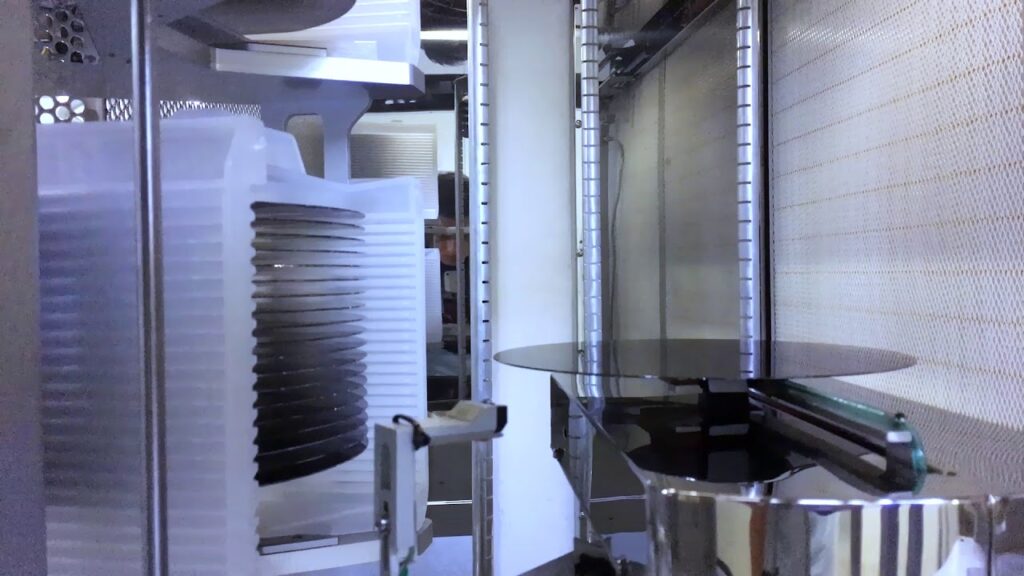

The Automatic Handling Machine represents a significant leap forward in semiconductor manufacturing, particularly in improving the efficiency of the Vertical Furnace process. This state-of-the-art system revolutionizes the transportation and handling of wafers, ensuring seamless integration with existing production lines and simplifying the complex workflow.

One of the most striking features of the Automatic Handling Machine is its high precision and accuracy in wafer manipulation. Equipped with advanced robotic arms and intelligent sensors, this system ensures the secure handling of delicate wafers without the risk of damage or contamination. By eliminating human errors, the Automatic Handling Machine enhances product quality and dramatically reduces wastage, maximizing the overall yield.

The integration of automation and robotics in the semiconductor industry has been an ongoing trajectory for some time, but the Automatic Handling Machine has taken it to new heights. Its exceptional speed and efficiency have immensely improved the production cycle, leading to shorter lead times and increased output capacity. Manufacturers can now meet growing demands while maintaining excellent quality standards.

Furthermore, the Automatic Handling Machine’s sophisticated software allows for seamless communication and coordination with other machines within the production line. This synchronicity ensures a smooth workflow, minimizes downtime, and optimizes overall operational efficiency. The system can be easily programmed to perform various tasks, such as unloading wafers from cassettes, aligning them for processing, and transferring them to subsequent phases without human intervention.

When it comes to the safety of both the equipment and operators, the Automatic Handling Machine goes above and beyond. Its built-in safety features prioritize accident prevention, ensuring a secure working environment. With advanced sensors and emergency stop mechanisms, the system promptly reacts to any potentially hazardous situations, safeguarding both the valuable equipment and the personnel.

The significance of the Automatic Handling Machine is not limited to its impact on the production line alone. This groundbreaking technology has far-reaching implications for the broader semiconductor industry. Its automation capabilities free up human resources, allowing skilled professionals to focus on more complex tasks, research, and innovation. This new paradigm enhances productivity, fosters a culture of continuous improvement, and opens up new avenues for growth and development.

In the near future, we can expect the Automatic Handling Machine to evolve even further. As the semiconductor industry continues to advance, this technology will adapt and integrate additional functionalities, pushing the limitations of automation and precision. From optimizing logistics to enabling real-time analytics, the potential applications of the Automatic Handling Machine are boundless.

In conclusion, the introduction of the Automatic Handling Machine has revolutionized the semiconductor manufacturing industry, specifically in the context of wafer handling and transportation. This state-of-the-art system has brought about unparalleled precision, efficiency, and automation, eliminating unnecessary human errors and optimizing the production workflow. With its remarkable features and potential for further development, the Automatic Handling Machine paves the way for a new era of semiconductor manufacturing, where innovation and productivity go hand in hand.

Handling Machine

“Efficient and Reliable Automatic Wafer Handling System and Handling Machine for Vertical Furnace: A Practical Solution”