Handling heavy drums or barrels can be a challenging task, especially when it comes to lifting and turning them. Fortunately, there are ergonomic solutions available in the market that can simplify this process. In this article, we will explore one such solution – the electric drum lifter and filter. This innovative piece of handling equipment is designed to make drum handling a breeze, ensuring efficiency and safety in the workplace.

The electric drum lifter and filter is a versatile and user-friendly solution that can be used in various industries such as manufacturing, chemical, pharmaceutical, and more. With this equipment, the process of lifting and turning heavy drums becomes effortless, saving time and minimizing the risk of injuries. Let’s delve deeper into the features and benefits of this powerful handling equipment.

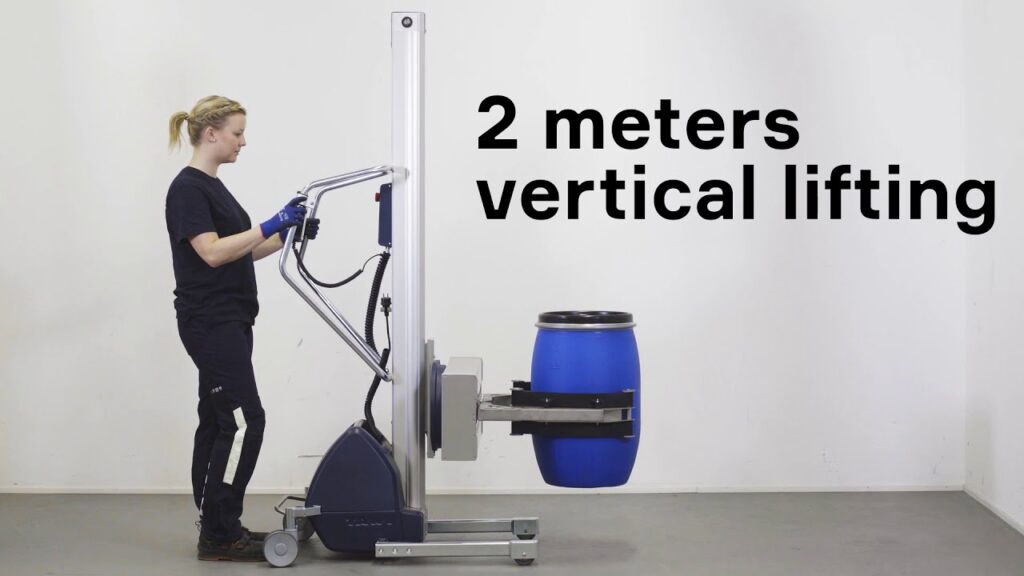

The ergonomic design of the electric drum lifter and filter is a standout feature. It is equipped with adjustable arms and jaws that can securely grip drums of different sizes and shapes. This flexibility allows operators to handle a variety of drums without the need for additional tools or equipment. The lifting mechanism is powered by electricity, making it effortless to lift and turn drums, even those weighing up to several hundred pounds.

Additionally, the electric drum lifter and filter is designed to promote proper posture and reduce strain on the operator’s body. The equipment is crafted with ergonomics in mind, ensuring that lifting and turning drums can be done with ease. This not only enhances productivity but also reduces the risk of musculoskeletal disorders and work-related injuries.

Safety is a significant concern when it comes to handling heavy drums. The electric drum lifter and filter addresses this concern by incorporating advanced safety features. It is equipped with a robust locking mechanism that securely holds the drum in place during lifting and turning. This prevents accidental drops or spills, minimizing the risk of injuries and damage to property.

Furthermore, the electric drum lifter and filter is designed to be user-friendly and intuitive. It incorporates easy-to-use controls, allowing operators to operate the equipment with minimal training or experience. This makes it a suitable solution for businesses looking to improve efficiency and minimize downtime.

Additionally, the electric drum lifter and filter is equipped with intelligent sensors and filters that ensure optimal performance and longevity. The filters prevent contaminants from entering the mechanism, prolonging the lifespan of the equipment. This reduces maintenance costs and enhances the overall reliability of the solution.

Now, let’s delve into a case study to understand how the electric drum lifter and filter can transform drum handling operations in a real-world scenario.

Case Study: A Chemical Manufacturing Company

ABC Chemicals, a leading manufacturer of specialty chemicals, was struggling with the manual handling of drums in their production facility. The process of lifting and turning heavy drums was not only time-consuming but also posed a significant risk to their employees’ safety.

To address these challenges, ABC Chemicals decided to invest in the electric drum lifter and filter. The results were remarkable. The ergonomic design of the equipment allowed their operators to handle drums effortlessly, increasing productivity and reducing the risk of injuries.

The adjustable arms and jaws of the equipment made it easy to lift and turn drums of varying sizes. Furthermore, the intelligent sensors and filters ensured optimal performance, minimizing downtime and maintenance costs.

The electric drum lifter and filter not only simplified the drum handling process but also improved the overall efficiency of ABC Chemicals’ production facility. With this state-of-the-art handling equipment, they were able to streamline their operations and achieve higher productivity levels.

In conclusion, the electric drum lifter and filter is a game-changer in the world of drum handling equipment. Its ergonomic design, user-friendly controls, and advanced safety features make it an ideal solution for industries that need to handle heavy drums or barrels. Whether you are in the manufacturing, chemical, pharmaceutical, or any other industry, this equipment can revolutionize your drum handling operations, ensuring efficiency, safety, and productivity.

Investing in the electric drum lifter and filter is a wise decision that will have a positive impact on your business. Say goodbye to manual drum handling struggles and embrace this ergonomic solution for a more efficient and safer workplace.

Handling Machine

“Efficient Drum Lifting: Discover Ergonomic Solutions and Optimal Handling Equipment for Safer Operations”