Bag Packaging Machine: Revolutionizing Packaging Efficiency

Packaging plays a crucial role in various industries, ensuring the safe transportation and preservation of products. Efficient packaging not only protects goods but also helps maintain their quality and appearance. In the modern era, manufacturers are continually seeking innovative solutions to streamline their packaging processes and improve productivity. This is where the Bag Packaging Machine comes into play – a technological marvel that has revolutionized the packaging industry.

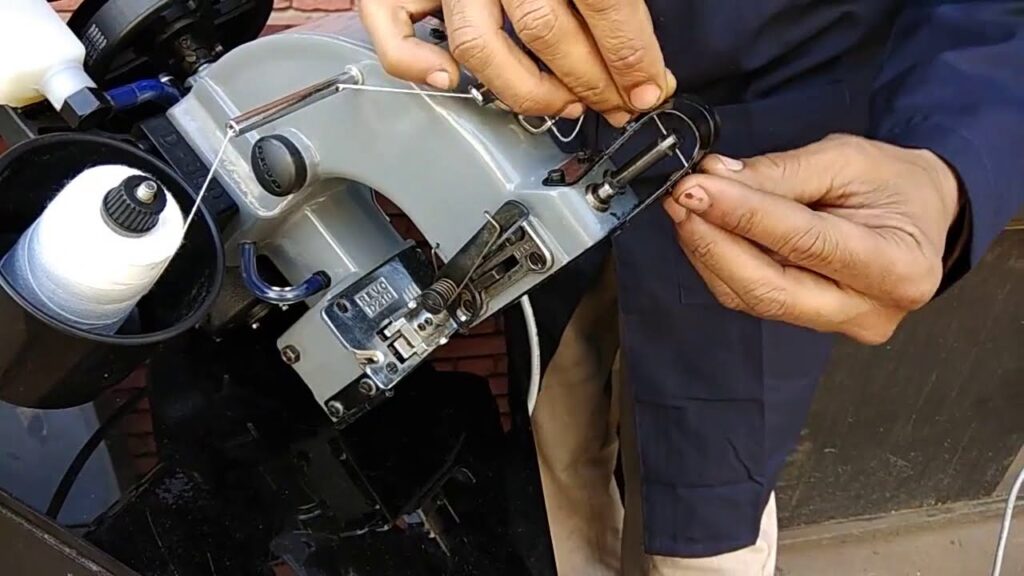

The Bag Packaging Machine, also known as the Revo Bag Closer Machine Model DA, is an exceptional piece of machinery that provides a seamless solution for packaging requirements. This cutting-edge equipment offers several features and benefits that have proven to be a game-changer for companies across different sectors.

Designed by a team of skilled engineers, the Bag Packaging Machine boasts an unmatched level of precision and efficiency. It is equipped with state-of-the-art technology, enabling it to achieve high speeds and impeccable accuracy. With this machine, companies can experience a significant increase in their packaging output, saving both time and labor costs.

One key feature that sets the Bag Packaging Machine apart is its threading and operating system. The machine’s threading mechanism ensures a smooth and hassle-free packaging process, minimizing any errors or disruptions. This automated system eliminates the need for manual intervention, reducing the chances of human error and enhancing overall productivity.

Moreover, the operating system of the Bag Packaging Machine is incredibly user-friendly, making it accessible to operators of various skill levels. Its intuitive interface allows for convenient control and monitoring, enabling operators to adjust settings, troubleshoot issues, and optimize the packaging process effortlessly.

The Bag Packaging Machine is also known for its versatility, as it can handle a wide range of bag sizes and materials. Whether it’s packaging food products, pharmaceuticals, pet food, or even heavy-duty industrial materials, this machine can adapt to various requirements. This flexibility makes it an ideal choice for manufacturers looking to streamline their packaging operations for diverse product lines.

Furthermore, the Bag Packaging Machine’s compact design and robust construction optimize floor space utilization and ensure durability. Its robust build can withstand the rigors of continuous operation, promising longevity and reliability. Additionally, the machine’s low maintenance requirements save costs and minimize downtime, allowing for uninterrupted packaging processes.

To understand the impact of the Bag Packaging Machine better, let’s delve into a case study of a manufacturing company that integrates this revolutionary technology into their operations.

ABC Manufacturing, a leading player in the food packaging industry, was facing significant challenges in meeting their packaging targets due to manual labor limitations and errors. Seeking a solution, they decided to invest in the Bag Packaging Machine. The integration of this innovative equipment resulted in a dramatic increase in their packaging efficiency, enabling them to achieve their production goals consistently.

The seamless threading and operating system of the Bag Packaging Machine significantly reduced packaging errors, ensuring each product was packaged accurately and securely. This improved product quality, minimized customer complaints, and increased customer satisfaction. With the ability to handle various bag sizes and materials, ABC Manufacturing could now cater to a broader range of customers, opening doors to new market opportunities.

The Bag Packaging Machine’s exceptional performance also led to a reduction in labor costs for ABC Manufacturing. With the automation of the packaging process, the need for manual labor decreased significantly, allowing the company to reallocate resources to other areas of production. This cost-saving measure translated into increased profitability and a positive impact on the company’s bottom line.

In conclusion, the Bag Packaging Machine represents a breakthrough in the packaging industry, revolutionizing efficiency and productivity. Its advanced features, such as the threading and operating system, ensure seamless operation and reduce errors, leading to improved product quality and customer satisfaction. The machine’s versatility, durability, and low maintenance requirements make it an invaluable asset to manufacturers across various sectors.

As technology continues to advance, the Bag Packaging Machine is poised to evolve further, integrating cutting-edge features to meet the ever-changing demands of the packaging industry. With its transformative impact and potential for future innovation, this machine is undoubtedly a game-changer in the world of packaging.

Bagging Machine

“Efficient Bag Closure and Packaging: Mastering the DA Threading & Operating Process with the Revo Bag Closer and Packaging Machine”