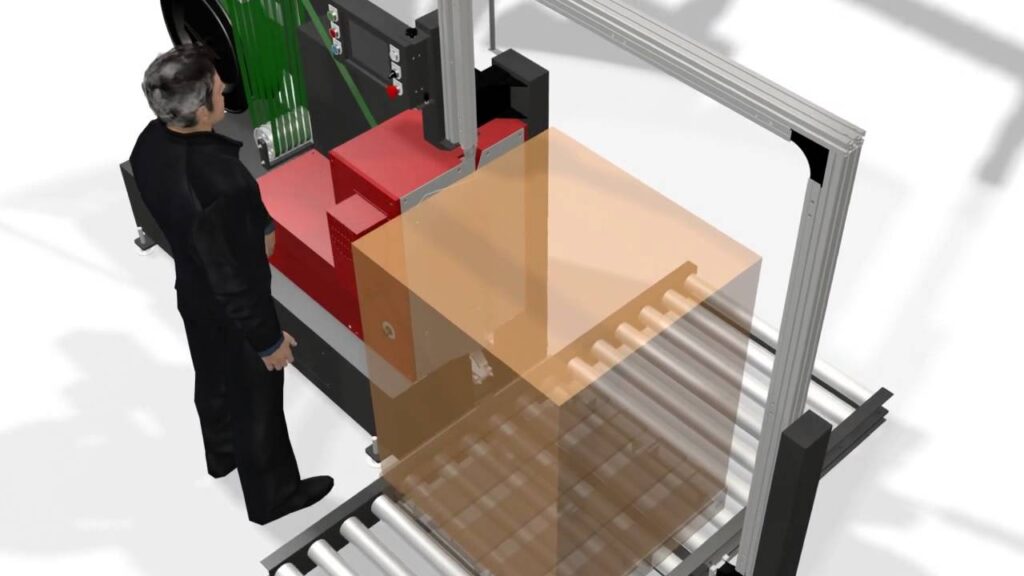

Strapping machines play a vital role in streamlining the packaging process in numerous industries, ensuring that products are securely bundled together for transportation and storage. Among the various options available in the market, the Industrial Strapping Machine stands out as a versatile and efficient choice. With adjustable height settings for both machine and conveyor, this machine offers great flexibility in accommodating different packaging needs.

When it comes to industrial packaging, efficiency and reliability are key factors to consider. The Industrial Strapping Machine, specifically the U-series Pallet Strapping Machine – UYAOLF, ticks both these boxes, making it a popular choice among manufacturers and logistics companies. The ability to adjust the height of the machine and conveyor adds another layer of convenience, allowing for seamless integration into existing production lines.

One of the major advantages of the Industrial Strapping Machine is its adaptability to different packaging requirements. Whether you are dealing with small packages or large pallets, the adjustable height feature ensures that the strapping machine can be set up to match the specific dimensions of the products being packaged. This eliminates the need for manual adjustments or additional equipment, saving valuable time and resources.

Imagine a scenario where a company needs to package a variety of products, ranging from small boxes to bulky crates. With a fixed-height strapping machine, they would constantly have to pause their operations, make manual adjustments, and ensure that the machine is set up correctly for each packaging task. This not only slows down the packaging process but also increases the chances of errors and inconsistencies.

However, with the Industrial Strapping Machine’s adjustable height settings, these issues become a thing of the past. The machine can be easily configured to match the height of the product being packaged, reducing the setup time and ensuring consistent and precise strapping each time. This enhances productivity and minimizes the chances of errors, resulting in cost savings and improved customer satisfaction.

Moreover, the adjustable height feature of the Industrial Strapping Machine also extends to the conveyor. The conveyor can be raised or lowered to align perfectly with the strapping machine, facilitating a smooth transition of products through the packaging process. This eliminates any unnecessary transfer or handling of the products, reducing the risk of damage or accidents.

Beyond the benefits of adjustable height, the Industrial Strapping Machine is also known for its user-friendly interface, durability, and reliability. Its robust construction ensures that it can withstand the rigors of industrial packaging operations, providing a long service life with minimal maintenance requirements. Additionally, the machine can be easily integrated with other packaging equipment, such as sealers and stretch wrappers, creating a seamless and efficient packaging line.

In conclusion, the Industrial Strapping Machine, with its adjustable height settings for both machine and conveyor, offers a versatile solution for various packaging needs. Whether dealing with small packages or large pallets, this machine ensures an efficient and reliable packaging process. By eliminating the need for manual adjustments and facilitating seamless integration into existing production lines, it enhances productivity, reduces errors, and ultimately leads to cost savings. If you are in the market for a strapping machine, the Industrial Strapping Machine should definitely be on your radar. Its flexibility, durability, and user-friendly interface make it a top choice in the industry.

For more information about the Industrial Strapping Machine, you can visit [link removed].

Strapping Machines

“Efficient Pallet Strapping Machines for Industrial Applications – Enhance Packaging Process with U-Series and Advanced Strapping Machines”