Industrial Robot Price: Revolutionizing the Manufacturing Industry

Industrial automation has been a game-changer in the manufacturing industry, streamlining processes, reducing costs, and improving efficiency. One crucial element of this automation revolution is the adoption of industrial robots. These state-of-the-art machines have revolutionized several manufacturing processes, from arc welding to loading and unloading, stamping, palletizing, and beyond. In this article, we will explore the incredible potential of these robots and their impact on the industry.

The industrial robot market has witnessed tremendous growth in recent years, and it is poised to continue its upward trajectory. As a factory dedicated to producing robots for various applications, we understand the importance of delivering top-notch products that meet the industry’s demands. Our expertise lies in creating highly efficient robots for arc welding, loading and unloading, stamping, palletizing, and numerous other manufacturing tasks.

One of the critical factors that companies consider when integrating industrial robots into their production lines is the price. While the benefits of these robots are undeniable, it is essential to strike a balance between performance and cost-effectiveness. That is precisely what we offer with our welding robots, which combine superior performance with a reasonable price point.

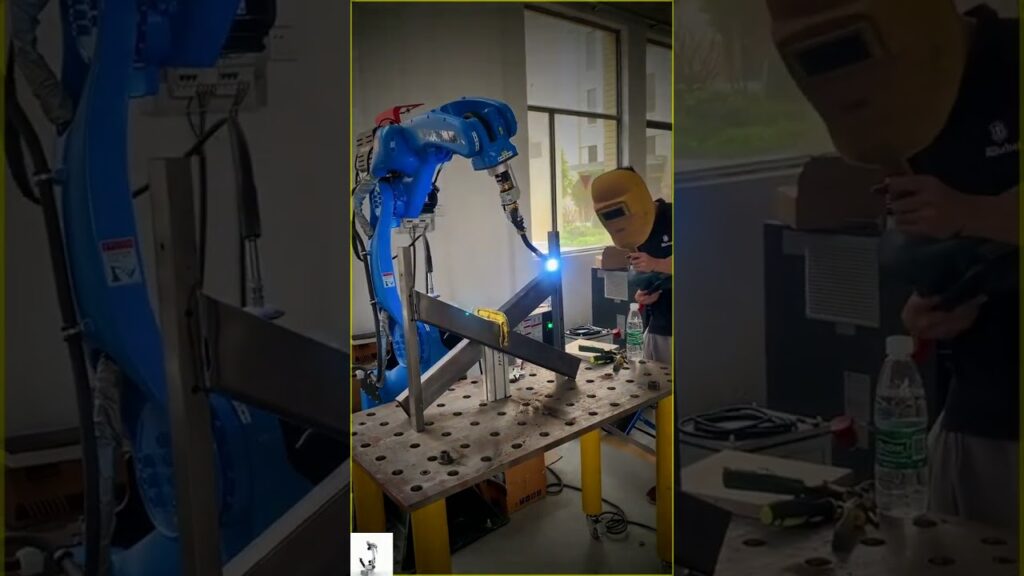

When it comes to industrial robots, welding applications warrant special attention. Welding is a crucial process in various industries, including automotive, aerospace, and construction. Traditionally, welding tasks relied heavily on manual labor, which resulted in inconsistencies, quality issues, and safety concerns. However, the introduction of welding robots revolutionized this process.

With our welding robots, manufacturers can rest assured knowing that they are investing in cutting-edge technology. These robots have been designed to perform complex welding tasks with exceptional precision and speed, resulting in consistently high-quality welds. The robotic arms’ advanced sensors and software algorithms enable them to adjust to variations in workpieces, ensuring optimal weld seam quality.

Moreover, our welding robots offer an impressive cost advantage compared to traditional manual welding methods. By automating the welding process, companies eliminate the need for a large workforce, which significantly reduces labor costs. Additionally, the higher efficiency and productivity of these robots translate into faster production cycles, leading to increased output and a significant boost in profitability.

Another critical aspect of industrial robots is their versatility. Our robots can handle various tasks beyond welding, such as loading and unloading, stamping, and palletizing. This versatility adds further value to manufacturers, as they can use the same robot for multiple applications, maximizing the return on investment.

In terms of pricing, our industrial robots offer a competitive edge without compromising quality. We understand the importance of price when it comes to selecting automation solutions, and we strive to provide our customers with the best value for their money. By leveraging our extensive industry experience and cutting-edge technology, we have streamlined our production processes to deliver high-performance robots at a lower price point.

The impact of industrial robots on the manufacturing industry goes far beyond cost savings. These robots offer unparalleled precision, efficiency, and safety, thereby positioning companies for success in a highly competitive landscape. By investing in industrial robots, manufacturers can enhance their production capabilities, improve product quality, and increase their overall productivity.

As the manufacturing industry continues to evolve, it is crucial for businesses to embrace automation and leverage the power of industrial robots. With our range of robots designed for arc welding, loading and unloading, stamping, palletizing, and more, we are committed to empowering manufacturers with the tools they need to thrive.

In conclusion, industrial robots have revolutionized manufacturing processes across various industries. They have become an indispensable part of the production line, enabling companies to achieve higher performance, lower costs, and improved safety. Our factory’s dedication to creating top-notch robots has resulted in welding robots that offer superior performance at a competitive price point. By investing in industrial robots, manufacturers can embark on a path of innovation and success that will shape the future of the manufacturing industry.

Industrial Robot

“Unveiling the Welding Robot’s Remarkable Performance at an Unbeatable Price!”