Industrial Robots in Manufacturing: Revolutionizing the Future of Production

The field of manufacturing has rapidly advanced in recent years, thanks to the integration of intelligent digital technologies. One notable institute leading the way in this revolution is the Intelligent Digital Manufacturing Laboratory (IDML) at the University of Manitoba in Canada. Through their groundbreaking research and development efforts, IDML is shaping the future of manufacturing with a focus on Industrial Robots in Manufacturing.

Industrial robots have long been associated with streamlining and automating production processes. However, they have traditionally been limited in their capabilities, often requiring external sensors and extensive programming to operate effectively. The IDML’s research aims to overcome these limitations and take industrial robot technology to new heights.

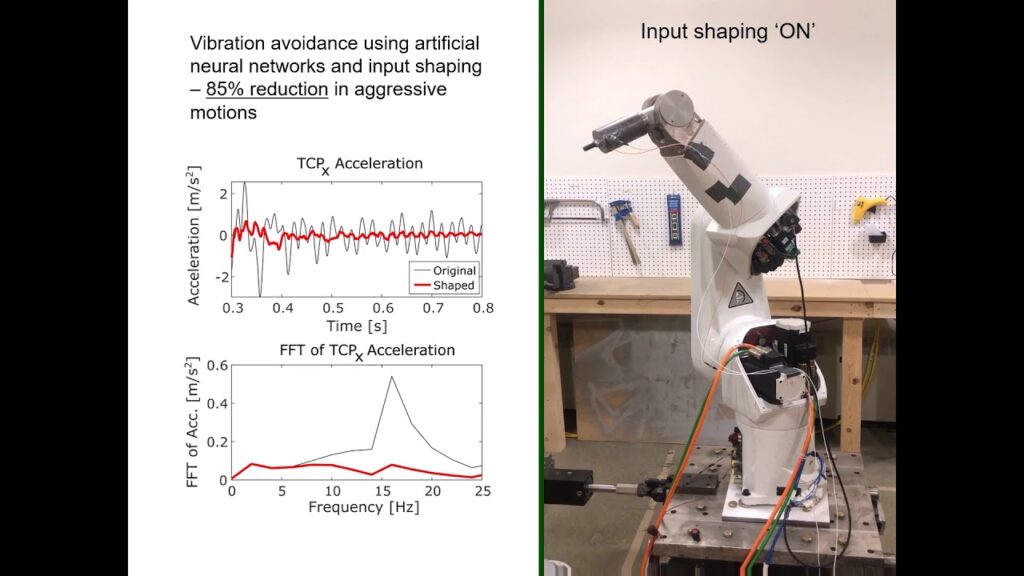

Vibration control is a critical aspect of high-speed industrial robots. The IDML has made significant advancements in this area, developing innovative solutions that minimize vibrations during robot movements. By effectively controlling vibrations, they can improve the precision and overall performance of robots in manufacturing environments.

One of the key objectives of the IDML is to address the challenges associated with the integration of robotic systems into manufacturing industries. Through their research, they aim to enhance the adaptability and flexibility of robots to meet the diverse needs of different production processes. This will enable manufacturers to seamlessly integrate robots into their operations, resulting in increased efficiency and productivity.

To achieve these goals, the IDML collaborates with various industry partners to develop cutting-edge robotic technologies. By working closely with companies and understanding their specific requirements, the lab can tailor their research to address real-world manufacturing challenges. This partnership approach ensures that the developed solutions are not just theoretical concepts but practical innovations that can be implemented on the production floor.

The IDML’s research also focuses on improving the intelligence of industrial robots. They are developing advanced algorithms and machine learning techniques that enable robots to perceive and respond to their environment in real-time. This enhanced intelligence allows robots to adapt to changing conditions and make autonomous decisions, further enhancing their usefulness in dynamic manufacturing environments.

Furthermore, the IDML recognizes the importance of human-robot collaboration in the future of manufacturing. Their research includes developing safe and efficient interaction methods between humans and robots, allowing them to work side by side seamlessly. This collaborative approach not only enhances productivity but also opens up new possibilities for tasks that require human dexterity and decision-making.

The impact of the IDML’s research extends beyond the laboratory walls. Through their collaboration with industry partners, they aim to revolutionize manufacturing processes across various sectors, including automotive, electronics, and healthcare. The adoption of their innovative robotic technologies can lead to faster production cycles, higher product quality, and improved worker safety.

Looking ahead, the IDML’s contributions are expected to shape the future of manufacturing. With their focus on industrial robots, they are paving the way for a new era of production, where intelligent machines work hand in hand with humans. The potential benefits of their research are immense, offering increased productivity, cost savings, and a more sustainable manufacturing industry.

The IDML’s work at the University of Manitoba deserves recognition not only for its technical achievements but also for its potential to change the way we manufacture goods. By bridging the gap between academia and industry, they are facilitating the adoption of advanced manufacturing technologies and ensuring that Canada remains at the forefront of global manufacturing innovation.

In conclusion, the Intelligent Digital Manufacturing Laboratory (IDML) at the University of Manitoba is pushing the boundaries of manufacturing technology through its research on Industrial Robots in Manufacturing. With a focus on vibration control, enhanced intelligence, and human-robot collaboration, the IDML’s innovations have the potential to revolutionize manufacturing processes and unlock new possibilities for industries worldwide. As we look toward the future, it is clear that the integration of industrial robots in manufacturing will play a crucial role in creating efficient, sustainable, and advanced production systems.

Industrial Robot

“Enhancing Precision in Industrial Robots: Optimal Vibration Control for High-Speed Manufacturing”