The advent of technology has revolutionized various industries, and the furniture manufacturing sector is no exception. As companies strive to enhance efficiency and streamline their production processes, the introduction of innovative machinery has become inevitable. One such remarkable invention is the Steel Pipe Shrinking Machine, which has transformed the way desk and chair legs are manufactured.

The development of the Steel Pipe Shrinking Machine can be attributed to the tireless effort of engineers and technicians who understand the nuances of metal pipe and solid bar cutting and chamfering. With this state-of-the-art machine, the process of shaping and resizing steel pipes for the production of desk and chair legs has become faster, more accurate, and highly efficient.

This article aims to provide an in-depth analysis of the Steel Pipe Shrinking Machine and its implications for the furniture manufacturing industry.

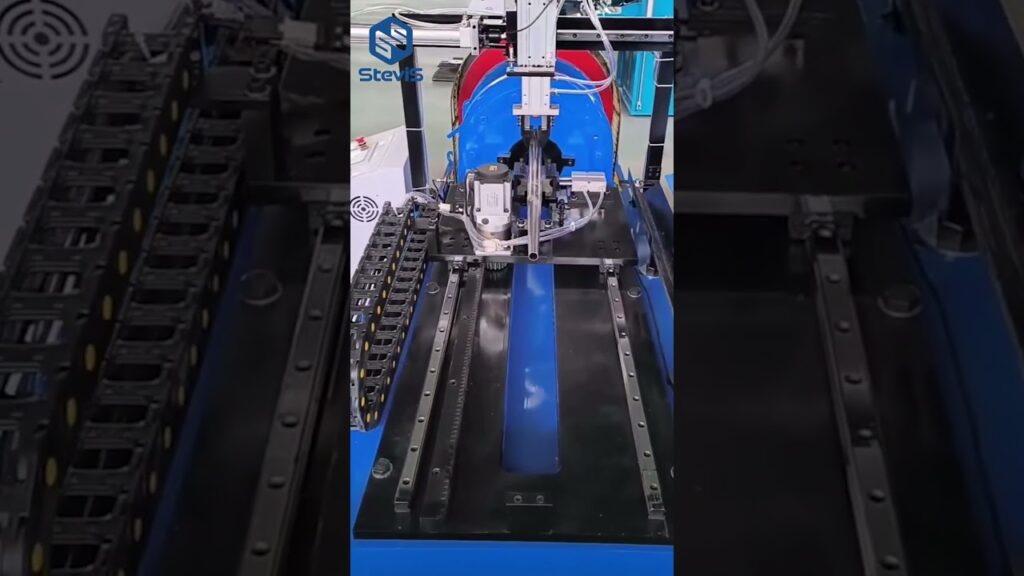

[SteviS cutting machine] Steel Pipe Shrinking Machine is a testament to the relentless pursuit of excellence. Equipped with cutting-edge technology and advanced features, this machine has revolutionized the production process of desk and chair legs. Its cutting and chamfering capabilities are second to none, allowing manufacturers to achieve unprecedented precision and accuracy.

The Steel Pipe Shrinking Machine adopts an inductive structure, which ensures seamless and uninterrupted operation. This innovative design eliminates the need for manual intervention and significantly reduces the margin for error. Manufacturers can rely on this machine to consistently produce high-quality furniture legs with precise dimensions, resulting in a uniform and aesthetically pleasing end product.

The progressive structure of the Steel Pipe Shrinking Machine further enhances its efficiency. By taking into account the cause and effect relationship between each process, this machine optimizes the production sequence, resulting in a streamlined workflow. Manufacturers can witness a remarkable increase in productivity and a reduction in overall production time, allowing them to meet tight deadlines without compromising on quality.

Furthermore, the Steel Pipe Shrinking Machine adheres to a comparative structure. By comparing different sizes and shapes, it automatically adjusts its settings to accommodate various pipe dimensions, ensuring versatility in production. This feature eliminates the need for manual adjustments, saving time, and simplifying the manufacturing process.

The Steel Pipe Shrinking Machine not only offers unparalleled functionality but also ensures a safe working environment. Equipped with advanced safety mechanisms and sensors, it minimizes the risk of accidents and injuries. Manufacturers can trust in the reliability and efficiency of this machine, knowing that it upholds the utmost standards of safety.

In conclusion, the Steel Pipe Shrinking Machine marks a significant advancement in the furniture manufacturing industry. Its cutting-edge technology and innovative features have transformed the way desk and chair legs are produced. With its inductive and comparative structures, this machine enables manufacturers to achieve unparalleled precision, productivity, and efficiency. By embracing this remarkable invention, furniture manufacturers can enhance their production processes, meet market demands, and deliver superior quality products.

The future of furniture manufacturing is here, and it’s embodied in the Steel Pipe Shrinking Machine. As technology continues to evolve and improve, we can expect further advancements in the industry, driving innovation and revolutionizing the way we create furniture. The Steel Pipe Shrinking Machine is just the beginning of a new era, and its implications are bound to shape the future of furniture manufacturing.

Shrinking Machine

“Efficient Steel Pipe Shrinking Machine for Desk and Chair Legs Manufacturing: Boost Production with SteviS Cutting Machine”