Shrink Sleeve Labels: Enhancing Product Packaging with Shrink Wrap Machines

In today's competitive market, product packaging plays a crucial role in attracting customers and standing out from the competition. One of the popular packaging solutions that has gained traction in recent times is the use of shrink sleeve labels. These labels not only provide a visually appealing look to products but also offer several practical benefits. In this article, we will explore the world of shrink sleeve labels and how they can be efficiently applied using a shrink wrap machine.

Shrink sleeve labels are supplied from a roll in the form of a continuous film. These labels are made from materials like PVC or PETG and are designed to perfectly fit the shape of the container they are applied on. The film has a slight elasticity due to which it can shrink tightly around the container when heat is applied. This tight shrinkage ensures that the label conforms seamlessly to the shape and contours of the product, giving it a high-quality appearance.

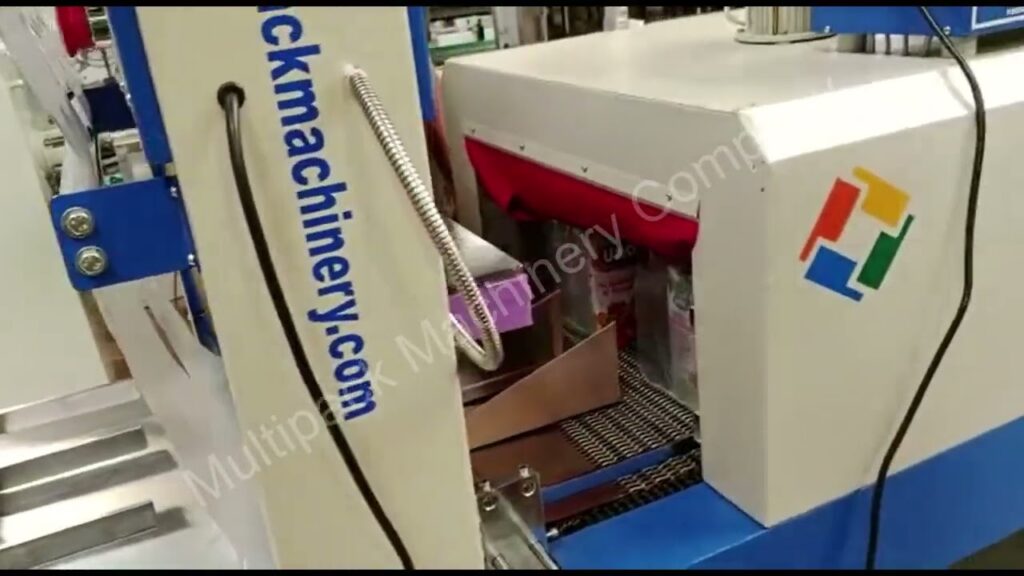

Now, you might wonder how these shrink sleeve labels are applied to products. This is where a shrink wrap machine comes into play. A shrink wrap machine is a versatile packaging equipment that is designed specifically for the application of shrink sleeve labels. It uses a combination of heat and controlled air flow to shrink the film tightly around the product, providing a secure and visually appealing packaging.

There are different types of shrink wrap machines available in the market, depending on the packaging requirements. For instance, bottle, jar, and box shrink wrap machines are specifically designed to accommodate different types of containers. These machines come with adjustable settings to ensure the proper application of shrink sleeve labels regardless of the shape or size of the product.

The process of applying shrink sleeve labels using a shrink wrap machine is simple yet effective. Once the product is placed inside the machine, it passes through a heating tunnel where hot air is blown onto the film. This heat activates the shrink properties of the film, causing it to conform tightly to the product shape. As the product moves through the tunnel, the label shrinks, forming a secure seal and ensuring a professional finish.

The advantages of utilizing shrink sleeve labels and shrink wrap machines are manifold. Firstly, these labels offer 360-degree coverage, providing ample space to display attractive graphics, branding, and essential product information. This 360-degree coverage sets the product apart from others on the shelf, captivating the attention of potential customers.

Secondly, shrink sleeve labels offer excellent durability and tamper-evidence. The tight seal created by the shrink wrap machine ensures that the label remains intact throughout the product's journey, safeguarding it from moisture, sunlight, and other environmental factors. Additionally, the tamper-evident feature of shrink sleeve labels provides a level of trust and security to consumers.

Furthermore, shrink sleeve labels are suitable for a wide range of industries and products. From food and beverages to cosmetics and household items, shrink sleeve labels can be applied to various packaging types. This versatility makes shrink wrap machines an essential investment for businesses of all sizes.

In conclusion, shrink sleeve labels have revolutionized product packaging by offering an attractive, durable, and practical solution. With the help of shrink wrap machines, these labels can be efficiently and seamlessly applied to different types of products. The use of shrink sleeve labels not only enhances the visual appeal of the product but also provides an added layer of protection. Whether you are a manufacturer looking to enhance your product packaging or a consumer wanting a visually appealing product, shrink wrap machines and shrink sleeve labels are the perfect combination to achieve your packaging goals.

Shrinking Machine

"Efficient Shrink Wrap Machine for Bottles, Jars, and Boxes – Streamline Your Packaging Process with Shrink Wrapping Bundling Technology"