Industrial Robotic Arm: Revolutionizing Manufacturing Processes

The advancement of technology has transformed numerous industries, and the manufacturing sector is no exception. With the rapid development of automation, industrial robots have become the backbone of modern manufacturing processes. Among the many innovative creations, the Industrial Robotic Arm stands out as one of the most revolutionary inventions in the field.

*(Introduction)*

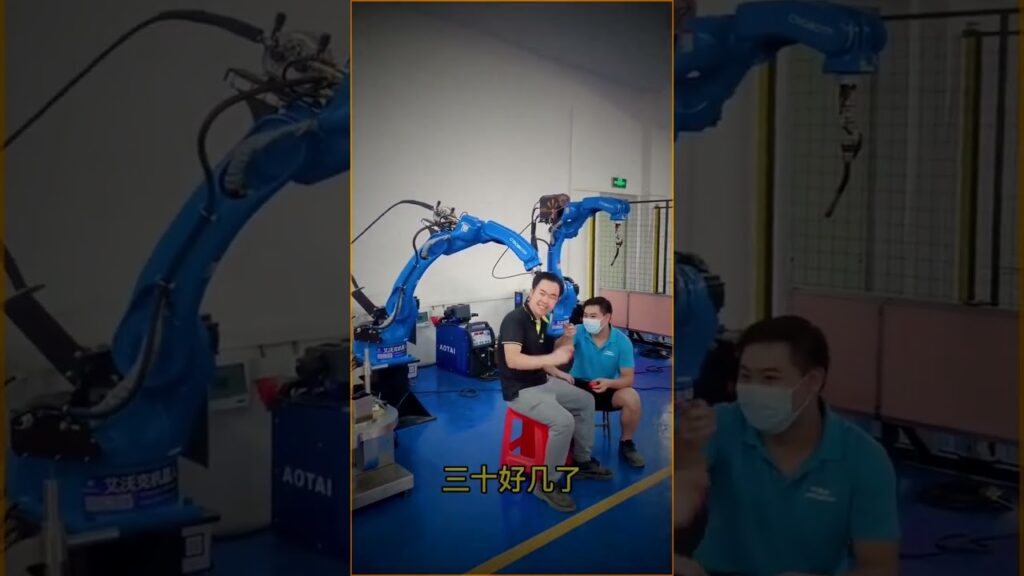

The Industrial Robotic Arm, with its exceptional capabilities and versatility, has become an indispensable tool in factories worldwide. Its applications range from arc welding and stamping for press machines to loading and unloading heavy materials. This powerful machine, also known as an industrial robot palletizer robotic arm manipulator automatic welding robot 6 axis, has significantly enhanced productivity and efficiency in manufacturing industries.

*(Explanatory Style)*

The Industrial Robotic Arm operates with precision and accuracy, executing tasks with dexterity impossible for humans to replicate. Its six axes of movement allow it to perform intricate maneuvers effortlessly. Equipped with advanced sensors and software, this robotic arm can adapt to various environments while ensuring employee safety.

This remarkable technology is transforming the welding industry. With arc welding being a physically demanding and labor-intensive process, the Industrial Robotic Arm has provided a much-needed solution. Its ability to weld with extreme precision and consistency has elevated the quality of welds, resulting in stronger and more reliable products. Furthermore, the robotic arm’s efficiency effectively reduces production time and costs.

*(Narrative Style)*

Let’s take a closer look at a real-life case study to demonstrate the benefits of the Industrial Robotic Arm. A manufacturing company, facing challenges in their welding operation, decided to implement this technology. They predominantly used manual welding, which was time-consuming and had quality control issues. Consequently, the company experienced delays in meeting customer demands and suffered from increased costs due to rework.

After integrating the Industrial Robotic Arm into their production line, they witnessed a remarkable improvement. The robotic arm efficiently handled the welding process, producing consistent and high-quality welds. This resulted in a significant reduction in production time, providing the company with a competitive edge.

*(In-depth Analysis Style)*

The Industrial Robotic Arm’s impact on stamping for press machines is equally remarkable. Stamping, a process that entails the shaping of metal sheets, requires precision and accuracy. Traditionally, this was a labor-intensive task prone to errors. However, with the implementation of the robotic arm, manufacturers have experienced increased efficiency and reduced human error rates.

The integration of the Industrial Robotic Arm into the stamping process has led to improved production rates while maintaining the desired level of quality. This automation not only saves time and costs but also ensures consistent output, regardless of the complexity of the stamped components.

*(Comparative Structure)*

In contrast to manual labor, the Industrial Robotic Arm offers a myriad of advantages. Its tireless work ethic, 24/7 availability, and consistent performance provide an edge over human workers. The robotic arm’s ability to handle heavy loads effortlessly reduces the risk of workplace injuries and enhances overall safety.

Moreover, the Industrial Robotic Arm has the capability to work in hazardous environments, eliminating the need for human intervention. This ensures that employees are out of harm’s way while increasing productivity.

*(Conclusion)*

The Industrial Robotic Arm has undoubtedly revolutionized manufacturing processes. Its contributions in arc welding, stamping for press machines, loading, and unloading have propelled industries into a new era of efficiency and productivity. The precision, accuracy, and reliability of this robotic arm have significantly improved the quality and speed of manufacturing operations worldwide.

Manufacturing companies must embrace the potential of industrial robots to remain competitive in today’s fast-paced market. The Industrial Robotic Arm stands as a testament to the power of automation in increasing productivity, reducing costs, and ensuring consistent quality. As technology continues to advance, it is crucial for industries to adopt these innovative solutions to drive progress and shape the future of manufacturing.

Industrial Robot

“Maximizing efficiency with advanced robotic solutions: Industrial robot palletizer, automatic welding, and 6-axis manipulator arm.”