Industrial Robotic Arm: A Revolution in Manufacturing

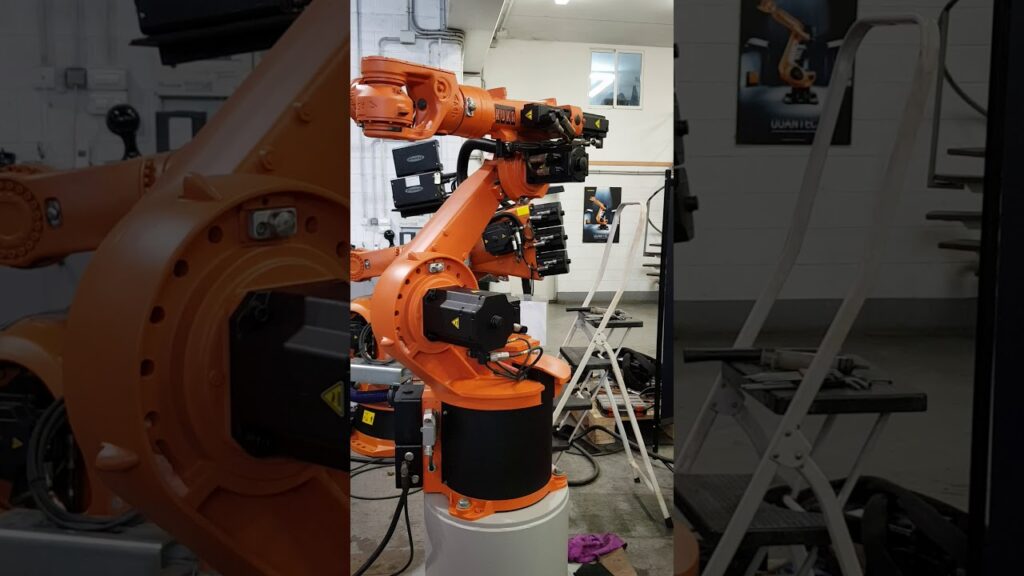

The world of industrial robotics has experienced a groundbreaking advancement with the introduction of the Six axis industrial robot. This remarkable machine is not only fast and accurate but also possesses a 1500 mm arm reach and an impressive 15 kg payload. Coupled with the state-of-the-art KRC1 controller, this industrial robotic arm is transforming the manufacturing industry. In this article, we will explore the capabilities and benefits of this cutting-edge technology.

Industrial robots have become an integral part of many manufacturing processes, automating repetitive tasks and increasing productivity. They are designed to perform tasks with precision and consistency, eliminating the risk of human error. The Six axis industrial robot takes these attributes to new heights, offering a level of speed and accuracy that was previously unimaginable.

One of the standout features of the Six axis industrial robot is its impressive 1500 mm arm reach. This extensive reach allows the robot to operate within a large workspace, accommodating a wide range of manufacturing processes. Whether it is picking and placing objects, welding, or assembly, this industrial robotic arm can handle it all with ease.

With a payload capacity of 15 kg, the Six axis industrial robot is capable of lifting and manipulating heavy objects. This opens up a world of possibilities in industries such as automotive, aerospace, and electronics, where heavy components and materials are common. The ability to handle such weights with precision and speed significantly improves production efficiency.

The KRC1 controller is the brain behind the Six axis industrial robot, providing seamless integration and control. This advanced controller allows for precise programming and operation of the robot, ensuring smooth and accurate movements. It also offers a user-friendly interface, making it easy for operators to set up and modify robot programs as required.

The combination of the Six axis industrial robot and the KRC1 controller has proven to be a game-changer for manufacturers around the world. Its speed, accuracy, and versatility have revolutionized the way factories operate. With this technology, manufacturers can streamline their production processes, reduce labor costs, and increase overall efficiency.

In recent years, the demand for industrial robotic arms has been steadily increasing. Companies are recognizing the benefits of automation and are investing in these advanced technologies to gain a competitive edge. The Six axis industrial robot offers the perfect solution for those looking to enhance their manufacturing capabilities.

In a rapidly evolving industry, it is crucial to stay ahead of the curve. The Six axis industrial robot provides manufacturers with the flexibility and adaptability required to keep up with changing demands. Its ability to handle a wide range of tasks makes it suitable for various industries, from automotive to food and beverage.

Looking ahead, the future of industrial robotics is promising. Technological advancements continue to push the boundaries of what is possible, with robots becoming more intelligent and capable with each passing day. The Six axis industrial robot is leading the charge, setting new standards for speed, accuracy, and payload capacity.

In conclusion, the introduction of the Six axis industrial robot, coupled with the KRC1 controller, has revolutionized the manufacturing industry. With its impressive arm reach and payload capacity, this industrial robotic arm is fast, accurate, and versatile. It offers manufacturers the opportunity to streamline their processes, increase productivity, and improve overall efficiency. As the demand for automation continues to grow, the Six axis industrial robot remains at the forefront of technological innovation. It is a testament to the remarkable advancements made in industrial robotics and a glimpse into the future of manufacturing.

Industrial Robot

“Revolutionizing Automation: Unleashing the Power of Industrial Robotic Arm in Manufacturing Processes”