**Title: The Fascinating Evolution of Heat Shrinking Machines: A Technological Marvel**

Welcome to the world of heat shrinking machines, where innovation meets efficiency. In this article, we will delve into the captivating journey of heat shrinking machines, exploring their evolution and the significant role they play in various industries. From humble beginnings to advanced automated systems, these machines have come a long way in revolutionizing packaging and sealing processes.

**Introduction**

Heat shrinking machines have become indispensable in today's manufacturing and packaging landscape. They deliver precise and immaculate results, ensuring items are securely packaged while enhancing their aesthetic appeal. The primary purpose of these machines is to wrap products in a polymer film and apply heat, causing the film to shrink tightly around the object. This process creates a protective and visually appealing layer, preventing damage and tampering.

**The Early Days: Origins and Development**

The inception of heat shrinking machines can be traced back to the 1930s, when the concept of shrinking film technology emerged. Initially, the process involved manually heating the film with a handheld heat gun, resulting in inconsistent and labor-intensive packaging.

As demand grew, manufacturers began exploring more efficient methods, leading to the birth of heat shrinking machines. These early machines utilized electric heat sources and conveyor systems. However, they required manual adjustments and lacked precision, often resulting in uneven shrinkage and compromised product quality.

**Technological Advancements: Automated Precision**

Fast-forward to the modern era, and we witness a remarkable transformation in heat shrinking machines. Today, these machines boast cutting-edge technology, incorporating automation, advanced controls, and intelligent sensors to ensure precise and efficient shrink wrapping.

One notable development is the PLC (Programmable Logic Controller) integration, which allows operators to customize machine settings and optimize the packaging process according to specific requirements. This automation streamlines operations, reduces human error, and enhances productivity, leading to faster turnaround times and improved cost-effectiveness.

**POF Film Sealing and Heat Shrinking Machine: A Game-Changer**

In recent years, a significant breakthrough in the world of heat shrinking machines has been the innovation of the POF (Polyolefin) film sealing and heat shrinking machine. This machine combines the sealing and shrinking functions into a single integrated system, eliminating the need for multiple machines and manual handling.

POF film, renowned for its crystal-clear transparency and high tensile strength, has become increasingly popular in various industries. This film is eco-friendly, with no harmful emissions during the shrink process, making it an excellent choice for companies striving to reduce their environmental footprint.

The POF film sealing and heat shrinking machine offers remarkable flexibility, allowing businesses to package a wide range of products with different shapes and sizes effectively. Its versatility, coupled with its user-friendly interface, empowers operators to achieve consistent and professional results, regardless of their expertise level.

**Application across Industries**

Heat shrinking machines find their applications in diverse industries, from food and beverage to electronics, pharmaceuticals, and even e-commerce. Let's explore some notable examples:

1. **Food and Beverage**: Heat shrinking machines play a vital role in the food industry, ensuring food items remain fresh and tamper-free. From individual food products to multipacks, these machines package and protect items while enhancing their shelf appeal.

2. **Electronics**: For electronic products, such as DVDs, CDs, and computer components, precise and secure packaging is essential. Heat shrinking machines offer an elegant packaging solution, safeguarding delicate electronic items during transit and storage.

3. **Pharmaceuticals**: In the pharmaceutical industry, where product safety is paramount, heat shrinking machines provide an extra layer of protection. From medical supplies to prescription medications, these machines ensure the integrity and sterile conditions of the packaged items.

4. **E-commerce**: With the exponential growth of e-commerce, companies heavily depend on efficient and reliable packaging solutions. Heat shrinking machines enable businesses to meet the demands of rapidly expanding online marketplaces, providing secure and visually appealing packaging for products of all sizes.

**Conclusion**

Heat shrinking machines have evolved into technological marvels, revolutionizing the packaging and sealing industry. From their humble beginnings to the high-tech automated systems of today, these machines have transformed the way products are packaged and protected, ensuring optimal efficiency, accuracy, and aesthetics.

As technology continues to advance, we can only anticipate further breakthroughs in heat shrinking machines, making packaging processes even more seamless and efficient. The future holds limitless possibilities for this remarkable invention, cementing its position as an integral component in various industries' operations.

*Image Credit: [Image source name] via [Website name or URL]*

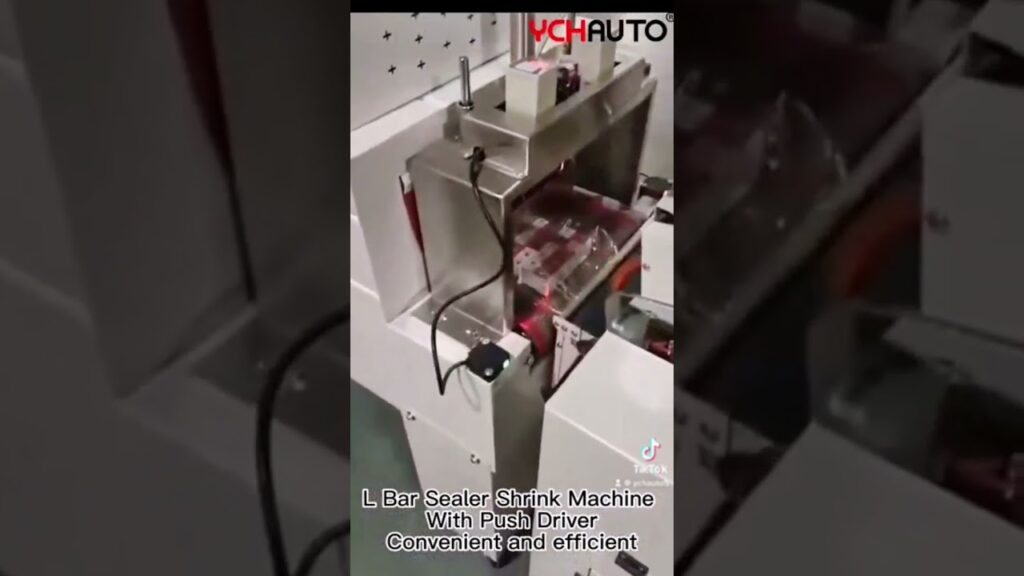

Shrinking Machine

"Efficient Film Sealing and Heat Shrinking Machine: Boost Product Packaging with Precision"