Using Cobots for Efficient Industrial Packing and Stacking

Automation has revolutionized the manufacturing industry, enabling businesses to boost productivity and efficiency like never before. Among the latest advancements in automation technology is the 6-axis industrial manipulator cobot robot arm, a cutting-edge solution that excels in packing and stacking tasks. This article will delve into the capabilities of this innovative robot arm and discuss its benefits for the manufacturing sector.

With the rise of Industry 4.0 and the increasing demand for smart factories, industrial robots have become an indispensable tool for many businesses. The 6-axis industrial manipulator cobot robot arm offers a significant advantage in terms of flexibility and precision. Its ability to mimic human-like movements makes it an ideal tool for intricate tasks such as packing and stacking.

One of the key features of this cobot robot arm is its 6-axis design. This configuration allows for a wide range of movement, providing a high level of dexterity and adaptability. The cobot can easily navigate complex packing configurations and adjust its positioning in real-time. This versatility is particularly valuable in industries where products vary in shape, size, and weight. The cobot can effortlessly handle different objects, reducing the need for manual intervention and minimizing the risk of errors.

In addition to its exceptional agility, the cobot robot arm also boasts good quality construction. Built with durability and reliability in mind, this arm is capable of withstanding the rigors of industrial environments. The materials used ensure longevity and resistance to wear and tear, making it a cost-effective investment that pays off in the long run.

When it comes to packing and stacking, speed and efficiency are crucial. The cobot robot arm excels in these areas, helping businesses meet tight production deadlines and optimize output. By automating packing and stacking processes, manufacturers can significantly increase their productivity and reduce operational costs. Furthermore, with precise motion control and the ability to work at high speeds, the cobot can perform repetitive tasks effortlessly, freeing up human workers to focus on more complex and value-added activities.

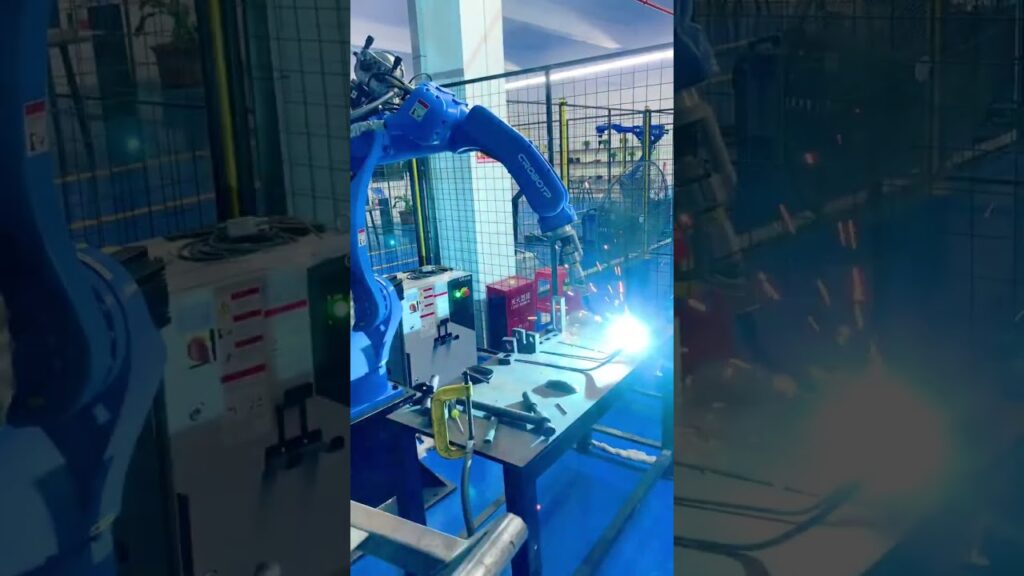

MIG (Metal Inert Gas) welding is one of the many applications where the cobot robot arm can be utilized. Its maneuverability and precision make it an ideal tool for intricate welding tasks. The cobot can easily navigate tight spaces and complex welding patterns, ensuring consistent and high-quality welds. By introducing the cobot into the welding process, manufacturers can improve efficiency, minimize material waste, and enhance overall product quality.

Now, let’s turn our attention to a topic of interest for many businesses considering adopting this technology: the industrial robot price. The cost of industrial robots varies depending on factors such as brand, specifications, and additional features. While it is challenging to provide an exact figure without specific details, it is important to note that the initial investment in the cobot robot arm is often outweighed by the long-term benefits it brings. Increased production output, reduced labor costs, improved product quality, and enhanced worker safety are just a few of the advantages that come with integrating this automation solution into manufacturing processes.

In conclusion, the 6-axis industrial manipulator cobot robot arm offers a game-changing solution for packing, stacking, and various other manufacturing applications. Its flexible design, high precision, and durability make it an invaluable tool in today’s rapidly evolving industrial landscape. By embracing automation and investing in cutting-edge technologies like the cobot, businesses can position themselves for success, achieving greater efficiency, productivity, and competitiveness in the global market.

Disclaimer: The information provided in this article is for general informational purposes only. No claims are made regarding the performance or availability of specific products or services. The industrial robot price mentioned is not specific to any particular manufacturer or supplier. Please consult with industry experts and conduct thorough research before making any purchasing decisions.

Industrial Robot

“Enhancing Efficiency and Performance: Industrial Manipulator Cobots for Precise Packing and Stacking – Unveiling Competitive Pricing”