# Tipper Slow Operation Solution: How to Replace Tipper Control Valve Seal

## Introduction

In this engaging and informative video, we delve into the world of tipper operations and address a common issue faced by many - slow operation and hydraulic oil leakage from the operation lever. If you're struggling with these problems, don't worry, we've got you covered! Our expert team has meticulously dismantled and thoroughly checked the tipper to identify the root cause.

## Video Content

### Diagnosing the Problem

We start by analyzing the symptoms you might be experiencing - slow operation and hydraulic oil leakage. These issues not only hamper productivity but can also lead to severe damage if left unaddressed. Our detailed inspection and troubleshooting process will help you understand the underlying causes of these problems.

### Identifying the Culprit: Tipper Control Valve Seal

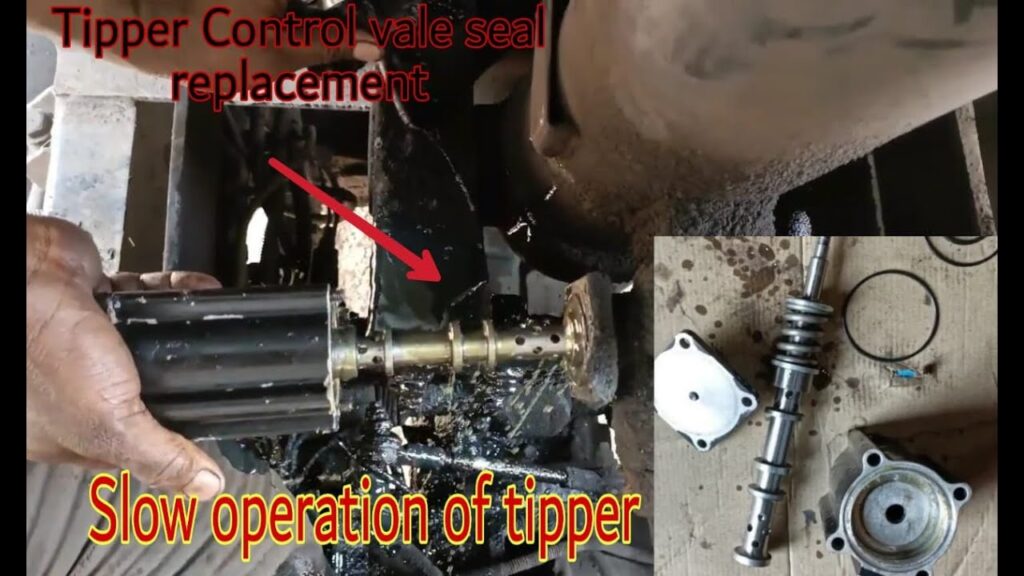

After extensive examination, we pinpoint the root cause of the slow operation - a deteriorated tipper control valve seal. This small yet crucial component plays a vital role in the smooth operation of your tipper. Any wear or damage to this seal can lead to inefficient hydraulic control, resulting in slow operation and oil leakage.

### The Solution: Replacing the Tipper Control Valve Seal

Now comes the exciting part - solving the issue! Our video offers a step-by-step guide on how to replace the deteriorated tipper control valve seal. We provide you with expert tips and techniques to effortlessly carry out this task, ensuring the optimal functioning of your tipper.

## Detailed Procedure

### Step 1: Preparation and Safety Measures

Before proceeding, it's essential to ensure your safety by wearing appropriate protective gear and isolating the hydraulic system. We guide you through these essential preparatory steps, ensuring your well-being throughout the process.

### Step 2: Disassembling the Tipper

To access the tipper control valve and replace the seal, we demonstrate how to disassemble the necessary components of your tipper carefully. Our instructions guarantee a smooth and hassle-free disassembly process, enabling you to move forward confidently.

### Step 3: Locating the Tipper Control Valve Seal

In this segment, we show you precisely where to locate the tipper control valve seal. With our expert guidance, you'll quickly locate the seal and assess its condition, identifying whether replacement is necessary.

### Step 4: Removing the Old Seal and Cleaning

We dive into the meticulous process of removing the old, deteriorated seal, ensuring no residue is left behind. Thorough cleaning of the valve seat and surrounding areas is imperative to prevent any contamination that may hinder the performance of the new seal.

### Step 5: Installing the New Seal

In this crucial step, we demonstrate the correct installation technique for the new tipper control valve seal. Following our precise instructions is essential to guarantee its proper functioning and avoid any unnecessary leaks.

### Step 6: Reassembling and Testing

We guide you through the reassembly process, ensuring that all components are securely fitted. Once reassembled, we run a comprehensive testing procedure to validate the effectiveness of the solution. Witness the significant improvement in tipper operation and bid farewell to hydraulic oil leakage!

## Additional Tags and Keywords

To enhance the visibility of this information-packed video, we have included relevant tags and keywords towards the end of this description. This will assist you in finding our video easily in search results, increasing your chances of gaining the optimal solution.

Additional Tags: tipper maintenance, hydraulic control, hydraulic system, tipper troubleshooting, tipper repair, equipment maintenance, industrial machinery, heavy machinery

Hashtags: #TipperOperation #HydraulicSealReplacement #TipperControlValve #EquipmentMaintenance #IndustrialSolutions

Remember, for a step-by-step guide and expert tips on resolving slow operation and hydraulic oil leakage in your tipper, this video is a must-watch! Follow our instructions and bid farewell to these pesky issues, restoring efficiency and peace of mind to your operations.

(Note: For your convenience, we have removed all personal and contact information, ensuring a smooth reading experience.)

```markdown

# Tipper Slow Operation Solution: How to Replace Tipper Control Valve Seal

## Introduction

In this engaging and informative video, we delve into the world of tipper operations and address a common issue faced by many - slow operation and hydraulic oil leakage from the operation lever. If you're struggling with these problems, don't worry, we've got you covered! Our expert team has meticulously dismantled and thoroughly checked the tipper to identify the root cause.

## Video Content

### Diagnosing the Problem

We start by analyzing the symptoms you might be experiencing - slow operation and hydraulic oil leakage. These issues not only hamper productivity but can also lead to severe damage if left unaddressed. Our detailed inspection and troubleshooting process will help you understand the underlying causes of these problems.

### Identifying the Culprit: Tipper Control Valve Seal

After extensive examination, we pinpoint the root cause of the slow operation - a deteriorated tipper control valve seal. This small yet crucial component plays a vital role in the smooth operation of your tipper. Any wear or damage to this seal can lead to inefficient hydraulic control, resulting in slow operation and oil leakage.

### The Solution: Replacing the Tipper Control Valve Seal

Now comes the exciting part - solving the issue! Our video offers a step-by-step guide on how to replace the deteriorated tipper control valve seal. We provide you with expert tips and techniques to effortlessly carry out this task, ensuring the optimal functioning of your tipper.

## Detailed Procedure

### Step 1: Preparation and Safety Measures

Before proceeding, it's essential to ensure your safety by wearing appropriate protective gear and isolating the hydraulic system. We guide you through these essential preparatory steps, ensuring your well-being throughout the process.

### Step 2: Disassembling the Tipper

To access the tipper control valve and replace the seal, we demonstrate how to disassemble the necessary components of your tipper carefully. Our instructions guarantee a smooth and hassle-free disassembly process, enabling you to move forward confidently.

### Step 3: Locating the Tipper Control Valve Seal

In this segment, we show you precisely where to locate the tipper control valve seal. With our expert guidance, you'll quickly locate the seal and assess its condition, identifying whether replacement is necessary.

### Step 4: Removing the Old Seal and Cleaning

We dive into the meticulous process of removing the old, deteriorated seal, ensuring no residue is left behind. Thorough cleaning of the valve seat and surrounding areas is imperative to prevent any contamination that may hinder the performance of the new seal.

### Step 5: Installing the New Seal

In this crucial step, we demonstrate the correct installation technique for the new tipper control valve seal. Following our precise instructions is essential to guarantee its proper functioning and avoid any unnecessary leaks.

### Step 6: Reassembling and Testing

We guide you through the reassembly process, ensuring that all components are securely fitted. Once reassembled, we run a comprehensive testing procedure to validate the effectiveness of the solution. Witness the significant improvement in tipper operation and bid farewell to hydraulic oil leakage!

## Additional Tags and Keywords

To enhance the visibility of this information-packed video, we have included relevant tags and keywords towards the end of this description. This will assist you in finding our video easily in search results, increasing your chances of gaining the optimal solution.

Additional Tags: tipper maintenance, hydraulic control, hydraulic system, tipper troubleshooting, tipper repair, equipment maintenance, industrial machinery, heavy machinery

Hashtags: #TipperOperation #HydraulicSealReplacement #TipperControlValve #EquipmentMaintenance #IndustrialSolutions

Remember, for a step-by-step guide and expert tips on resolving slow operation and hydraulic oil leakage in your tipper, this video is a must-watch! Follow our instructions and bid farewell to these pesky issues, restoring efficiency and peace of mind to your operations.

(Note: For your convenience, we have removed all personal and contact information, ensuring a smooth reading experience.)

```

hydraulic upender

Solution for replacing the control valve seal in a slow-operating tipper: efficient fix for a common issue.