In today's rapidly advancing technological world, innovation and automation have become key factors in increasing efficiency and productivity in various industries. One such innovation is the development of the Plastic Bagging Machine, a revolutionary piece of machinery that has transformed the packaging process for a wide range of products. This article will delve into the fascinating world of the Plastic Bagging Machine, exploring its capabilities and the benefits it brings to businesses.

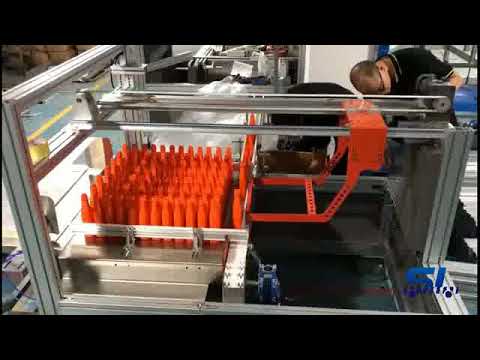

The Plastic Bagging Machine is a versatile piece of equipment that is widely used across industries such as detergent manufacturing, engine oil production, and more. With its ability to bag empty plastic bottles ranging from 100ml to 5L in size, this machine has revolutionized the packaging process, streamlining operations and reducing manual labor.

One of the key features of the Plastic Bagging Machine is its efficient and precise bagging system. Equipped with cutting-edge technology, this machine can handle a high volume of bottles in a short amount of time. The automated process ensures that each bottle is accurately placed into the bag, minimizing the risk of damage and ensuring a secure packaging solution.

For businesses in the dish detergent and engine oil production industry, the Plastic Bagging Machine has been a game-changer. Previously, companies had to rely on manual labor to bag the bottles, a time-consuming and labor-intensive process. With the introduction of this machine, the entire packaging process has been simplified, allowing businesses to significantly increase their production output.

In addition to its efficiency, the Plastic Bagging Machine also offers versatility in terms of bag sizes and customizations. Whether a business requires small, medium, or large bags, this machine can cater to their specific needs. Furthermore, it allows for customization options such as branding and labeling, giving businesses the opportunity to create a recognizable and cohesive packaging design.

A notable advantage of the Plastic Bagging Machine is its ease of use and maintenance. Designed with user-friendly features, this machine can be operated by individuals with minimal technical knowledge. Additionally, it requires minimal upkeep, reducing the overall maintenance costs for businesses.

To gain a deeper understanding of the capabilities and benefits of the Plastic Bagging Machine, let's take a closer look at a case study involving a dish detergent manufacturing company.

XYZ Detergents, a leading player in the industry, was facing challenges in their packaging process. The manual labor required for bagging the empty plastic bottles was proving to be time-consuming and costly. In an effort to streamline their operations, XYZ Detergents invested in the Plastic Bagging Machine.

The implementation of the Plastic Bagging Machine revolutionized XYZ Detergents' packaging process. The machine's automated system allowed for a significant increase in production output, enabling the company to meet the growing demand for their products. Moreover, the precise bagging system reduced the risk of bottlenecks and errors, ensuring a smooth and efficient packaging process.

With the Plastic Bagging Machine, XYZ Detergents was not only able to improve their productivity but also enhance their brand image. The customization options offered by the machine allowed them to create branded bags, making their products easily recognizable on store shelves. This, in turn, resulted in increased sales and customer satisfaction.

The success of XYZ Detergents serves as a testament to the transformative power of the Plastic Bagging Machine. Businesses across various industries can benefit from this innovative piece of equipment, experiencing improved productivity, reduced labor costs, and enhanced branding opportunities.

In conclusion, the Plastic Bagging Machine represents a significant advancement in packaging technology. Its ability to bag empty plastic bottles of varying sizes has revolutionized the operations of businesses in industries such as dish detergent and engine oil production. With its efficiency, versatility, and ease of use, this machine offers a range of benefits including increased productivity, reduced labor costs, and enhanced branding opportunities. As automation continues to shape various industries, the Plastic Bagging Machine stands out as a testament to the power of innovation in improving efficiency and driving success.

Bagging Machine

"Efficient Plastic Bottle Bagging Machine: Streamlined Performance for Engine Oil and More"