Bulk Material Handling Machine: A Comprehensive Session for Enhancing Your Knowledge

With the constant evolution and growth of industries worldwide, the need for efficient bulk material handling systems has become more crucial than ever. These systems play a significant role in ensuring the smooth and seamless movement of various materials, such as grains, powders, ores, and construction aggregates, across different stages of production. In this article, we will delve into a comprehensive session on Bulk Material Handling Machines, exploring their functionalities, benefits, and the innovation they bring to industrial processes.

Bulk material handling systems are used in a variety of industries, including mining, construction, cement, agriculture, and more. Their primary function is to handle large volumes of materials efficiently, ensuring the uninterrupted workflow and productivity of industrial operations. To gain a better understanding of these machines, let’s dive into their functionalities and mechanisms.

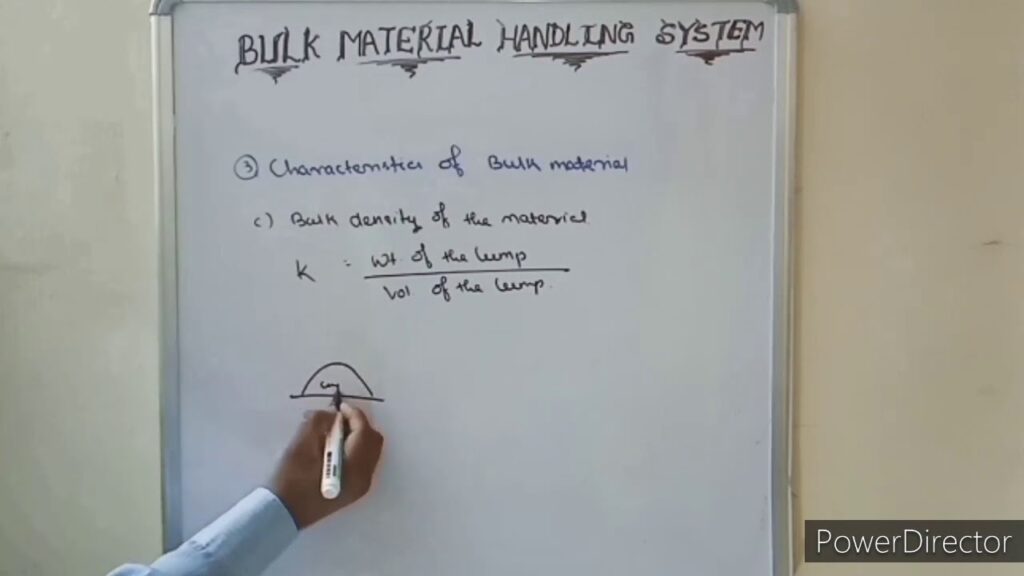

One of the key components of a bulk material handling system is the Bulk Material Handling Machine (BMHS). This machine acts as a reliable and powerful solution for transporting, screening, and storing bulk materials. It consists of different elements that work in tandem to handle materials effectively.

The BMHS typically includes components such as conveyor belts, bucket elevators, stackers, reclaimers, and hoppers. These components are designed to cater to specific material handling requirements, providing optimal solutions for diverse industries.

Conveyor belts are an integral part of the BMHS as they facilitate the movement of bulk materials from one location to another. They can be customized to suit various materials and environments, ensuring efficient transportation while minimizing spillage or contamination.

Bucket elevators, on the other hand, serve the purpose of vertically conveying bulk materials. These machines have buckets attached to a conveyor belt or chain, enabling them to elevate materials to different levels within a facility. They are particularly useful in situations where space is limited or a higher conveying capacity is required.

Stackers and reclaimers are pivotal for efficient storage and retrieval of bulk materials. Stackers are used to create stockpiles by stacking materials in an orderly manner, while reclaimers are employed to retrieve materials from these stockpiles for further processing. Together, they ensure a well-organized and controlled storage system, optimizing space utilization and reducing material loss.

Hoppers, another critical component of the BMHS, receive and hold bulk materials before they are transported to the next stage of production. They are designed to facilitate a steady flow of materials into the system, preventing blockages or disruptions in the workflow.

Now that we have explored the various components of a Bulk Material Handling Machine, let's discuss the benefits and significance of utilizing such systems in industries.

The adoption of BMHS brings several advantages to industrial processes. Firstly, these machines ensure a faster and more efficient movement of materials, reducing manual handling and labor costs. By automating material handling tasks, industries can improve productivity, minimize errors, and enhance overall operational efficiency.

Secondly, BMHS contributes to better workplace safety. By minimizing human intervention in material handling tasks, the risk of accidents or injuries is significantly reduced. Additionally, the use of modern technologies in these systems, such as sensors and alarms, allows for real-time monitoring and intervention, further enhancing safety measures.

Thirdly, bulk material handling systems help optimize space within manufacturing facilities. With their ability to stack materials efficiently and utilize vertical spaces, industries can make the most of their available area, allowing for expansion or diversification of operations.

In conclusion, a comprehensive understanding of Bulk Material Handling Machines is crucial for industries seeking to enhance their material handling processes. These machines offer efficient solutions for the transport, screening, and storage of bulk materials, catering to a wide range of industrial applications. The benefits they bring in terms of increased productivity, workplace safety, and optimal space utilization make them an indispensable asset in modern industries. As the global industrial landscape continues to evolve, the importance of investing in robust and advanced bulk material handling systems, such as the BMHS, cannot be overstated.

Handling Machine

"Efficient Bulk Material Handling: A Comprehensive Overview of Advanced Handling System and Machinery"