Heat Shrinking Machine: Revolutionizing Cable Shrinkage Techniques

The world of technology is constantly evolving, pushing the boundaries of innovation and efficiency. It seems that every day, a new device or machine is introduced into the market that promises to simplify our lives and enhance productivity. One such remarkable invention is the automatic heat shrink tube cutting insertion shrinking machine. This cutting-edge machine not only supports the shrinkage of two wire cables simultaneously but also sets a new standard for efficiency and precision. In this article, we will explore the remarkable capabilities and implications of this revolutionary heat shrinking machine.

Heat shrink technology has been widely used in various industries for years. It involves the process of using heat to shrink plastic tubing around wires, cables, or other components. The benefits of heat shrinking are numerous; it provides insulation, protects against abrasion, and ensures proper cable management. Traditionally, heat shrink tubes were cut and inserted manually, which was a labor-intensive process that often resulted in inconsistencies and human errors.

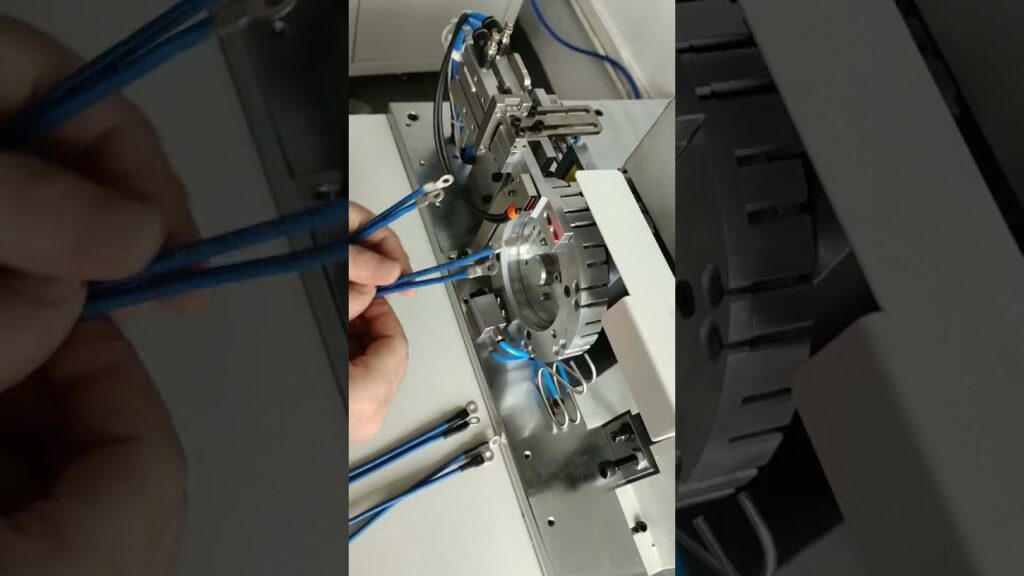

With the introduction of the automatic heat shrink tube cutting insertion shrinking machine, this process has been transformed. This innovative machine streamlines the entire operation, ensuring accuracy and efficiency. By automating the process, it eliminates the need for manual labor, reducing the risk of error and increasing productivity. This machine supports the shrinkage of two wire cables simultaneously, making it a game-changer in industries where time is of the essence.

The automatic heat shrink tube cutting insertion shrinking machine is equipped with advanced features that contribute to its exceptional performance. It is designed with precision-cutting blades that ensure clean and consistent cuts on the heat shrink tubes. Additionally, its insertion mechanism allows for the easy insertion of the cables, reducing the hassle and time required for manual insertion. The shrinkage process is carried out with utmost precision and control, guaranteeing a secure and tight fit around the cables.

One of the most noteworthy aspects of this machine is its user-friendly interface. It is equipped with an intuitive control panel that allows for easy operation and customization. Users can adjust settings such as heat intensity, shrinkage duration, and insertion speed to achieve the desired results. The machine also incorporates safety features to prevent any accidents or damage during operation.

The implications of the automatic heat shrink tube cutting insertion shrinking machine extend beyond its immediate benefits. This technological advancement revolutionizes cable shrinkage techniques, enabling industries to enhance their productivity and operational efficiency. The time and manpower saved through automation can be allocated to other critical tasks, further optimizing the overall workflow. Moreover, the machine's consistent and precise results ensure reliable and durable cable connections, minimizing the risk of failures or malfunctions.

Industries that heavily rely on cable management and insulation, such as electronics, automotive, and telecommunications, stand to gain the most from this innovative machine. The automatic heat shrink tube cutting insertion shrinking machine is a transformative tool for manufacturers, enabling them to streamline their production processes and improve the quality of their products. With the ever-increasing demand for efficiency and reliability, this machine proves to be a valuable asset in meeting customer expectations and staying competitive in the market.

In conclusion, the automatic heat shrink tube cutting insertion shrinking machine is a groundbreaking invention that revolutionizes cable shrinkage techniques. Its ability to support the shrinkage of two wire cables simultaneously, coupled with its precision and efficiency, makes it a game-changer in various industries. This machine not only saves time and labor but also improves the overall quality and reliability of cable connections. As technology continues to advance at an unprecedented pace, it is innovations like these that contribute to the progress of industries worldwide.

Shrinking Machine

"Efficient and Precise Heat Shrink Tube Cutting and Inserting with Advanced Heat Shrinking Machine"