Stretch wrapping is a common method used in the packaging industry to securely wrap products on pallets. It ensures that the goods remain stable during transportation and storage, preventing any damage that may occur from shifting or falling off the pallet. One of the widely used machines for stretch wrapping is the Orbital Stretch Wrapping Machine. In this article, we will explore the features and benefits of this machine and understand why it is a popular choice among businesses.

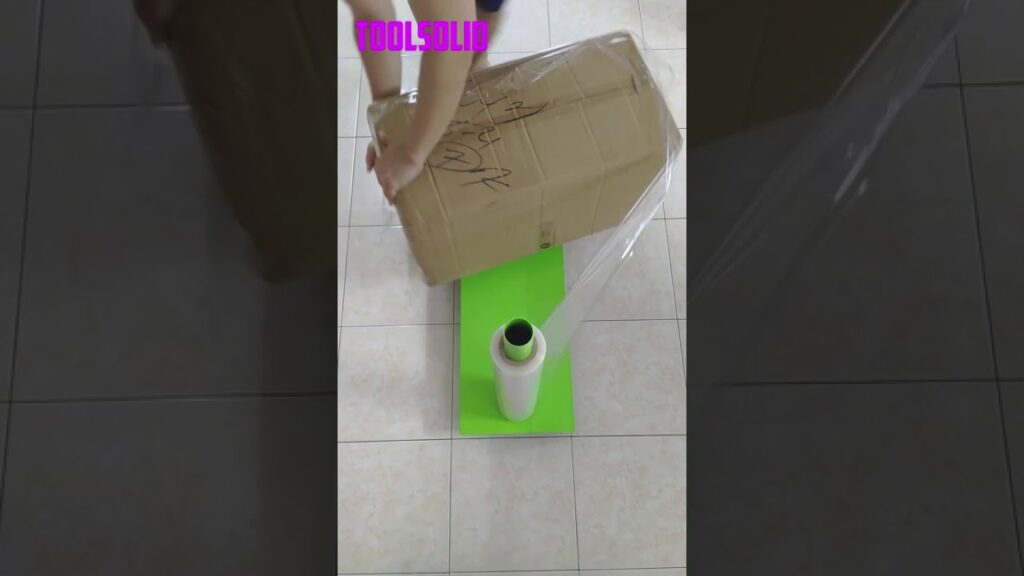

The Orbital Stretch Wrapping Machine is a versatile and efficient piece of equipment that is designed to wrap cylindrical or rectangular shaped products securely. It works by revolving the product around its horizontal axis while simultaneously applying stretch film around it. This wrapping technique provides superior load containment, as the film's tension can be adjusted based on the specific requirements of the product being wrapped.

One key feature of the Orbital Stretch Wrapping Machine is its ability to handle a wide range of product sizes and shapes. Whether it's pipes, rods, cylinders, or even irregularly shaped products, this machine can efficiently wrap them all. The adjustable parameters allow businesses to customize the wrapping process to suit their unique product dimensions, ensuring a tight and secure wrap every time.

Another advantage of the Orbital Stretch Wrapping Machine is its speed and efficiency. With its automated wrapping process, it can wrap multiple products within a short period, significantly reducing the time and effort required compared to manual wrapping. This not only improves productivity but also reduces labor costs for businesses.

The use of stretch film is integral to the working of the Orbital Stretch Wrapping Machine. Stretch film is a specialized plastic film that has elastic properties, allowing it to stretch and adapt to the contours of the product being wrapped. It provides an extra layer of protection, keeping the products safe from dust, moisture, and other external elements during transit and storage.

When it comes to choosing the right stretch film, it is essential to consider various factors such as the type of product, the storage conditions, and the transportation method. Selecting the appropriate stretch film ensures that the products are properly secured and protected, minimizing the risk of damage. There are various types of stretch films available in the market, including hand stretch films, machine stretch films, and pre-stretched films, each catering to specific requirements.

The Orbital Stretch Wrapping Machine can be used with different types of stretch films, making it a versatile option for businesses. It offers compatibility with both hand stretch films and machine stretch films, allowing businesses the flexibility to choose the most suitable film based on their needs. This compatibility ensures that customers have options and can select the stretch film that best meets their product packaging requirements.

Furthermore, investing in an Orbital Stretch Wrapping Machine can lead to substantial cost savings for businesses. By automating the wrapping process, it eliminates the need for manual labor, reducing associated costs. Additionally, using stretch film instead of traditional methods like strapping or shrink wrapping can reduce material costs. Stretch film is typically more cost-effective and requires less material to achieve the desired level of load containment.

In conclusion, the Orbital Stretch Wrapping Machine is a valuable asset for businesses in the packaging industry. Its versatility, speed, and efficiency make it an excellent choice for securely wrapping a wide range of products. By investing in this technology, businesses can improve productivity, reduce labor costs, and ensure that their products are safely transported and stored. Combined with the right stretch film, the Orbital Stretch Wrapping Machine offers a comprehensive packaging solution that meets the unique needs of businesses across various industries.

Orbital Stretch Wrapper

"Efficient and Reliable Wrapping Machines: Enhancing Packaging Efficiency with Stretch Film and Orbital Wrapping Technology"