Introduction:

Industrial robotics has revolutionized the manufacturing industry, streamlining production processes and reducing human labor. In the course "Industrial Robotics with Python," various parameters related to technical specifications and the types of industrial robots are discussed. This article aims to provide a comprehensive overview of these parameters, enabling readers to gain a deeper understanding of the subject.

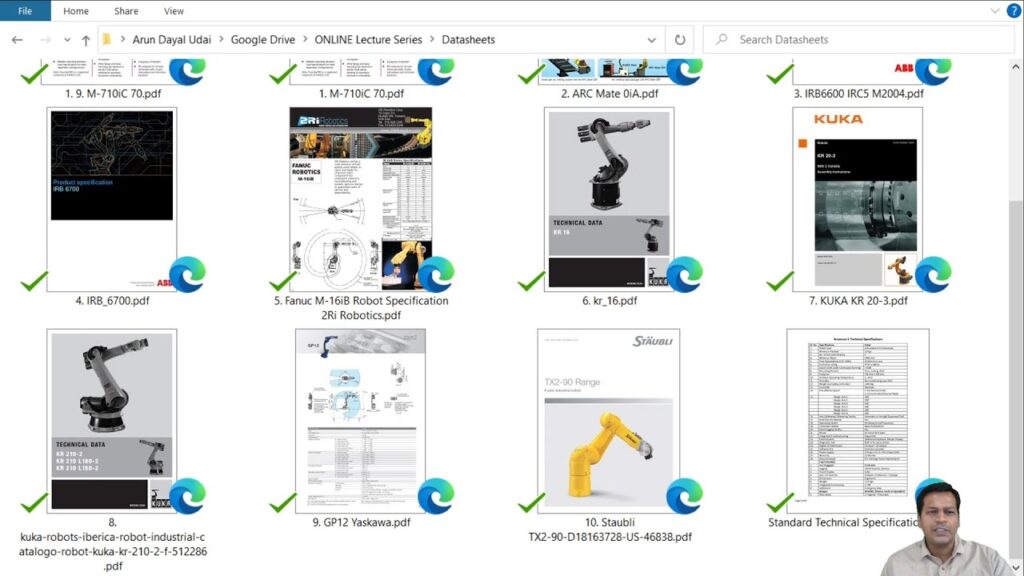

Technical Specifications of an Industrial Robot:

When it comes to industrial robots, understanding their technical specifications is crucial for selecting the right one for a particular application. Let's explore some important parameters that are covered in the "Industrial Robotics with Python" course.

1. Payload Capacity:

The payload capacity of an industrial robot refers to the maximum weight it can handle during operation. It is imperative to consider this specification to ensure that the robot can effectively handle the materials or components required for a specific task. The course provides insights into how to calculate the payload capacity and ensure optimal performance.

2. Reach and Workspace:

The reach of an industrial robot determines the maximum distance it can travel while performing its tasks. The workspace, on the other hand, corresponds to the area covered by the robot. Both these specifications play a crucial role in defining the robot's flexibility and its suitability for various applications. The course dives into the details of reach and workspace, enabling learners to understand the practical implications.

3. Accuracy and Repeatability:

Precision is essential in industrial processes, and industrial robots are no exception. Accuracy refers to the ability of a robot to reach a desired position accurately. Repeatability, on the other hand, represents the robot's consistency in returning to the same position repeatedly. The course sheds light on how both these parameters are measured and their significance in industrial automation.

Types of Industrial Robots:

In addition to technical specifications, the course on "Industrial Robotics with Python" also covers different types of industrial robots. Let's explore a few common types discussed in the course:

1. Articulated Robots:

These robots consist of rotary joints, mimicking the movement of a human arm. Articulated robots provide great flexibility and are widely used in assembly lines, welding, and material handling applications. The course delves into the kinematics and control strategies for articulated robots.

2. SCARA Robots:

SCARA stands for Selective Compliance Assembly Robot Arm. These robots are known for their fast and precise movements, making them suitable for tasks requiring high-speed operations. The course explains the unique mechanical structure and programming aspects associated with SCARA robots.

3. Cartesian Robots:

Also known as gantry robots, Cartesian robots operate on a three-axis linear system. They excel in applications that require heavy lifting and precise movements along a fixed path. The course explores the programming techniques and optimization approaches for these robots.

4. Delta Robots:

Delta robots are known for their exceptional speed, making them ideal for pick-and-place operations in industries such as food packaging and electronics. The course provides insights into the inverse kinematics and motion control of delta robots.

Conclusion:

The "Industrial Robotics with Python" course offers a comprehensive understanding of both technical specifications and types of industrial robots. By exploring parameters like payload capacity, reach, accuracy, and repeatability, learners can make informed decisions while selecting an industrial robot for a particular task. Additionally, the course dives into the intricacies of articulated robots, SCARA robots, Cartesian robots, and delta robots, helping individuals develop a broad knowledge base in industrial robotics. With this newfound knowledge, manufacturers can leverage the power of industrial robots to enhance productivity, efficiency, and overall manufacturing processes.

Industrial Robot

"Unveiling the Deep Insights: Understanding Technical Specs and Various Types of Industrial Robots for Efficient Operations"