The Advancement of Strapping Machines

Strapping machines, also known as binding machines, have become an essential tool in numerous industries, streamlining the packaging process and enhancing efficiency. With the rapid advancement of technology, these machines have undergone significant improvements, making them indispensable for businesses worldwide. In this article, we will delve into the features and benefits of strapping machines, specifically focusing on the Compact Automatic Binding & Strapping machines developed by BINDTEC CO., LTD.

In recent years, the demand for strapping machines has surged due to their ability to securely strap packages, bundles, and pallets. Strapping not only adds stability but also provides protection during transportation, minimizing the risk of damage. The Compact Automatic Binding & Strapping machines from BINDTEC offer an innovative solution for streamlining packaging operations.

The Enhanced Efficiency of Strapping Machines

One of the key advantages of strapping machines is their ability to automate the binding process, eliminating the need for manual labor. This not only saves time but also reduces the risk of injuries associated with manual strapping. The Compact Automatic Binding & Strapping machines by BINDTEC are equipped with advanced technology, ensuring seamless operation and high productivity.

These machines are capable of handling various materials, including paper, cardboard, and plastic. This versatility makes them suitable for a wide range of industries, catering to different packaging needs. Whether it’s bundling stacks of paper in a printing press or securing cartons in a distribution center, these strapping machines perform with precision and efficiency.

Additionally, the Compact Automatic Binding & Strapping machines are designed to be user-friendly, allowing even those without technical expertise to operate them. The intuitive interface and easy-to-understand controls ensure convenience and minimal training requirements.

The Superior Features of BINDTEC CO., LTD’s Strapping Machines

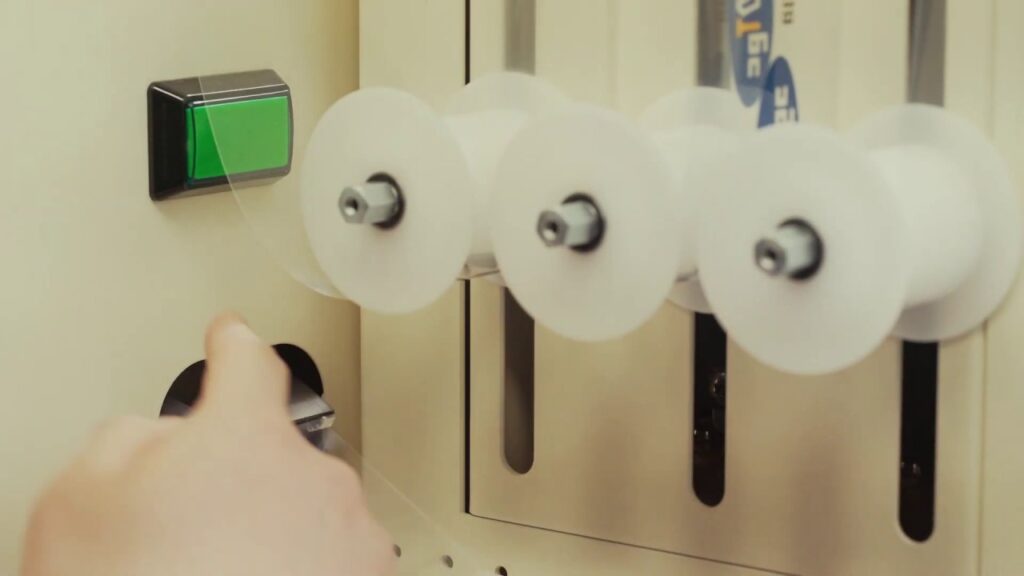

BINDTEC CO., LTD has gained recognition for its commitment to innovation and product quality. Their Compact Automatic Binding & Strapping machines are a testament to their dedication. Let’s take a closer look at some of the key features that set these machines apart.

1. Automatic Banding: The strapping machines from BINDTEC are equipped with an automatic banding system, which eliminates manual intervention. This feature ensures consistent tension and tightness of the straps, resulting in secure packaging every time.

2. Adjustable Strapping Parameters: These machines allow users to customize the strapping parameters, such as tension, speed, and length, according to their specific requirements. This flexibility ensures optimal performance in diverse packaging scenarios.

3. Strap Detection and Correction: In the event of a misaligned or improperly fed strap, the machine’s intelligent detection system identifies the error and automatically corrects it. This feature minimizes downtime and prevents wastage of materials.

4. Compact Design: The Compact Automatic Binding & Strapping machines have been designed with space efficiency in mind. Their compact footprint allows them to be easily integrated into existing packaging lines or workstations without requiring significant alterations.

The Future of Strapping Machines

As technology continues to evolve, the future of strapping machines looks promising. Many industry experts predict that advancements in artificial intelligence and automation will revolutionize the packaging industry. These developments might include more sophisticated strapping machines equipped with machine learning capabilities, self-diagnosis systems, and remote monitoring options.

Furthermore, the demand for sustainable packaging solutions has been on the rise. Strapping machines can play a crucial role in achieving this goal by utilizing eco-friendly materials and optimizing the consumption of straps. Manufacturers like BINDTEC CO., LTD are likely to contribute to this trend by developing innovative solutions that align with sustainability goals.

In Conclusion

Strapping machines have come a long way from their humble beginnings. From simple manual tools to sophisticated automatic systems, they have greatly enhanced the efficiency and reliability of the packaging process. BINDTEC CO., LTD’s Compact Automatic Binding & Strapping machines exemplify the advancements in this field, providing businesses with a reliable and cost-effective solution.

As we look towards the future, it is clear that strapping machines will continue to evolve and adapt to the changing needs of the industry. With technologies such as automation, artificial intelligence, and sustainable practices, the potential for improvement is tremendous. As businesses strive for greater efficiency and sustainability, these machines will undoubtedly play a vital role in achieving those goals.

Strapping Machines

“Efficient and Reliable Compact Automatic Binding & Strapping Machines: Optimize Your Packaging Process”