Handling Machine Manufacturers: Revolutionizing Coil Processing with Custom Lift Tables

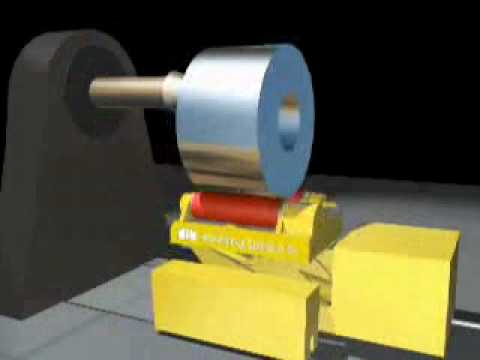

Coil processing plays a vital role in various industries, including automotive, construction, and manufacturing. Handling Specialty, a pioneer in the field of handling solutions, has developed a groundbreaking custom lift table specifically designed for coil entry and exit handling. This innovative equipment offers unparalleled efficiency and safety, transforming the way coil processing operations are conducted.

The Handling Specialty lift table is a game-changer in the realm of coil processing equipment. It addresses the unique challenges faced by manufacturers in terms of handling heavy coils with precision and care. Whether it's steel, aluminum, or other metals, this lift table is capable of accommodating a wide range of coil sizes and weights.

One of the standout features of the Handling Specialty lift table is its robust construction, which ensures reliable performance even under demanding conditions. The design incorporates high-quality materials, meticulous engineering, and thorough testing, guaranteeing the utmost durability and longevity. This level of durability translates into fewer maintenance requirements and reduced downtime, ultimately contributing to enhanced productivity for manufacturers.

In addition to its impressive build quality, the Handling Specialty lift table boasts an intuitive and user-friendly interface. This aspect greatly simplifies its operation, enabling operators to quickly adapt to its functionalities. Furthermore, the lift table is equipped with advanced safety features, such as interlocks, emergency stop buttons, and anti-slip surfaces, ensuring optimum protection for both the operator and the coils being handled.

With the Handling Specialty lift table, the coil entry and exit handling process has become significantly more efficient. Its innovative lifting mechanism allows for precise positioning and manipulation of coils, eliminating the need for manual labor and reducing the risk of injuries. This not only enhances workplace safety but also improves overall operational efficiency.

Furthermore, the Handling Specialty lift table excels in terms of adaptability. Its customizable design enables manufacturers to tailor the lift table to their specific requirements, ensuring seamless integration into existing workflows. Whether it's specific coil sizes, specialized coatings, or additional safety features, this lift table can be customized to meet the unique needs of different industries and applications.

To better understand the revolutionary impact of the Handling Specialty lift table, let us delve into a case study. ABC Manufacturing, a leading automotive component manufacturer, was grappling with the inefficiencies and safety concerns of their existing coil processing setup. However, upon implementing the Handling Specialty lift table, they experienced a remarkable transformation.

By utilizing the lift table's precision handling capabilities, ABC Manufacturing was able to streamline their coil entry and exit processes significantly. The enhanced efficiency and reduced reliance on manual labor resulted in substantial cost savings and improved overall productivity. Moreover, the lift table's adaptable design allowed ABC Manufacturing to seamlessly integrate it into their existing production line, without any disruption to their operations.

The impact of the Handling Specialty lift table on coil processing operations is undeniable. Its innovative features, robust construction, and customizable design make it an unrivaled solution for manufacturers in various industries. As the global market becomes increasingly demanding, this lift table empowers handling machine manufacturers to optimize their production processes and stay ahead of the competition.

In conclusion, the custom lift table for coil processing entry handling and coil exit handling, designed and manufactured by Handling Specialty, has revolutionized the way manufacturers approach coil processing. Its exceptional build quality, user-friendly interface, and customizable design make it an invaluable asset for handling machine manufacturers worldwide. By investing in this innovative equipment, manufacturers can elevate their coil processing operations to new heights of efficiency, safety, and productivity.

Handling Machine

"Maximizing Efficiency: Innovations in Coil Entry, Exit, and Handling Machines - Experts in Coil Processing Equipment Share Insights"