The Importance of a Good Material Handling System

Introduction to Material Handling

Material handling is an essential aspect of any manufacturing or distribution process. It involves the movement, storage, control, and protection of materials within a facility. A well-designed material handling system is crucial for the smooth operation of businesses, as it directly impacts productivity, efficiency, and cost-effectiveness.

Handling Equipment

Handling equipment plays a crucial role in material handling systems. It includes a wide range of machinery and tools used for the transportation, sorting, and storage of materials. Some common examples of handling equipment are forklifts, conveyors, cranes, pallet jacks, and automated guided vehicles (AGVs). These machines are designed to streamline tasks, reduce manual labor, and ensure the safe handling of materials.

Why a Good Material Handling System is Essential

A good material handling system is essential for several reasons. Firstly, it enhances productivity by reducing the time and effort required to move materials. By utilizing efficient handling equipment, workers can complete tasks quickly, allowing for a higher volume of production. This directly translates to increased output and improved customer satisfaction.

Secondly, an effective material handling system improves workplace safety. Accidents and injuries can occur when materials are mishandled or improperly stored. By implementing proper handling equipment and methodologies, risks can be mitigated, ensuring the well-being of employees and minimizing the potential for accidents.

Thirdly, an optimized material handling system leads to cost savings. When materials are efficiently stored, transported, and processed, wastage is minimized. Additionally, handling equipment such as AGVs can automate repetitive tasks, reducing labor costs. Overall, a well-designed system helps businesses save money, making them more competitive in the market.

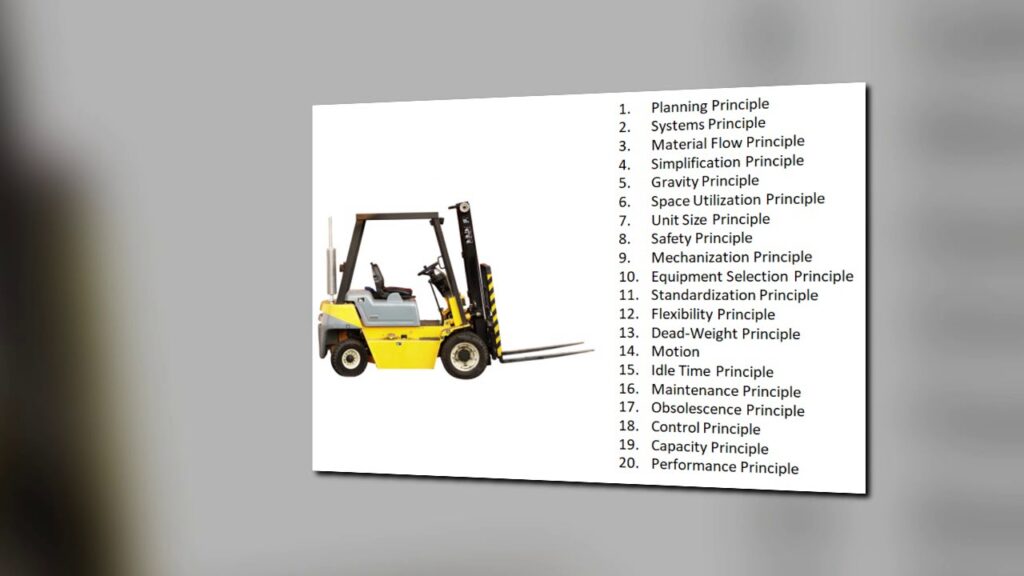

Principles Guiding Material Handling Systems

There are several principles that guide the design and implementation of material handling systems. These principles aim to maximize efficiency, minimize risks, and ensure a smooth flow of materials within a facility.

1. Planning: A good material handling system starts with proper planning. This involves assessing the facility’s requirements, defining goals, and identifying potential challenges. By thoroughly understanding the needs of the operation, a suitable handling system can be devised.

2. Flexibility: A material handling system should be flexible to accommodate changes in demand or production processes. Designing a system that can adapt to varying requirements ensures long-term efficiency and scalability.

3. Integration: Material handling systems should be integrated with other aspects of the business, such as inventory management, production planning, and transportation. This ensures a seamless flow of materials throughout the supply chain.

4. Ergonomics: Consideration should be given to the ergonomics of the system. By designing workstations and providing equipment that supports the physical well-being of employees, efficiency and safety can be enhanced.

5. Sustainability: Material handling systems should be designed with sustainability in mind. This involves using energy-efficient equipment, reducing waste, and implementing recycling practices.

In conclusion, a good material handling system is essential for the smooth operation of businesses. With the right handling equipment and adherence to the principles guiding material handling systems, businesses can achieve increased productivity, improved workplace safety, and significant cost savings. Therefore, investing in a well-designed system is vital for long-term success in any industry.

Handling Machine

“Streamlining Material Handling Processes: An Essential Primer on Handling Equipment”