Robotic technology has been revolutionizing industries across the globe, and the different types of industrial robots have played a key role in this transformation. In this article, we will explore the various configurations of industrial robots and their applications in different sectors.

The world of industrial robotics is vast and diverse, with robots designed to perform a wide range of tasks. From manufacturing to healthcare, these robots have proven to be instrumental in increasing productivity, efficiency, and safety. Let's dive into the different types of industrial robots and understand how they are making a difference.

1. Cartesian Robots:

Also known as gantry robots, Cartesian robots have three linear axes that move in a straight line along the X, Y, and Z-axis. They are highly versatile and can be programmed to carry out precise and repetitive tasks such as assembly, welding, and material handling. Cartesian robots are commonly used in automotive, electronics, and packaging industries.

2. SCARA Robots:

SCARA stands for Selective Compliance Assembly Robot Arm. These robots have four axes of movement, with a combination of rotational and linear motion. SCARA robots are known for their speed and precision, making them ideal for tasks that require fast and accurate assembly, pick-and-place operations, and high-speed packaging. They are commonly found in industries like electronics, pharmaceuticals, and food processing.

3. Delta Robots:

Delta robots feature a unique design with three parallel arms connected to a base. They are lightweight, fast, and highly flexible. Delta robots are extensively used in applications that demand high-speed pick-and-place operations, such as packaging, sorting, and material handling in the food and beverage industry.

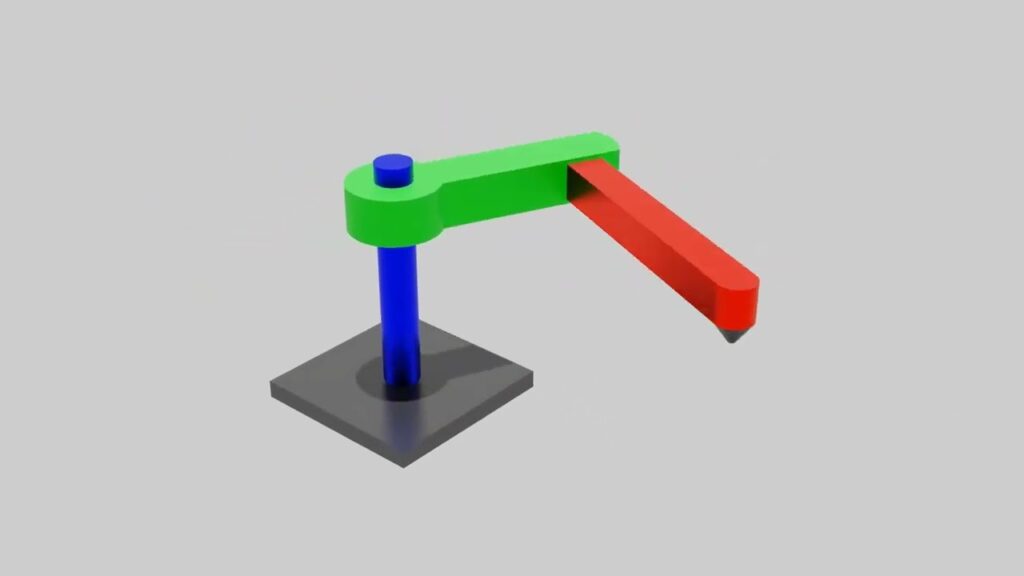

4. Articulated Robots:

Articulated robots mimic the movements of a human arm with multiple joints and rotary motion. These robots have a high degree of freedom, making them suitable for complex tasks that require flexibility and dexterity. Articulated robots are commonly used in welding, painting, and material handling in industries like automotive, aerospace, and construction.

5. Collaborative Robots:

Also known as cobots, collaborative robots are designed to work alongside humans in a shared workspace. Cobots are equipped with advanced sensors and safety features to ensure safe collaboration with humans. They are versatile and can perform various tasks including assembly, pick-and-place, and quality inspection. Collaborative robots have gained popularity across industries due to their ability to enhance productivity while ensuring a safe working environment.

6. Mobile Robots:

Mobile robots are autonomous robots that have the ability to move freely within a defined area. They are equipped with sensors and navigation systems to navigate their surroundings without human intervention. Mobile robots are used in industrial environments for tasks such as material transport, inventory management, and inspection. These robots are particularly useful in large warehouses and logistics facilities.

7. Exoskeleton Robots:

Exoskeleton robots are a recent development in the field of industrial robotics. They are wearable robotic suits that enhance the strength and endurance of the user. Exoskeleton robots find applications in industries that involve physically demanding tasks, such as heavy lifting and repetitive movements. They can reduce the risk of injuries and improve ergonomics for workers.

The types of industrial robots mentioned above are just a glimpse of the incredible advancements in robotic technology. With continuous innovation and research, the capabilities of industrial robots are only expected to grow. These robots have not only increased efficiency and productivity but have also paved the way for safer work environments.

In conclusion, the different types of industrial robots have brought immense benefits to various industries. From Cartesian robots' versatility to collaborative robots' ability to work alongside humans, each configuration serves a specific purpose. The advancements in robotic technology have undoubtedly revolutionized industries, and we can only anticipate even more exciting developments in the future.

Sources:

- [Types of Industrial Robots](insert source here)

- [Types of Industrial Robots](insert source here)

Industrial Robot

"Exploring the World of Industrial Robotics: A Comprehensive Guide to Different Types and Applications"