Mould Turning Machine: Optimizing Efficiency and Precision in the Die/Mould Industry

Are you looking to enhance productivity and accuracy in your die/mould manufacturing process? Look no further than the revolutionary Mould Turning Machine! In this video, we delve into the world of die/mould turning and uncover the myriad benefits this cutting-edge technology brings to the industry.

Overview

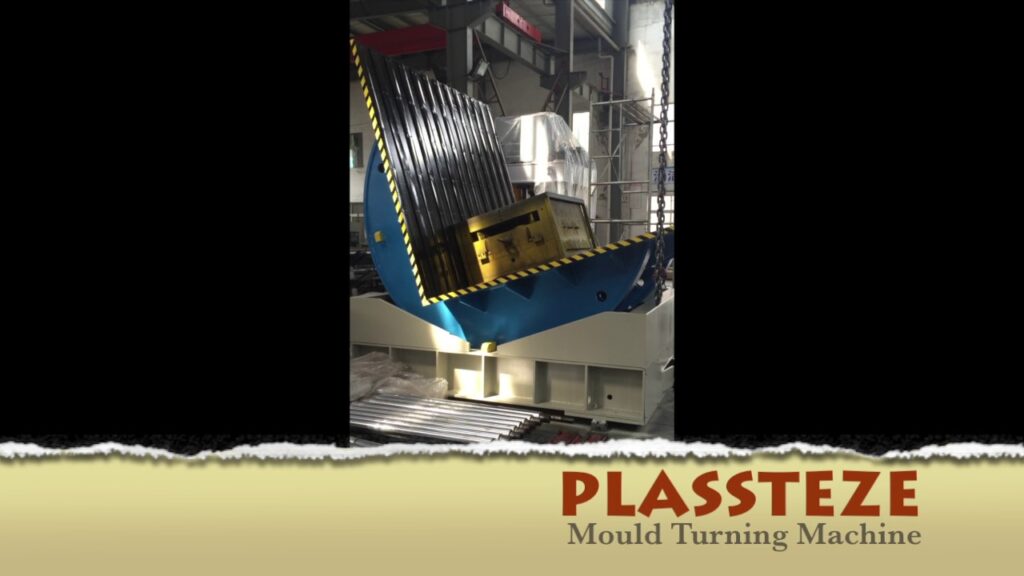

The Mould Turning Machine plays a vital role in the post-production stage of the die/mould manufacturing process. Once the moulds are dismounted from the moulding/die casting machines, they need to be turned 90 degrees to enable easy access for further operations, such as cleaning, maintenance, or modification.

Efficiency is a top priority in the die/mould manufacturing industry, and the Mould Turning Machine excels in streamlining this crucial process. With its advanced features and precise functionality, this state-of-the-art equipment allows for seamless and quick alignment of the moulds, greatly reducing downtime and increasing production capacity.

Why Choose the Mould Turning Machine?

1. Unparalleled Precision: The Mould Turning Machine ensures precise 90-degree rotation, guaranteeing accurate placement of the moulds. This eliminates any misalignment issues, resulting in enhanced product quality and reduced scrap rates. The machine’s robust construction and advanced control systems contribute to its unmatched precision.

2. Increased Efficiency: By incorporating the Mould Turning Machine into your die/mould manufacturing process, you can significantly improve efficiency. No longer will you waste valuable time manually rotating moulds, as this automated solution completes the task swiftly and flawlessly. This allows for faster turnaround times, optimizing productivity and ultimately increasing profitability.

3. Enhanced Worker Safety: Prioritizing the safety of your personnel is of utmost importance. With the Mould Turning Machine, you minimize the risks associated with manual mould rotation, such as strain injuries and accidents. By automating this task, you provide a safer working environment and promote the overall well-being of your team.

Additional Benefits and Advantages

– Versatility: The Mould Turning Machine can handle a wide range of mould sizes and configurations, making it suitable for diverse die/mould manufacturing applications. Whether you deal with injection moulds, blow moulds, or any other type of mould, this equipment has you covered.

– Time-Saving: Automating the mould turning process significantly reduces overall production time, allowing you to meet tight deadlines and fulfill customer orders promptly. Minimizing the turnaround time enhances customer satisfaction and strengthens your reputation in the market.

– Cost-Effective: By incorporating the Mould Turning Machine into your operations, you can optimize resource utilization and reduce labor costs. The machine’s efficiency and precision translate into reduced material waste and improved workflow, leading to substantial cost savings in the long run.

Conclusion

The Mould Turning Machine revolutionizes the die/mould manufacturing process by providing an efficient and precise solution for post-production mould rotation. With its unparalleled precision, increased efficiency, and enhanced worker safety, this cutting-edge technology is an indispensable asset for any die/mould manufacturing facility.

Embrace the power of automation and experience improved productivity like never before. Invest in the Mould Turning Machine and witness a seamless transformation in your die/mould manufacturing operations. Take a step towards excellence, reliability, and profitability.

Keywords: Mould Turning Machine, die/mould manufacturing, precision, efficiency, automation, worker safety, versatility, time-saving, cost-effective.

Hashtags: #MouldTurningMachine #DieMouldManufacturing #EfficiencyRevolution #AutomationAdvantage

Mold Upender

“Compact Mold Rotator”