The Industrial Robot Resembling a Human Hand

Industrial robots have been transforming the manufacturing industry since their inception. Designed to perform repetitive tasks with precision and efficiency, these machines have revolutionized production processes. The evolution of industrial robots has been nothing short of remarkable, with advancements in technology enabling them to mimic human actions and even resemble a human hand.

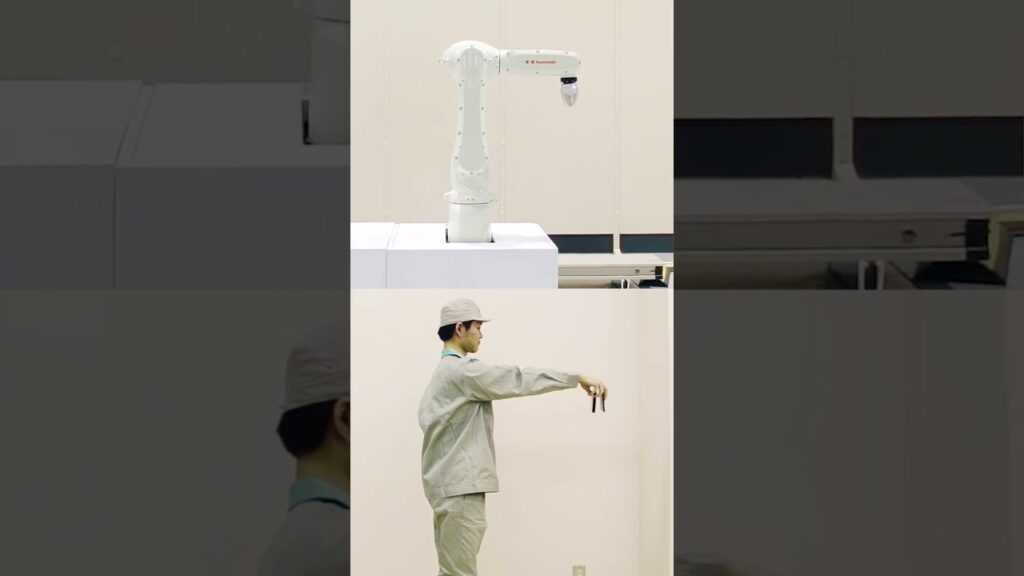

In a recent YouTube video by Kawasaki, one of the leading brands in industrial robotics, we get a glimpse into the incredible capabilities of their industrial robot. The video showcases a robot that closely resembles a human hand, complete with individual finger-like appendages and a wide range of movements. This fascinating display of technology highlights the potential for robots to perform intricate tasks that were once exclusive to human workers.

The robot, equipped with state-of-the-art sensors and actuators, can simulate a variety of gestures and motions. It effortlessly picks up objects, manipulates them with precision, and places them in designated locations. The level of dexterity and control demonstrated by this robotic hand is truly impressive, making it suitable for a wide range of applications in industries such as electronics, automotive, and healthcare.

This innovative technology can revolutionize assembly lines, where delicate components and intricate tasks demand a high level of precision. By employing industrial robots that resemble human hands, manufacturers can significantly enhance efficiency and product quality. These robots can perform tasks that were traditionally only possible for skilled human workers, eliminating the risk of human errors and ensuring consistent results.

The Types of Industrial Robots

Industrial robots come in various forms and configurations, each designed for specific applications and tasks. Understanding the different types can help manufacturers choose the most suitable robot for their needs. Let’s explore some of the common types of industrial robots:

1. Cartesian Robots: Also known as gantry robots, these robots feature a three-dimensional rectangular coordinate system. They move along linear paths with straight lines, making them ideal for pick-and-place operations and assembly tasks.

2. SCARA Robots: Selective Compliance Assembly Robot Arms (SCARA) are designed for tasks that require fast and precise movements. These robots have a horizontal shoulder, an elbow joint, and a rotary wrist, allowing them to perform operations such as sorting, packaging, and assembly.

3. Delta Robots: Delta robots are known for their exceptional speed and agility. They consist of three arms connected to a central base, forming a pyramid shape. Delta robots excel in tasks that require rapid picking and placing of small items, making them ideal for applications in the food and pharmaceutical industries.

4. Articulated Robots: The most common type of industrial robot, articulated robots have joints and links that mimic the movements of a human arm. They can perform a wide range of tasks, from welding and painting to material handling and assembly. The robot showcased in the Kawasaki video falls under this category.

2 Robot Axes: 5, 6, or 7?

When it comes to industrial robots, the number of axes refers to the degrees of freedom or the range of motion the robot has. The video above features a robot with what appears to be at least six axes. Each axis represents a rotational or linear movement, allowing the robot to move in multiple directions and angles.

Robots with five axes are commonly used in applications that require straightforward movements along X, Y, and Z axes, with additional rotation on the wrist. These robots are efficient for tasks such as welding, material handling, and machine tending.

Six-axis robots, like the one showcased in the video, offer increased flexibility and versatility. They can perform more complex tasks that require intricate movements and access to hard-to-reach areas. With the addition of an extra rotational axis on the robot wrist, these machines excel in tasks like assembly, painting, and inspection.

Some advanced robots even have seven or more axes, providing even greater degrees of freedom and flexibility. These robots can perform highly complex and precise operations, making them suitable for industries such as aerospace and medical devices.

The Future of Industrial Robotics

The development of industrial robots that resemble human hands marks an exciting chapter in the evolution of automation. As technology continues to advance at an unprecedented rate, we can expect even more sophisticated and capable robots to enter the workforce.

With the merging of robotics and artificial intelligence, robots are becoming smarter, more adaptable, and capable of learning from their environment. This opens up a realm of possibilities for collaborative robots, or cobots, that can work alongside human workers, enhancing productivity and safety.

As the demand for advanced automation grows, it is crucial for manufacturers to stay updated with the latest advancements in industrial robotics. By embracing these technologies, companies can streamline their operations, increase efficiency, and remain competitive in an ever-evolving marketplace.

In conclusion, the industrial robot resembling a human hand showcased in the YouTube video by Kawasaki is a testament to the rapid progress being made in the field of robotics. The ability to mimic human movements and perform intricate tasks opens up new possibilities for industries across the globe. With robots becoming increasingly sophisticated, it is clear that they will play a vital role in shaping the future of manufacturing and automation.

Industrial Robot

“Choosing the Perfect Robot Axes for Industrial Robotics | Essential Guide to Robot Types in Manufacturing and Automation”