Robotic Board Strapping Devices: Revolutionizing Packaging and Bundling

In today’s fast-paced world, where efficiency and productivity are highly valued, the need for automated solutions in various industries has become increasingly apparent. One such industry that has greatly benefited from automation is the packaging industry. With the advent of robotic board strapping devices, businesses have experienced a game-changing transformation in the way they package and bundle their products.

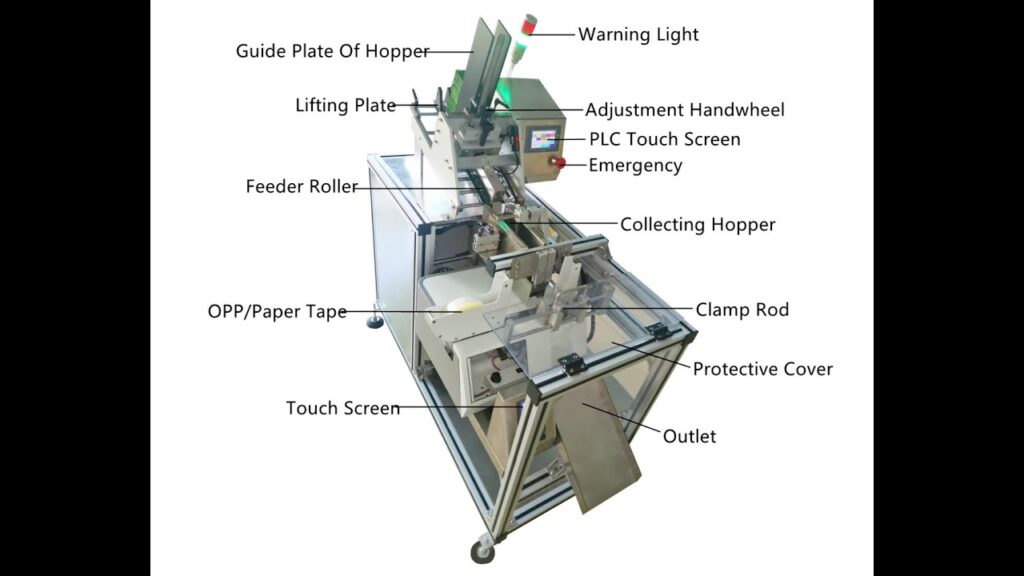

Robotic board strapping devices, also known as automatic paper tape banding bundle counting strapping machines, have revolutionized the packaging and bundling process for companies of all sizes. These advanced machines are designed to streamline the packaging workflow, reducing the time and effort required to secure and bundle items. With their sophisticated mechanisms and precision, they ensure consistency and reliability in the packaging process.

These cutting-edge machines utilize state-of-the-art technology to automate the entire strapping and bundling process. They effortlessly wrap a high-quality paper tape around items, securely holding them together for transportation or storage. The robotic arms of the machine are programmed to adapt to the shape and size of various items, making it suitable for a wide range of applications. Whether it is stacking cards, counting bundles, or strapping other materials, these machines offer unparalleled versatility.

The advantages of using robotic board strapping devices are manifold. First and foremost, they significantly enhance productivity. These machines boast impressive speeds, capable of strapping and bundling hundreds of items per minute. This level of efficiency not only saves time but also allows businesses to meet the increasing demands of the market.

Moreover, the precision and consistency offered by these machines ensure the safety and integrity of the bundled items. The robotic arms are programmed to apply the optimal amount of tension, ensuring that the straps are neither too loose nor too tight, thereby preventing damage to the products. This level of accuracy is particularly crucial in industries such as printing, where delicate paper products, cards, and documents need to be bundled and protected.

Another notable advantage of robotic board strapping devices is their ease of use. While they employ advanced technology, their user-friendly interfaces make them accessible to operators of varying technical backgrounds. The machines are equipped with intuitive controls and clear visual displays, allowing operators to quickly learn and operate them with minimal training.

Furthermore, the automated nature of these machines drastically reduces the risk of human error. Operators often face challenges when manually bundling items, such as inconsistent tensioning, misaligned strapping, or accidental damage. Robotic board strapping devices eliminate these concerns, ensuring that each bundle is perfectly secured without any variation in quality.

The impact of robotic board strapping devices is not limited to the packaging industry alone; their benefits extend across multiple sectors. With the ability to count bundles accurately and efficiently, these machines are particularly valuable in the printing industry. A large number of card manufacturers, for instance, rely on these devices to streamline their operations and ensure precise counting and bundling.

Moreover, the application of this technology in industries such as e-commerce, logistics, and manufacturing has significantly improved operational efficiency, reducing labor costs, and increasing the overall output. By automating the packaging and bundling process, businesses can allocate their human resources to more complex and strategic tasks, while leaving the repetitive and time-consuming activities to the machines.

As the demand for efficient packaging continues to grow, the future of robotic board strapping devices looks promising. Advancements in technology are likely to bring about even more sophisticated machines with enhanced capabilities. From integrated sensors for quality control to intelligent programming that adapts to various materials, the possibilities are endless.

In conclusion, robotic board strapping devices have revolutionized the packaging and bundling process, offering unparalleled efficiency, accuracy, and ease of use. These machines have proven to be indispensable for businesses seeking to optimize their packaging workflow and increase productivity. As the market evolves, their capabilities are expected to advance further, making them an essential asset for industries around the globe.

Note: This article provides a general overview of robotic board strapping devices and their benefits. For specific product recommendations or inquiries, we recommend reaching out to packaging machinery suppliers or manufacturers specializing in automated packaging solutions.

board packing machine

“Efficient Automation for Paper Tape Banding and Bundle Counting: Innovative Robotic Strapping Solutions”