Robotic arms have become a crucial component in various industries around the world. These versatile machines are capable of performing tasks that were once solely reliant on human labor. With the advancements in technology, industrial robotic arms have become more sophisticated, efficient, and cost-effective. In this article, we will explore the incredible capabilities of industrial robotic arms and how they have revolutionized the manufacturing sector.

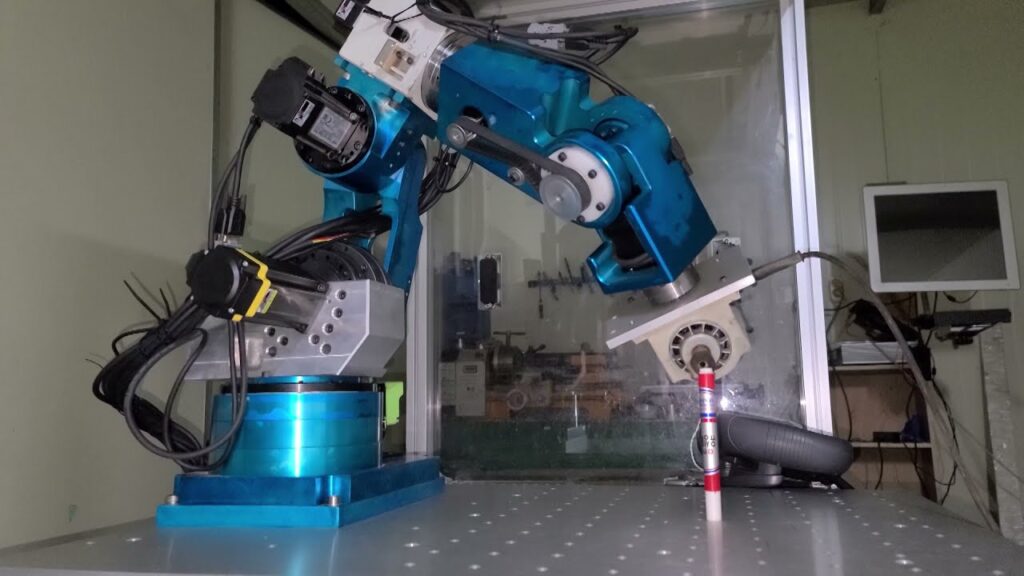

Industrial robotic arms are designed to mimic the movements of a human arm. They consist of several segments connected by joints, which allow for freedom of movement. These arms are controlled by complex algorithms and can be programmed to perform a wide range of tasks with precision and accuracy.

One of the main advantages of using an industrial robotic arm is its ability to handle repetitive tasks. These tasks, such as assembly line operations or material handling, can be monotonous and physically demanding for human workers. By delegating these tasks to a robotic arm, companies can significantly improve efficiency and reduce the risk of human errors.

Additionally, industrial robotic arms can be programmed to carry out delicate operations that require a high level of precision. For example, in the electronics industry, robotic arms are used to handle and solder tiny components on circuit boards. The level of accuracy achieved by these machines simply cannot be matched by human workers.

Another area where industrial robotic arms have made a significant impact is in dangerous or hazardous environments. These machines can be deployed in environments that are unsuitable for human workers, such as extreme temperatures or toxic fumes. This not only ensures the safety of workers but also prevents potential accidents and injuries.

Furthermore, industrial robotic arms have been instrumental in streamlining the production process. They can work at a much faster pace than humans, leading to increased productivity and reduced cycle times. By automating certain tasks, companies can optimize their workflow and meet production targets more efficiently.

One notable application of industrial robotic arms is in the automotive industry. These machines are used extensively in car manufacturing plants for tasks such as welding, painting, and assembly. The use of robotic arms has revolutionized the automotive industry, allowing for faster production rates and higher quality standards.

In recent years, there has been a growing trend of DIY robot arms. These are robotic arm kits that can be assembled and programmed by individuals at home. DIY robot arms are a great way for enthusiasts and hobbyists to explore the world of robotics and automation.

These kits typically come with all the necessary components and a user-friendly interface for programming the arm. They offer a hands-on learning experience and allow individuals to experiment with different tasks and functionalities. DIY robot arms are not only educational but also have potential practical applications in small-scale industries or personal projects.

In conclusion, industrial robotic arms have revolutionized the manufacturing sector. Their ability to handle repetitive tasks, perform precise operations, and work in dangerous environments has made them indispensable in various industries. The use of robotic arms has resulted in increased efficiency, improved safety, and enhanced productivity. Additionally, the rise of DIY robot arms has allowed for a more inclusive approach to robotics, encouraging individuals to explore and learn about automation. It is clear that industrial robotic arms are here to stay, and we can expect to see further advancements in this field in the coming years.

Industrial Robot

“Unlocking the Power of Robotic Arms: From DIY to Industrial Applications, Discover the Ultimate Arm Innovation”