Industrial Robots in Manufacturing: Revolutionizing the Heavy Operations

With the growing demand for accuracy and efficiency in heavy operations, the Articulated Robotic Arm has emerged as a game-changer in the field of industrial robots. Its high precision work and simplicity of carrying out complex tasks have made it a popular choice among manufacturers worldwide. This article explores the impact of the Articulated Robotic Arm on the manufacturing industry and its potential to revolutionize heavy operations.

Industrial robots have been used in manufacturing for several decades, but the technological advancements in recent years have taken their capabilities to a whole new level. The Articulated Robotic Arm, with its multi-joint design resembling a human arm, offers superior dexterity, flexibility, and accuracy, making it an ideal choice for performing repetitive tasks in bulk production.

One of the key advantages of the Articulated Robotic Arm is its ability to handle heavy loads effortlessly. It can lift and move objects that would be impossible for human workers due to their weight or dimensions. This capability not only enhances productivity but also ensures the safety of human workers by minimizing their exposure to hazardous environments or heavy machinery.

The simplicity of operation is another significant advantage of the Articulated Robotic Arm. With its user-friendly interface and intuitive controls, even operators with limited technical expertise can easily program and operate these robotic arms. This eliminates the need for specialized training or extensive knowledge of programming languages, making it accessible to a wider pool of users.

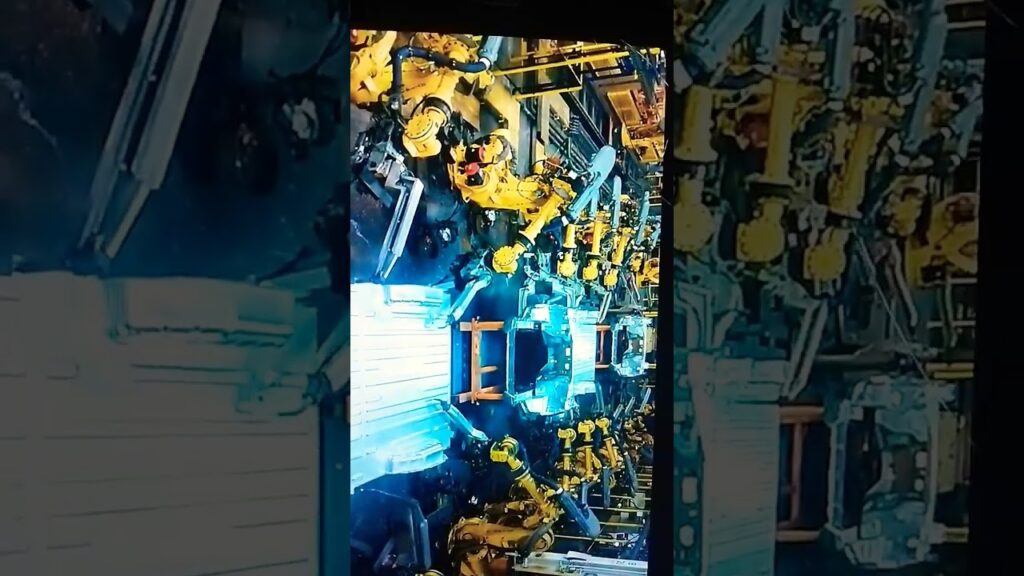

The Articulated Robotic Arm has found extensive applications in various industries, but one of its most notable applications is in car manufacturing units. The automotive industry relies heavily on robotic automation to meet the demands of bulk production efficiently. Industrial Robots 48, a renowned manufacturer, has successfully integrated these robotic arms into their car assembly lines, achieving enhanced productivity and precision.

In a car manufacturing unit, precision and speed are of utmost importance. The Articulated Robotic Arm excels at both these parameters, enabling manufacturers to streamline their production processes. With its high repeatability and accuracy, the robotic arm ensures consistent quality, reducing the chances of errors or defects in the final product. This not only improves customer satisfaction but also reduces the costs associated with rework or recalls.

Furthermore, the Articulated Robotic Arm's ability to work tirelessly without fatigue or breaks significantly increases production efficiency. Unlike human workers, these robotic arms can operate 24/7, leading to faster turnaround times and increased output. This becomes even more crucial in the era of just-in-time manufacturing, where prompt delivery is a key competitive advantage.

Moreover, the Articulated Robotic Arm offers great versatility in handling different tasks within a manufacturing unit. Its multi-joint design enables it to perform a wide range of operations, from welding and painting to material handling and assembly. This versatility allows manufacturers to optimize their production lines and adapt to changing demands without significant reconfiguration or investment.

The impact of the Articulated Robotic Arm goes beyond efficiency and productivity improvements. By automating heavy operations, manufacturers can create a safer working environment for their employees. Human workers can be reassigned to more complex and creative tasks, where their skills and expertise can be better utilized. This transition from manual labor to automation not only enhances job satisfaction but also reduces the risk of accidents or health issues associated with physically demanding tasks.

In conclusion, the Articulated Robotic Arm has emerged as a game-changer in the manufacturing industry, revolutionizing heavy operations. Its high accuracy work and simplicity of carrying out complex tasks have made it a preferred choice among manufacturers across various industries. In particular, the automotive industry has witnessed significant benefits through the integration of these robotic arms in their bulk production processes.

The Articulated Robotic Arm's ability to handle heavy loads effortlessly, coupled with its simplicity of operation, has transformed the way manufacturers approach heavy operations. It offers unparalleled precision, speed, and versatility, ensuring consistent quality and enhanced productivity. Furthermore, it has paved the way for a safer working environment by automating physically demanding tasks.

As technology continues to advance, the Articulated Robotic Arm is likely to evolve further, unlocking new possibilities for heavy operations in manufacturing. With its immense potential, we can expect industrial robots to continue shaping the future of manufacturing, revolutionizing the industry one robotic arm at a time.

Industrial Robot

"Achieving Efficient Car Manufacturing with Industrial Robots: Enhancing Bulk Production in the Manufacturing Unit"