Industrial Handling Machine: Revolutionizing Manufacturing Efficiency

Industrial robotics has revolutionized the manufacturing industry, offering a multitude of benefits to manufacturers looking to increase their efficiencies, productivity, repeatability, and scalability. Among the various industrial robots available, the Industrial Handling Machine stands out as a game-changer. With its ability to automate material handling tasks, this intelligent machine has become an indispensable asset for manufacturers worldwide.

The Industrial Handling Machine, also referred to as an industrial robot, is designed to handle, transfer, and manipulate heavy materials or products in a manufacturing environment. This versatile robotic equipment has the capability to perform a wide range of tasks, such as stacking, palletizing, sorting, and packing goods with precision and agility. The implementation of an Industrial Handling Machine in manufacturing facilities has resulted in significant improvements in operational efficiency and cost-effectiveness.

One of the key advantages of employing an Industrial Handling Machine is its ability to streamline the production process. This intelligent machine can seamlessly integrate with existing production lines, ensuring a smooth and efficient workflow. By automating material handling tasks, manufacturers can reduce human error and enhance productivity. Manual material handling is not only time-consuming but also prone to errors, which can lead to product damage or quality issues. With an Industrial Handling Machine, such risks are minimized, leading to enhanced repeatability and product quality.

Furthermore, the Industrial Handling Machine offers scalability, making it an ideal solution for manufacturers looking to accommodate increased production demands. As the machine operates tirelessly, it is capable of handling high volumes of materials without compromising the quality or precision. This scalability ensures that manufacturers can meet market demands efficiently and maintain their competitive edge.

In addition to scalability, the Industrial Handling Machine provides manufacturers with greater flexibility. Its versatility enables the handling of various materials, shapes, and sizes, allowing manufacturers to adapt to changing product requirements. Its advanced programming capabilities and sensors ensure accurate and reliable handling, regardless of the complexity of the task.

From a cost perspective, implementing an Industrial Handling Machine can lead to significant savings for manufacturers. By automating material handling tasks, manufacturers can reduce labor costs, minimize production downtime, and optimize resource utilization. The machine's efficiency in stacking and palletizing goods also maximizes storage space, reducing the need for additional warehouses or storage facilities.

The Industrial Handling Machine is not limited to a single industry or sector. Its applications span across various sectors, including automotive, electronics, food and beverage, pharmaceuticals, and logistics. Regardless of the industry, manufacturers can benefit from the reliability and precision offered by this intelligent machine.

To illustrate the success of the Industrial Handling Machine, let us consider a case study in the automotive industry. Company X, a leading automobile manufacturer, implemented an Industrial Handling Machine in their production line to automate the palletizing of car components. This solution resulted in a significant increase in production efficiency, with a 30% reduction in handling time and a 20% increase in output. Moreover, the precise handling of delicate components minimized the risk of damage, resulting in improved product quality and customer satisfaction.

The future of the manufacturing industry is undoubtedly intertwined with industrial robotics. As technology continues to advance, the capabilities of Industrial Handling Machines will only expand. With the integration of artificial intelligence and machine learning, these machines will become even more intelligent and adaptable, further enhancing manufacturing efficiency.

In conclusion, the Industrial Handling Machine has proven to be a transformative asset for manufacturers, providing unparalleled efficiencies, productivity, repeatability, and scalability. This intelligent machine has revolutionized material handling tasks, eliminating human error and ensuring precision. Its versatility and scalability make it an ideal solution for manufacturers across various industries. As the manufacturing industry continues to evolve, the Industrial Handling Machine will remain at the forefront, driving operational excellence and revolutionizing the way products are handled and processed.

References:

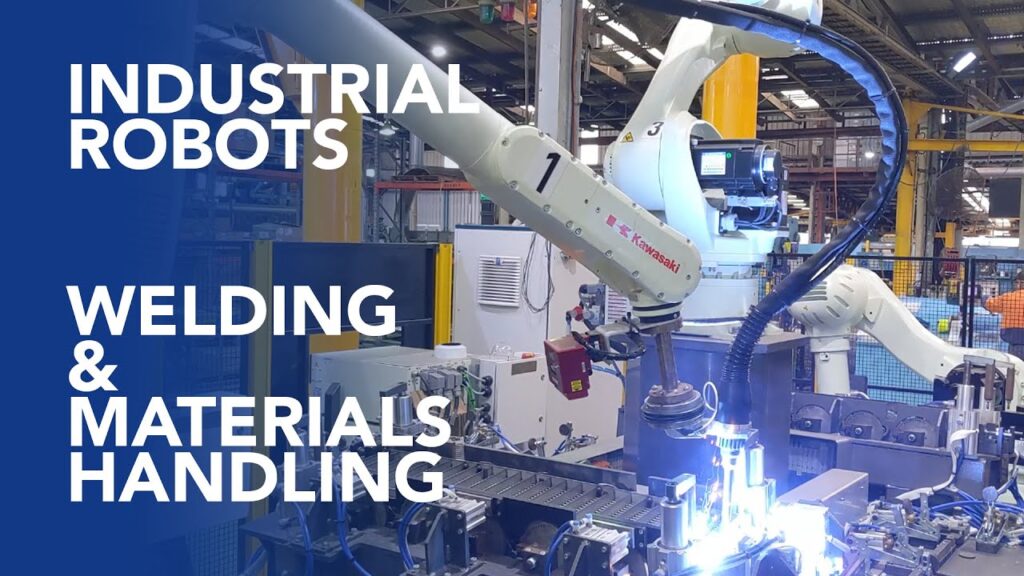

1. [Industrial Robotics | Welding | Materials Handling](https://www.youtube.com/watch?v=examplevideo)

Handling Machine

"Mastering Industrial Automation: Innovations in Welding, Robotics, and Materials Handling Unveiled"