Industrial Robots Applications: Why Industrial Robot OEMs Should Care About ROS

Industrial robots have long been a staple in factories and manufacturing plants worldwide, revolutionizing the way we produce goods and increasing efficiency on the production line. These robots are designed to perform repetitive tasks with precision and accuracy, making them invaluable in improving productivity and reducing human error. However, as technology continues to advance, the demand for even smarter and more flexible robots emerges.

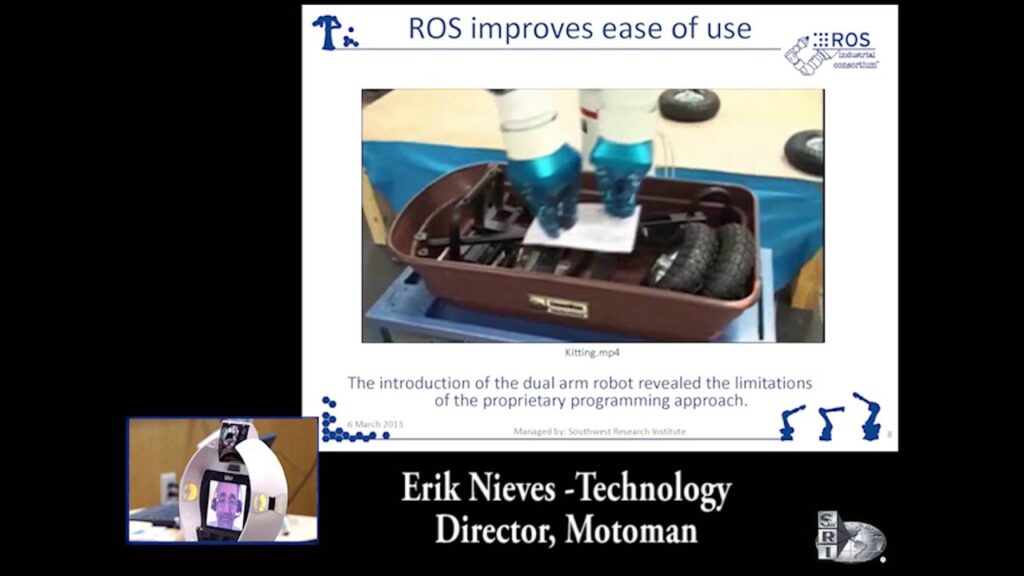

Recently, Eric Nieves, Technology Director for Yaskawa Motoman Robotics USA, delivered an insightful presentation at the ROS-Industrial Consortium Americas Annual Meeting. The focus of his speech was on the relevance of ROS (Robot Operating System) in industrial robot applications, specifically why industrial robot OEMs should care about integrating ROS into their systems.

In his presentation, Nieves highlighted the numerous advantages that ROS brings to the table. ROS is an open-source framework that provides a standardized and modular platform for developing robot software. It allows for easy integration of sensors, controllers, and algorithms, providing a seamless and consistent software environment.

One of the key benefits of ROS is its flexibility and adaptability. With a vast library of pre-built software modules, developers can quickly assemble and customize a wide range of functionalities for industrial robots. This significantly reduces development time and costs, as OEMs no longer need to start from scratch for every new application. Additionally, ROS ensures compatibility across different robot models and brands, promoting interoperability and facilitating collaboration in the robotics industry.

Industrial robot OEMs should also care about ROS because of its robust and well-established community. With over a decade of development and contributions from various researchers and engineers, ROS has become the go-to platform for robotics research and development. This vibrant community continually updates and improves the software, ensuring that it stays relevant and capable of meeting the ever-evolving needs of the industry.

The application of ROS in industrial robot OEMs’ systems opens up a world of possibilities. One notable use case is in the field of collaborative robotics, where robots work side by side with human operators. By integrating ROS, OEMs can leverage advanced perception algorithms and safety frameworks that enable robots to detect and respond to human presence, ensuring a safe and harmonious working environment. This not only improves productivity but also enhances worker safety, a crucial consideration in modern manufacturing.

Another area where ROS shines is in the integration of mobile robots within industrial environments. With ROS, OEMs can develop sophisticated navigation and mapping capabilities, allowing robots to autonomously move around factories and warehouses. By autonomously transporting materials and goods, these mobile robots streamline logistics and reduce human labor, ultimately improving overall operational efficiency.

The advantages of ROS extend beyond functionality and performance. Cost is often a significant concern for industrial robot OEMs, and here too, ROS delivers. As an open-source platform, ROS eliminates the need for expensive proprietary software licenses, enabling OEMs to reduce production costs without compromising on quality or features. Additionally, the ease of integration and development provided by ROS results in faster time to market, giving OEMs a competitive edge in the rapidly evolving robotics industry.

ROS-Industrial, a broader initiative that focuses on the industrial application of ROS, further enhances the appeal of ROS for industrial robot OEMs. The ROS-Industrial community is specifically dedicated to addressing the unique challenges and requirements of industrial automation. They provide support, training, and resources to assist OEMs in developing robust and efficient ROS-based applications for industrial settings.

In conclusion, the presentation delivered by Eric Nieves shed light on the importance of ROS in industrial robot applications and why industrial robot OEMs should care about integrating this open-source framework into their systems. The flexibility, adaptability, and compatibility offered by ROS make it an ideal platform for developing and deploying innovative robot functionalities. The well-established and active ROS community ensures that OEMs have access to a wealth of resources and support, propelling the robotics industry forward.

As industrial automation continues to transform manufacturing, it is clear that ROS is a game-changer. It empowers industrial robot OEMs to create smarter, more capable robots that can tackle a wide range of tasks, all while reducing costs and improving efficiency. Embracing ROS is not just a sensible choice; it is an essential step towards remaining competitive in the rapidly evolving world of robotics.

Industrial Robot

“The Significance of ROS in Industrial Robotics and its Applications: A Must-know for OEMs”