Title: The Revolution of Automated Packaging: Enhancing Efficiency and Precision in the Food Industry

Introduction:

In today’s fast-paced world, where efficiency and productivity are paramount, industries across various sectors are constantly seeking innovative solutions to streamline their operations. The food industry, in particular, has witnessed a remarkable transformation with the advent of automation. Embracing this revolutionary shift, Belgian customer Destrooper-Olivier recently integrated an exceptionally precise, product-friendly, and high-performance Full Automatic Packaging Line into their manufacturing process. This article delves into the remarkable capabilities of this groundbreaking technology, shedding light on how it revolutionizes the packaging process.

The Full Automatic Packaging Line: A Game-Changer in Efficiency

The Full Automatic Packaging Line, developed by Schubert, is transforming the food packaging industry in unimaginable ways. Combining state-of-the-art technological advancements with precision engineering, this innovation ensures seamless operations from start to finish.

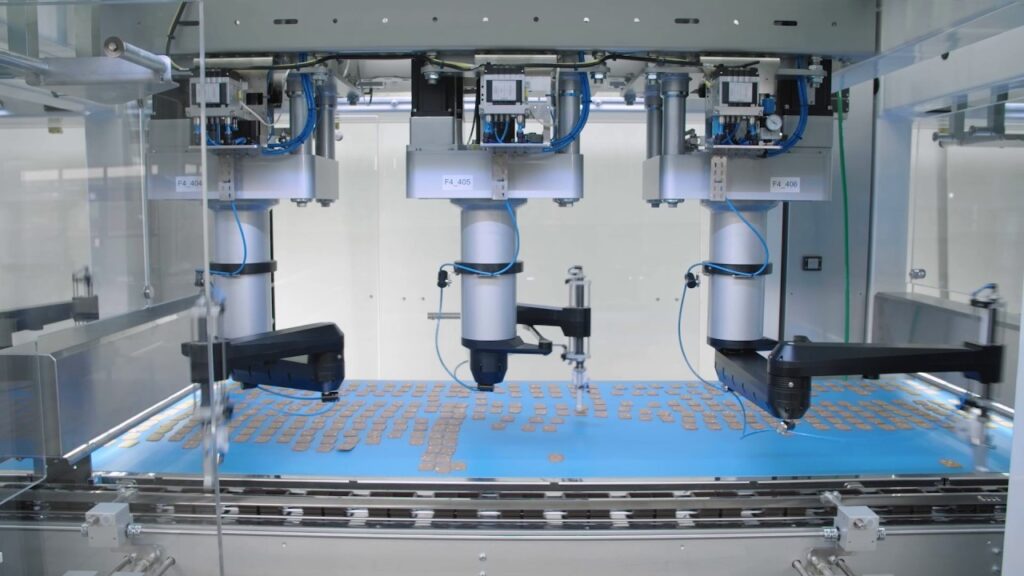

Utilizing a Pick and Place Packaging Line, the system effortlessly loads biscuits into trays, eliminating the need for manual intervention. This reduces the risk of errors while ensuring consistency in packaging, enhancing overall efficiency and productivity. The precise packaging capability of the Full Automatic Packaging Line ensures that every biscuit is perfectly positioned, enhancing presentation and customer satisfaction.

Enhancing Product Safety and Preservation:

One of the critical aspects of automated packaging lies in its ability to optimize product safety and preservation. With the Full Automatic Packaging Line, Destrooper-Olivier can ensure that their biscuits are carefully placed and sealed, guaranteeing the utmost integrity of the product. This reduces the risk of contamination or damage during transport or storage, ultimately maintaining the product’s freshness and extending its shelf life.

Product-Friendly Packaging:

The Full Automatic Packaging Line demonstrates unparalleled versatility in accommodating various product types and sizes. By utilizing advanced sensor technology, the system can detect and adapt to product variations, making it highly suitable for a broad range of packaging needs. Whether it’s delicate biscuits or robust snacks, this packaging line is capable of handling diverse product specifications without compromising quality or efficiency.

Optimized Efficiency: Streamlining Production Processes

By automating the packaging process, Destrooper-Olivier has experienced a significant reduction in production time, allowing them to meet increasing market demands effectively. The Full Automatic Packaging Line integrates seamlessly with other manufacturing units, maximizing capacity and minimizing downtime. With its swift operation, the line contributes to faster production cycles, transforming the company’s overall productivity.

Precision in Packaging: Ensuring Customer Satisfaction

In the modern business landscape, customer satisfaction stands as the cornerstone of success. The Full Automatic Packaging Line elevates the packaging process to new heights of precision and accuracy, ensuring that every customer receives biscuits of impeccable quality. The system’s ability to consistently package biscuits with precision and care enhances the overall consumer experience, leading to increased loyalty and positive brand reputation.

Environmental Considerations: Sustainability in Automation

In addition to its numerous benefits, the Full Automatic Packaging Line also contributes to a more sustainable future. With reduced packaging material waste and optimized energy consumption, this automated system aligns with Destrooper-Olivier’s commitment to environmental responsibility. By leveraging advanced technology, businesses can cultivate sustainability alongside operational efficiency.

Conclusion:

The integration of the Full Automatic Packaging Line from Schubert has brought about a paradigm shift in the food packaging industry. Destrooper-Olivier’s decision to embrace automation showcases their dedication to staying at the forefront of innovation. With enhanced precision, efficiency, and product-friendly packaging, this cutting-edge technology has improved the overall quality of the company’s biscuits. As the food industry continues to evolve, it is imperative that businesses recognize the immense potential of automated packaging to revolutionize their operations and cater to the ever-growing consumer demands.

Automatic Packing Line

“Efficient and Automated Biscuit Packaging Process Revealed: Watch as Schubert Pick and Place System Expertly Loads Trays”