AUTOMATIC WIRE PACKING LINE

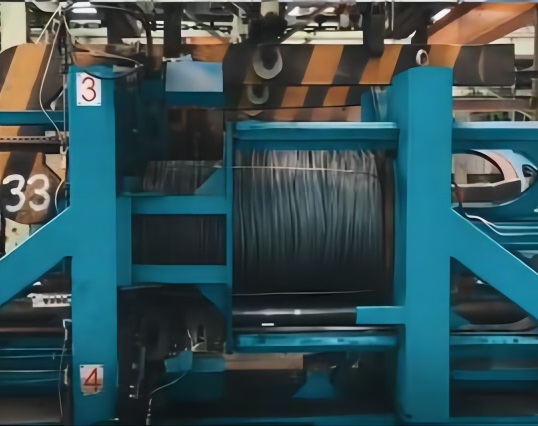

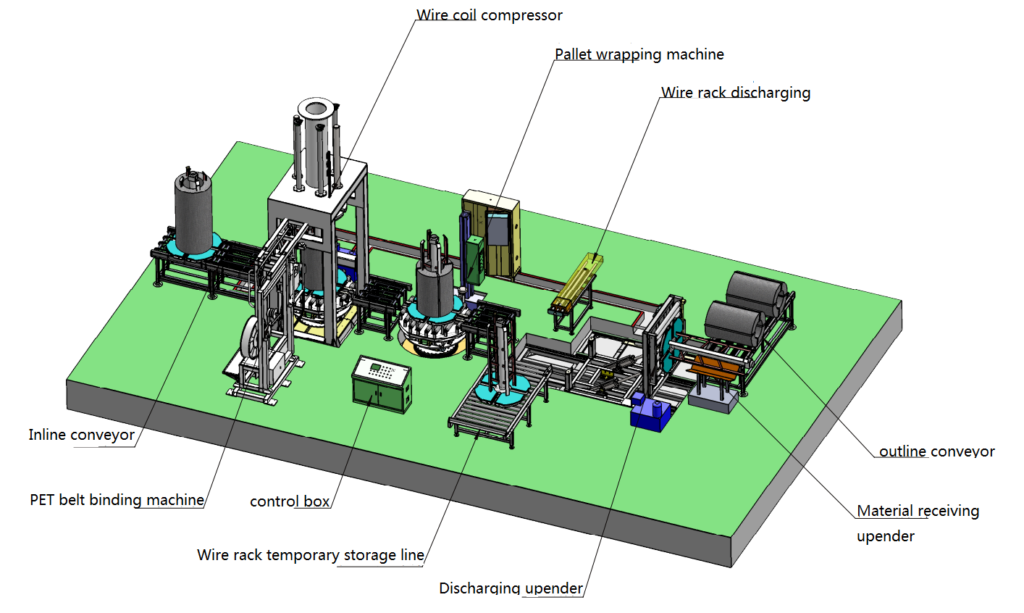

FHOPE offers an automatic wire packing line that incorporates a wire coil compactor and a strapping machine for efficient online handling of wire coils with baskets.

The wire coil packing line features an Automatic Strapping Machine that executes strappings at various positions. The wire coil, along with the basket, is placed on a table where the compactor system compacts the wire coil on the spool. This process is repeated to ensure complete compaction. The system is fully adjustable with inverters to accommodate different materials, making it a highly efficient solution for enhancing your wire coil packaging. This setup meets the demands for higher packaging efficiency, requiring minimal space and reducing labor costs associated with wire handling.

Operators are to position a basket with its wire coil on the conveyor, which then transports the coil to the compacting station. This automatic process seamlessly integrates compression with the drawing machine to manage the basket effectively, ensuring the wire coil is securely gathered. Utilizing this automatic line significantly boosts production while cutting down on labor expenses.

Automatic Wire Packing Line

WHAT THE WIRE PACKING LINE BENEFITS TO?

The design of the Wire Coils Packing Line is expertly crafted to meet your needs for maximum high-speed packaging. An automatic solution is seamlessly implemented to facilitate an unmanned operation without any gaps.

Wire Coils Packaging Lines Technical Factors:

- The machine will be configured to accommodate different sizes, weights, and types of packaging materials.

- The layout of the packaging line will be planned based on your resource utilization and the available space in your factory.

- Our after-service encompasses installation, certification, and training, all provided by our skilled engineer.

- A wide range of packaging materials is available to ensure attractive and effective packaging.

Benefits of Wire Coil packing Line:

- Enhanced productivity in handling, packaging, and palletizing suitable for a variety of coil specifications.

- Fully accountable throughout all processes, with seamless integration into the ERP system from packaging to inventory management.

- Improved packaging quality, including coil surface protection, strapping, and efficient palletizing.

- Safe operations designed to minimize the risk of operator injuries.