Title: Advanced Nesting for Coil Slitting Line and Laser Coil Using STEP, DXF, DWG, PDF, and CSV

Description:

Introduction:

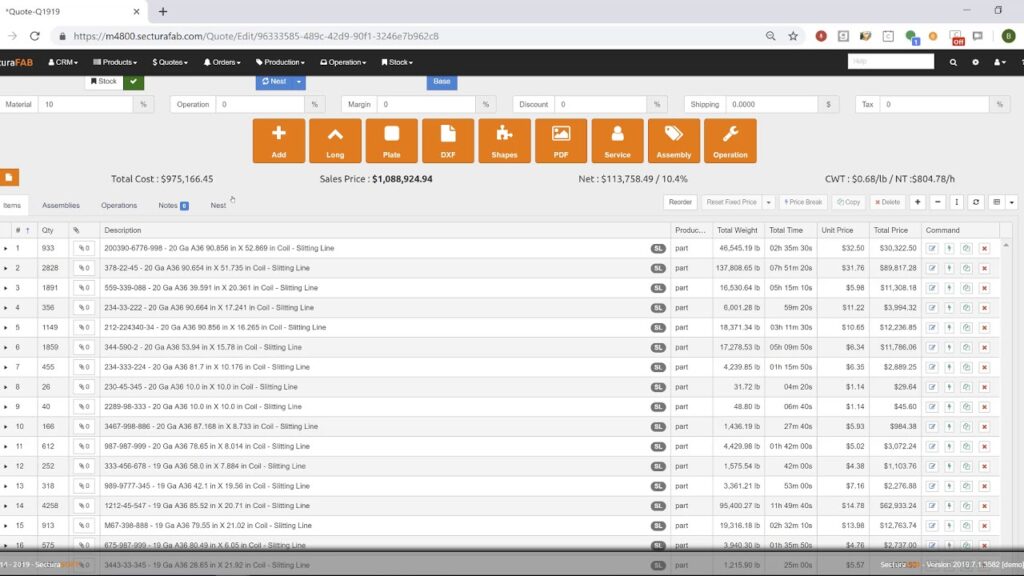

This video showcases the advanced nesting process for coil slitting line and laser coil by utilizing various file formats such as STEP, DXF, DWG, PDF, and CSV. The efficient nesting process results in minimum scrap, maximum yield, and cost-saving benefits.

Video Content:

The video provides a step-by-step process for advanced nesting where multiple coils are placed on a single line without overlapping. This nesting methodology is based on advanced algorithms that can optimize the placement of parts, reduce material usage, and increase productivity.

The video also shows how this nesting process can optimize the production of various parts, including simple and complex parts. The nesting system is designed to work with a range of shapes and sizes and can be adjusted to cater to the specific requirements of each part.

In addition, the video highlights the benefits of using various file formats such as STEP, DXF, DWG, PDF, and CSV. These file formats allow for seamless integration with a range of software programs, providing an easy and efficient way to transfer data between systems.

Conclusion:

By using advanced nesting techniques, coil slitting line and laser coil manufacturers can optimize their production processes, reduce waste and costs, and increase productivity. This video provides a valuable insight into how various file formats such as STEP, DXF, DWG, PDF, and CSV can be used to enhance the nesting process and help achieve these goals.

Hashtags: #coils #advancednesting #coilslittingline #lasers #productivity #efficiency #fileformats #STEP #DXF #DWG #PDF #CSV

Keywords/Tags: coil slitting line and laser coil, advanced nesting, file formats, STEP, DXF, DWG, PDF, CSV, productivity, efficiency, scrap reduction, cost-saving, part optimization, software integration.