Title: Coil Fed Laser Blanking Line for the Production of Finished Clean Laser Cut Parts | Fagor Arrasate

Description:

Introduction:

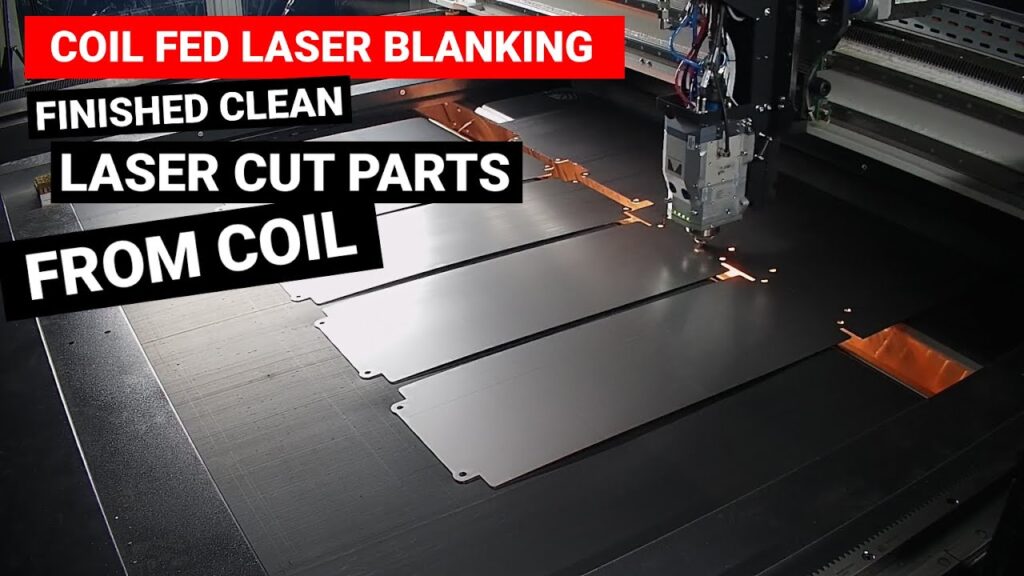

This video showcases the impressive capabilities of Fagor Arrasate’s Coil Fed Laser Blanking Line, a revolutionary technology that allows for the production of finished clean laser cut parts that are ready for use straight from the machine.

Video Content:

In this video, viewers will see the Coil Fed Laser Blanking Line in action as it expertly cuts and processes a range of materials, including steel and aluminum. This highly sophisticated technology includes features such as automatic coil loading, unloading, and stacking, as well as advanced laser cutting capabilities that ensure maximum precision and efficiency.

The line’s built-in quality control system ensures that parts are cut perfectly every time, eliminating the need for additional tooling or adjustments. Furthermore, the machine’s compact design and low energy consumption make it an incredibly versatile and eco-friendly solution for a range of manufacturing applications.

With the Coil Fed Laser Blanking Line, manufacturers can save time, reduce costs, and increase production without sacrificing quality. Whether you are in the automotive, HVAC, or general engineering industries, this technology offers a new standard in precision and productivity.

Tags and Keywords:

– Coil fed laser blanking line

– Laser cut parts

– Fagor Arrasate

– Precision manufacturing

– Steel processing

– Aluminum cutting

– Quality control

– Automated production

– Eco-friendly manufacturing

– Advanced cutting technology

Hashtags:

#coilfedlaserblankingline #lasercutparts #fagorarrasate #precisionmanufacturing #steelprocessing #aluminumcutting #qualitycontrol #automatedproduction #ecofriendlymanufacturing #advancedcuttingtechnology