Title: Slitting Line / Längsteilanlage / Coil to Coil Slitter / Hasító-Felcsévélő Sor – Overview and Importance in Metal Industry

Introduction:

Slitting Lines or Coil to Coil slitters, also known as Längsteilanlage or Hasító-Felcsévélő sor, holds a significant place in the metal industry. These are machines that help in cutting large coils of metal into narrower coils with specific widths. The process includes unwinding the metal coil and moving it through several sets of rotary blades that cut it into multiple coils. This article discusses the importance and overview of Slitting Lines in the metal industry.

Video Content:

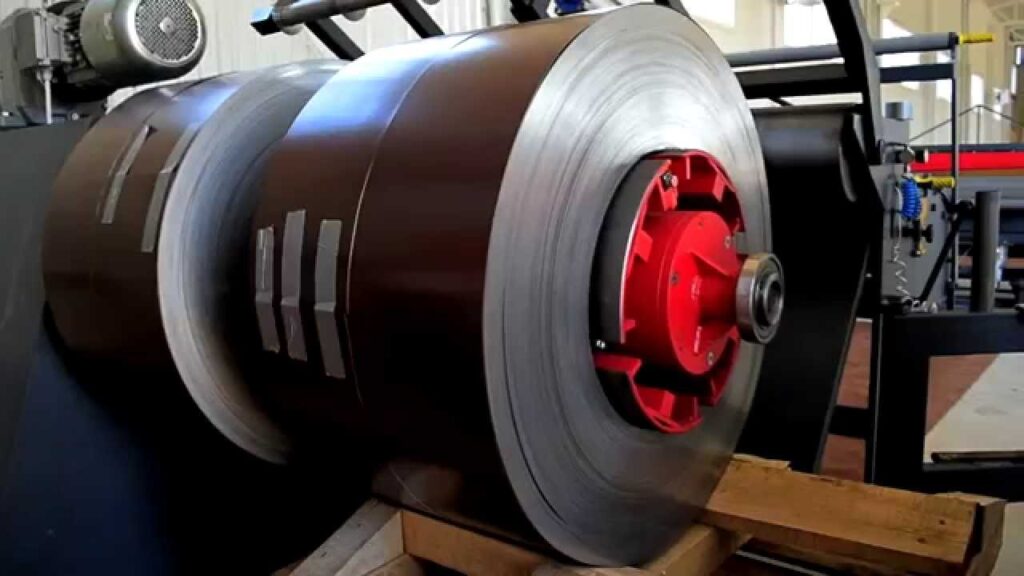

The video features a Slitting Line or Längsteilanlage or Coil to Coil slitter that is used in the metal industry for cutting large coils of metal into smaller coils with desired widths. The video demonstrates the working of the machine and its components, including uncoiler, scrap winder, and tension stand. It highlights the significance of the machine in the metal industry, making it possible to produce metal sheets as per the requirement of the customer.

Slitting Lines or Längsteilanlage or Coil to Coil slitters are a crucial part of the metal processing industry, helping to produce metal sheets for various applications, such as roofing, construction, automotive, and many others. These machines are versatile and can handle various metal types, such as aluminum, copper, brass, and steel.

The video explains how the machine works by unwinding the coil and passing it through rotary blades that cut the metal into narrow coils with desired widths. The machine has various components such as an uncoiler, scrap winder, and tension stand that work together to ensure a precise and accurate cut.

The video also features several benefits of using slitting lines, such as improved efficiency, lower production costs, faster turnaround times, and reduced waste. Using a slitting line or Coil to Coil slitter eliminates the need for manual processing and reduces the risk of human error.

Conclusion:

Slitting Lines or Längsteilanlage or Coil to Coil slitters have revolutionized the metal processing industry by making the process of cutting and slitting coils more efficient and accurate. The video highlights the importance of these machines and their significant contribution to the metal industry. By incorporating the use of digital technology, these machines have become an essential tool for the metal processing industry and will continue to play a vital role in the future.

Keywords: Slitting Line, Längsteilanlage, Coil to Coil Slitter, Hasító-Felcsévélő Sor, metal industry, rotary blades, uncoiler, scrap winder, tension stand, metal sheets, roofing, construction, automotive, efficiency, production costs, waste reduction, precision.

Tags: metal processing, machine, rotary blades, cutting, coil, metal sheets, manufacturing, roofing, automotive, precision, scrap winder, tension stand, cost-effective.

Hashtags: #SlittingLine #Längsteilanlage #CoiltoCoilSlitter #HasítóFelcsévélőSor #MetalProcessing #MetalCutting #Efficient #Precision #QualityControl #Manufacturing.