Title: Inline Palettenwender – Inverter Inline: Efficient Machine for Line-Driven Pallet Inversion

Description:

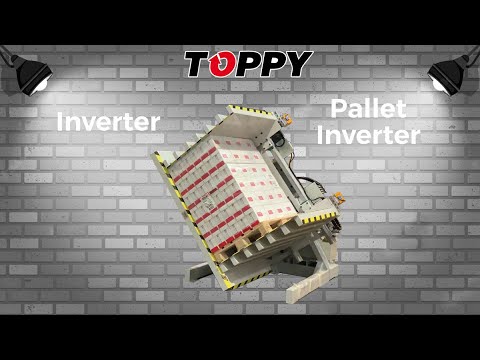

In this video, we are thrilled to introduce you to the Toppy Inverter Inline – a revolutionary machine for pallet inverting in line. The Inverter Inline works by flipping over the pallets while they are still in motion, which saves time and reduces labor costs. With its advanced features, this machine allows companies to keep up with high-volume production demands and streamline their workflows.

Introduction:

The Toppy Inverter Inline is a cutting-edge machine designed for businesses that require an efficient solution for pallet inversion. This machine offers a range of benefits that will make a positive impact on any company’s operations.

Video Content:

In this video, you will see the Toppy Inverter Inline in action and learn about its key features. This includes its ability to handle pallets of various sizes and weights, as well as its automated operation mode. Another exciting feature of the Inverter Inline is its safety features, which prevent accidents and ensure the safety of the operators.

Our team of technical engineers has spent countless hours perfecting the design of the Inverter Inline to ensure its optimal performance and reliability. The machine is easy to operate and maintain, making it an ideal solution for businesses of any size.

Additional Tags and Keywords:

Keywords: Inline Palettenwender, Inverter Inline, line-driven pallet inversion, automated operation mode, safety features, efficient machine, fast-paced production.

Hashtags: #InverterInline #ToppyInverter #Palettenwender

In conclusion, the Toppy Inverter Inline is a state-of-the-art solution that offers a range of benefits to businesses looking for an efficient pallet inversion machine. With its advanced features and safety measures, the Inverter Inline is a must-have for any company that wants to optimize its production processes.