Pallet changer – TOPPY MASTER INVERTER: A Fully Automated Logistic System

Introduction:

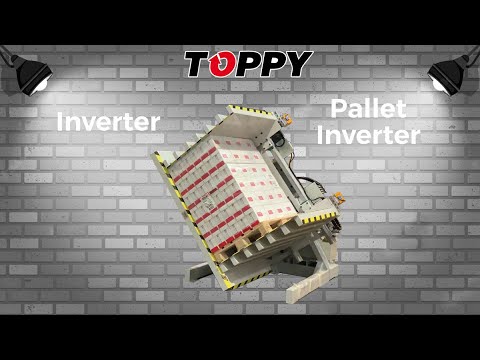

In this video, you will witness a revolutionary, fully automated logistic system consisting of a Toppy Master Inverter pallet changer. The system replaces pallets without tilting or damaging the load, ensuring safe and effective transport of goods.

Video Content:

The Toppy Master Inverter is the ultimate solution for pallet changing needs in industries such as food, pharmaceuticals, and logistics. The fully automated system eliminates the need for manual intervention in pallet replacement, increasing efficiency and productivity.

The system operates at a rate of up to 25 pallets per hour, ensuring fast and uninterrupted material flow. It can handle loads up to 2000 kg and can accommodate various pallet sizes and types. The Toppy Master Inverter also has an intuitive control panel for easy monitoring and operation.

With its compact design, the Toppy Master Inverter requires minimal space and can be easily integrated into existing logistics systems. The system also eliminates the need for manual labor, reducing workplace fatigue and injuries.

Conclusion:

The Toppy Master Inverter pallet changer is a game-changer in the logistics industry. Its fully automated features ensure fast and safe pallet changing, reducing manual labor and increasing productivity. With its compact design and intuitive controls, the system is a must-have for any industry that values efficiency and safety.

Additional Tags and Keywords:

Pallet changing system, Automated warehouse logistics, Material handling equipment, Industrial automation, Warehouse automation

Hashtags:

#PalletChanger #ToppyMasterInverter #AutomatedLogistics #MaterialHandling #WarehouseAutomation