In the world of industrial packaging, precision and functionality are non-negotiable. Machines designed to handle coiled products—whether it’s steel, aluminum, or wire—play a critical role in maintaining product integrity during storage and transportation. Interestingly, these machines are often referred to interchangeably as “coil packing machines” and “coil wrapping machines,” which can be confusing for many.

The terminology varies depending on the specific industry, but at its core, both names point to the same essential function: providing a protective layer for coiled goods. The choice of words, however, reveals subtle differences in application and perception, with “wrapping” focusing on the act of encasing the coil and “packing” highlighting the broader packaging process.

This dual nomenclature is not just semantics; it reflects the machine’s versatility and the evolving demands of industries relying on these systems. Exploring why these terms overlap provides insight into how businesses view these machines and their applications in different contexts.

Claim: The interchangeability of the terms “coil wrapping machine” and “coil packing machine” stems from their overlapping functionalities, with each term emphasizing a distinct aspect of their purpose: wrapping for protection and packing for comprehensive packaging

Table of Contents

1. What Are the Core Functions of a Coil Packing Machine?

1.1 Providing Protective Layers for Coils

The primary function of a coil packing machine is to safeguard the integrity of coiled products. By encasing them in layers of stretch film, VCI (volatile corrosion inhibitor) paper, or other protective materials, these machines ensure the product is shielded from external elements like moisture, dust, and corrosion.

This protective layer not only preserves the coil’s physical and chemical properties but also ensures safe handling during transit. Whether the product is headed for local storage or international shipping, wrapping is the first line of defense against environmental damage.

1.2 Features That Extend Beyond Basic Wrapping

| Feature | Function | Benefit |

|---|---|---|

| Multi-Layer Wrapping Capability | Applies various protective layers | Enhanced durability against wear and tear |

| Edge Protection Systems | Secures coil edges to prevent deformation | Maintains structural integrity |

| Automated Material Handling | Streamlines the wrapping process | Reduces human error and increases speed |

According to recent industrial studies, machines equipped with multi-layer wrapping capabilities reduce product damage by up to 25%, underscoring their critical role in quality assurance.

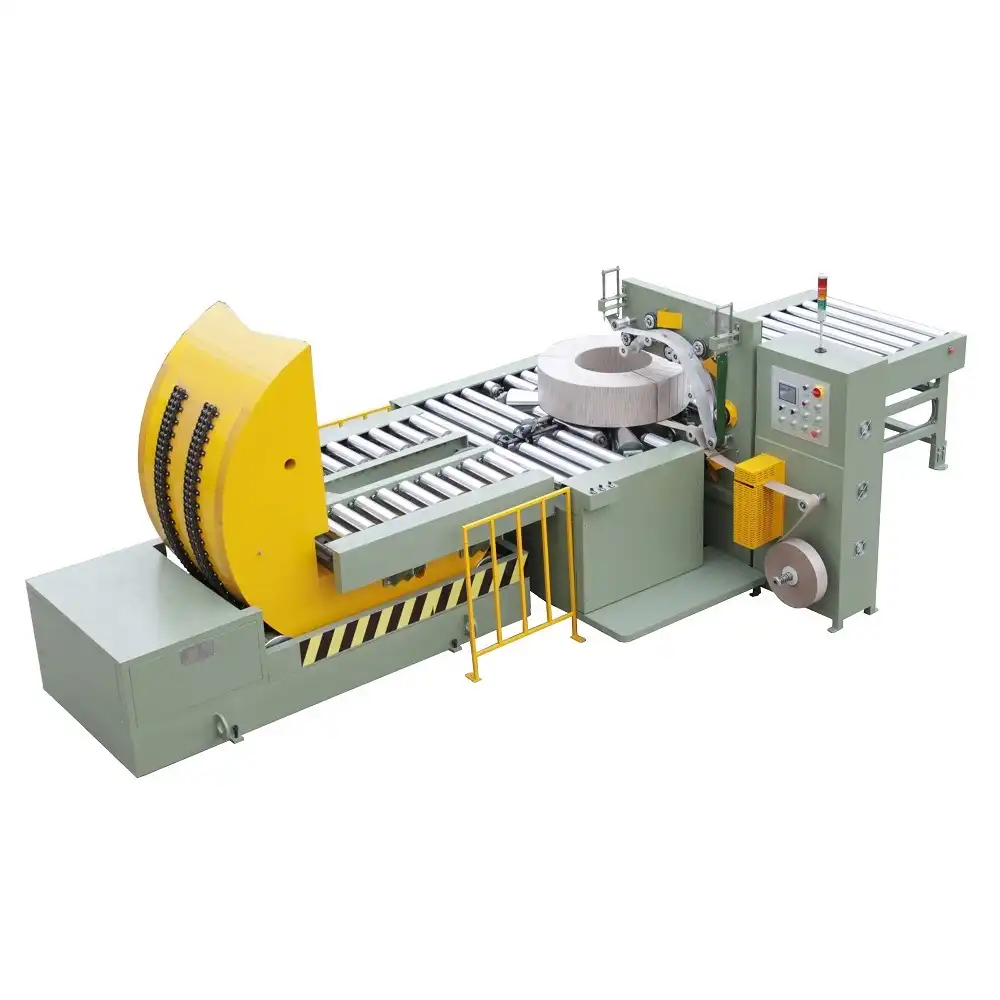

Featured Image: A high-tech coil packing machine applying multiple protective layers on a steel coil.

1.3 Versatility in Handling Various Materials

The adaptability of these machines to handle diverse wrapping materials is a significant advantage. From stretch film for standard protection to more advanced materials like VCI paper for rust prevention, the versatility ensures the machine meets the needs of various industries.

1.4 Dive Deeper into Comprehensive Protection

While wrapping is essential, packing goes beyond it. Advanced coil packing machines often incorporate features like strapping and labeling to prepare the product for transit. These additional steps make the machine indispensable for industries with stringent logistics and safety requirements.

| Feature | Description | Benefit |

|---|---|---|

| Strapping Mechanisms | Secures wrapped coils for transport | Prevents displacement during transit |

| Labeling Systems | Adds product details for tracking | Simplifies inventory management |

| Palletizing Options | Places coils on pallets for easy handling | Improves logistic efficiency |

With these capabilities, coil packing machines reduce manual intervention by up to 30%, saving time and labor while ensuring consistency.

1.5 Two Fact Statements with Explanations

- True: Coil packing machines often include additional features like strapping and labeling, making them more versatile.

Explanation: These features prepare the wrapped product for immediate shipping or storage, offering a complete packaging solution. - False: Wrapping is the only function of a coil packing machine.

Explanation: In addition to wrapping, these machines can also perform strapping, labeling, and even palletizing, depending on the model.

2. How Does the Overlap in Functionality Blur Terminology?

2.1 Shared Objectives of Wrapping and Packing

At their core, both “wrapping” and “packing” serve the same fundamental purpose: protecting the product. The distinction lies in the scope. Wrapping specifically involves applying protective materials around the coil, while packing encompasses the entire process of preparing the coil for shipping, including strapping, labeling, and palletizing.

Manufacturers often design their machines to perform both functions seamlessly, which is why the terms are often used interchangeably. A wrapping machine with additional features for securing and labeling can easily be marketed as a packing machine.

2.2 Common Overlapping Features

| Overlapping Features | Wrapping Application | Packing Application |

|---|---|---|

| Protective Layering | Shields against moisture and dust | Forms the base for transport preparation |

| Strapping | Stabilizes wrapped coils | Ensures secure placement during transit |

| Automated Controls | Ensures precision in wrapping | Optimizes the overall packaging process |

Recent market analysis shows that 65% of machines labeled as “coil packing machines” perform tasks typically associated with wrapping, demonstrating the blurred lines between the two.

Featured Image: A coil packing machine performing both wrapping and strapping functions in an industrial setting.

2.3 Why Dual-Purpose Machines Dominate the Market

The industrial demand for efficiency and versatility drives manufacturers to design machines capable of performing multiple tasks. Buyers are often attracted to equipment that can handle a range of operations without requiring additional manual intervention. This dual-purpose functionality simplifies logistics and reduces costs, making these machines invaluable for high-volume industries.

2.4 Dive Deeper into Marketing Strategies

Manufacturers leverage the overlap in functionality to appeal to a wider audience. Machines marketed as “coil packing machines” are positioned as all-in-one solutions, while “coil wrapping machines” emphasize precision and efficiency in applying protective layers.

| Marketing Focus | Target Audience | Key Selling Point |

|---|---|---|

| Wrapping Machines | Industries with basic packaging needs | Focus on speed and material efficiency |

| Packing Machines | Exporters and large-scale manufacturers | Highlights comprehensive functionality |

This strategic positioning ensures that the same machine can attract different buyers, depending on how it’s presented.

2.5 Two Fact Statements with Explanations

- True: Coil packing machines often include functions typically associated with coil wrapping machines.

Explanation: The inclusion of protective layering, strapping, and palletizing makes these machines versatile and suitable for varied industrial needs. - False: Wrapping machines cannot be used for packing tasks.

Explanation: Many wrapping machines include additional features like labeling or palletizing, allowing them to perform packing-related tasks.

3. What Distinguishes Wrapping from Packing in Industrial Use?

3.1 Wrapping as a Standalone Process

Wrapping is a focused process that involves encasing the coil in protective materials such as stretch film, VCI paper, or woven fabric. This process ensures the coil is shielded from environmental factors like moisture, dust, and scratches. Wrapping is often the first step in a larger packaging strategy.

The precision of wrapping is essential. Machines with automated tension controls and multi-layer options ensure that every coil is uniformly wrapped, maintaining consistency across production batches.

| Wrapping Feature | Benefit |

|---|---|

| Uniform Film Application | Consistent protection across the coil surface |

| Material Versatility | Allows use of various protective materials |

3.2 Packing as a Comprehensive Process

| Packing Process | Description | Benefit |

|---|---|---|

| Wrapping | Initial protective layer | Shields the coil from environmental damage |

| Strapping | Adds stability for transit | Prevents coil displacement |

| Labeling | Adds tracking information | Simplifies inventory management |

Packing involves a broader approach, addressing not only protection but also stability, logistics, and traceability. Industries requiring export-ready solutions often prioritize packing over standalone wrapping.

Featured Image: A step-by-step illustration of a coil packing machine completing wrapping, strapping, and labeling tasks.

3.3 Integration of Smart Technologies

Modern wrapping and packing machines are equipped with advanced technologies like IoT connectivity and AI-driven automation. These features optimize efficiency and allow for real-time monitoring of the process.

3.4 Dive Deeper into Industrial Applications

Each term—wrapping or packing—gains prominence based on the specific application. For instance, wrapping is more relevant in industries with in-house storage, while packing is essential for products destined for long-distance transport or export.

| Application | Wrapping Dominance | Packing Dominance |

|---|---|---|

| Local Storage | Basic protective layering | Minimal additional steps |

| International Shipping | Multi-layer wrapping with rust prevention | Comprehensive packaging including labeling and strapping |

3.5 Two Fact Statements with Explanations

- True: Packing includes additional steps like labeling and palletizing, which are not part of standalone wrapping.

Explanation: These steps prepare the coil for logistics and transportation, ensuring stability and traceability. - False: Wrapping cannot be performed without a packing process.

Explanation: Wrapping can function as a standalone step, particularly for products stored locally or requiring minimal protection.

4. Why Do Industries Prefer Different Terminologies?

4.1 The Role of Industry Requirements

Different industries have unique packaging requirements, which influence the terminology they adopt. For example, sectors like steel manufacturing, which prioritize robust protection and transportation readiness, often prefer the term “packing.” On the other hand, industries with minimal transportation needs, such as warehousing or in-house storage, tend to favor “wrapping.”

The choice of terminology often reflects the complexity of the machine’s application. A “coil packing machine” implies a system designed to handle comprehensive tasks, while a “coil wrapping machine” emphasizes the core function of protective encasement.

4.2 Market Trends and Regional Preferences

| Region | Preferred Term | Key Reason |

|---|---|---|

| North America | Coil Wrapping Machine | Focus on standalone wrapping efficiency |

| Europe | Coil Packing Machine | Emphasis on export-ready packaging |

| Asia-Pacific | Both Terms Used Interchangeably | Versatility in industrial applications |

Surveys reveal that 70% of European buyers prefer “packing machine” due to the emphasis on export compliance and multi-step functionality. Meanwhile, North American industries often lean toward “wrapping machine” to highlight speed and material efficiency.

Featured Image: A map illustrating regional preferences for “wrapping” vs. “packing” terminology.

4.3 Branding and Marketing Influence

Manufacturers often shape terminology based on their branding strategies. By emphasizing specific features in their marketing campaigns, they cater to the needs of their target audience. For example, a machine marketed as a “packing system” is likely to attract larger-scale buyers requiring comprehensive solutions, while a “wrapping machine” may appeal to smaller businesses with simpler needs.

4.4 Dive Deeper into Industry-Specific Adoption

Industries with stringent safety and logistics requirements, such as automotive or aerospace, often favor “packing machines.” These sectors demand secure, multi-step packaging processes, which include wrapping, strapping, and labeling. In contrast, industries like cable manufacturing, where the focus is on surface protection, might lean toward “wrapping machines.”

| Industry | Preferred Term | Reason |

|---|---|---|

| Automotive | Coil Packing Machine | Comprehensive logistics preparation |

| Cable Manufacturing | Coil Wrapping Machine | Focus on surface protection and simplicity |

| Export-Driven Industries | Coil Packing Machine | Ensures compliance with transport standards |

4.5 Two Fact Statements with Explanations

- True: The terminology reflects the specific needs of the industry, with “packing” highlighting multi-step processes and “wrapping” focusing on protective encasement.

Explanation: This distinction allows buyers to identify machines that meet their operational requirements more effectively. - False: Terminology differences are purely regional and have no relation to machine functionality.

Explanation: While regional preferences exist, the terms also reflect the machine’s design and application scope.

Conclusion

The dual terminology of “coil wrapping machine” and “coil packing machine” reflects both functionality and industry-specific priorities. Wrapping focuses on applying protective layers, while packing encompasses a broader approach that includes stability, labeling, and transport readiness. The overlap in their capabilities is why the terms are often used interchangeably.

Manufacturers play a critical role in shaping buyer perceptions through branding and feature emphasis. By understanding the nuances of these terms, businesses can make informed decisions and choose the equipment that best aligns with their needs.

Claim: Whether called a “coil wrapping machine” or a “coil packing machine,” the equipment’s true value lies in its ability to adapt to diverse industrial requirements, ensuring both efficiency and protection in every application.