Fhope has developed the Inline Pallet Changer, a high-speed automated system designed for the efficient replacement of wooden pallets with plastic or aluminum ones during high-volume production processes. This system integrates advanced technology to streamline pallet handling and ensure seamless operations.

Key Features and Components

- Versatile Handling Options: The system allows for the automatic replacement of wooden pallets with alternatives like plastic or aluminum, accommodating various industry needs.

- High-Speed Operation: Capable of handling up to 40 pallets per hour, based on a standard pallet size of L1200 x W1200 x H80-1800mm.

- Integrated Control System: Includes IoT capabilities for real-time information sharing with management systems, facilitating digital recording and monitoring throughout the pallet handling process.

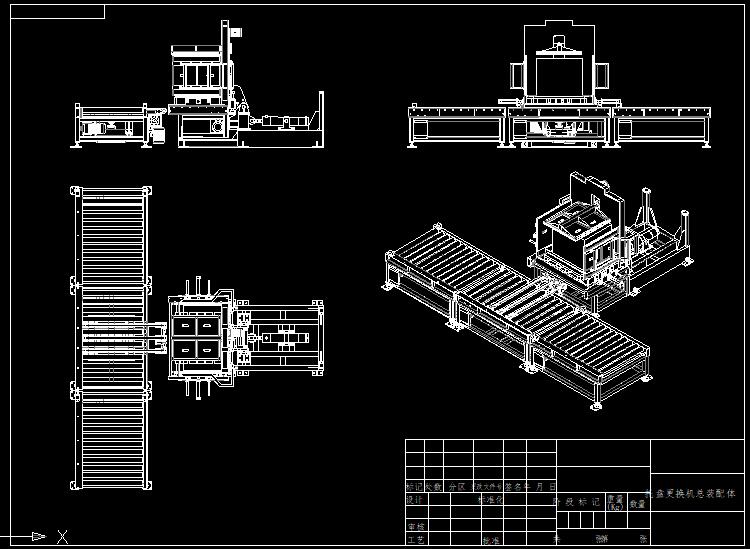

System Configuration

- In & Out Feeding: Equipped with roller conveyors for efficient in and out feeding.

- 90-Degree Transfer Table: Features a working table that facilitates 90-degree transfers, optimizing space and handling.

- Hydraulic Drive System: Utilizes a hydraulic system for upending and lifting devices, ensuring robust and reliable operation.

Automation and Safety

- Enhanced Automation: Additional automation devices can be integrated, such as an automatic pallet in-feeding device, automatic pallet stacking machine, and automatic pallet wrapping machine.

- Fully Automated Operation: The system supports a completely unmanned operation, including:

- Loading from a pre-stream line (e.g., another conveyor or forklifter).

- Automatic pallet in-feeding.

- Automatic pallet changing.

- Automated stacking and recycling of changed pallets.

- Automatic pallet out-feeding.