Features:

- It incorporates a user-friendly interface using PLC and HMI controls for ease of operation.

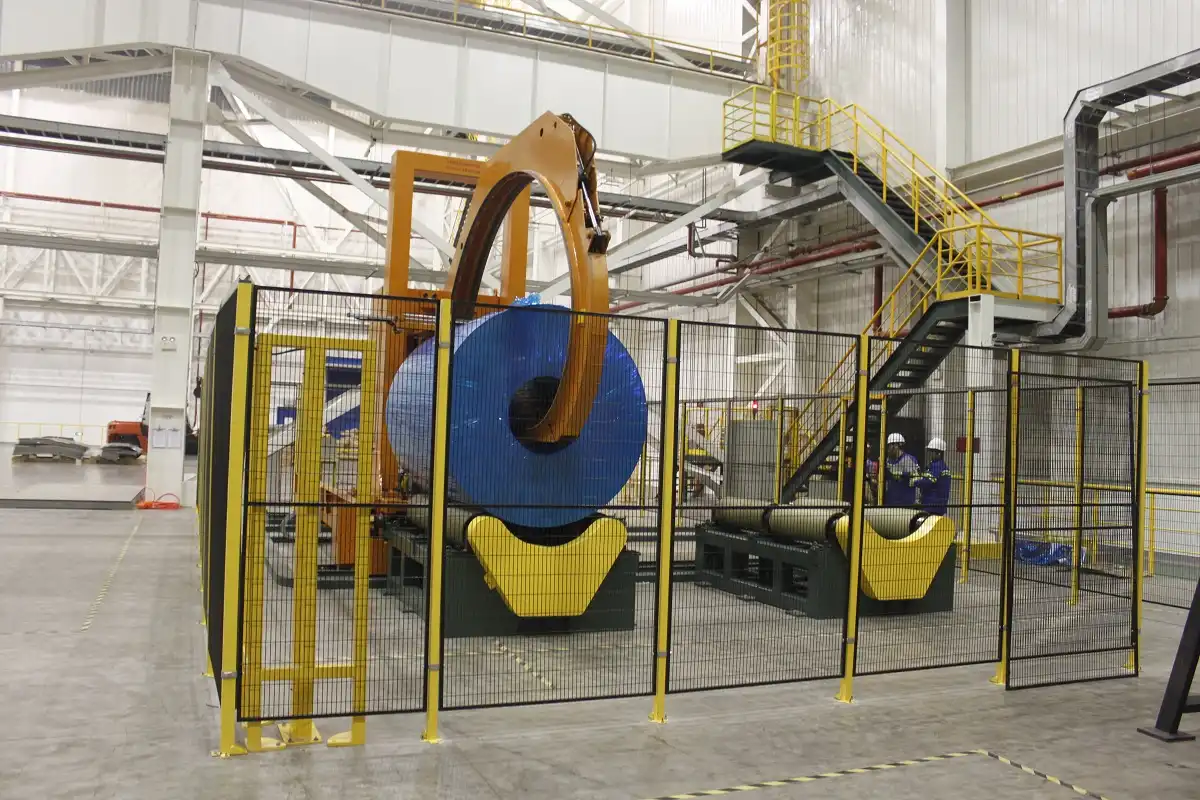

- Features an orbital wrapping system specifically tailored for secure packaging.

- Includes two shutters that cross the internal diameter of the coil during packing for comprehensive coverage.

- The wrapping machine automatically adjusts its position to the right or left to optimize the packaging process.

- Operators can select between manual and automatic modes, depending on the task requirements.

- A converter is utilized to fine-tune the overlap of the packing tape based on specific needs.

- Inputting the outer diameter (OD), inner diameter (ID), width, and correction parameters of the coiled metal simplifies operations; other settings are automatically adjusted.

- The height of the turning ring can be motor-adjusted to align with different coil diameters for centered positioning.

- Includes a function to reset the wrapping position to its starting point.

- Equipped with sensors for precise trolley positioning.

- Safety features include guardrails and a soft start and stop mechanism.

- Offers dual-layer wrapping with both stretch film and opaque film for enhanced protection.

- The packaging tension is adjustable to accommodate various requirements.

- Features an automatic material cutting and feeding system for streamlined operation.

- The machine is fitted with an indicator alarm that notifies operators immediately if any issues arise, with the specific problem displayed on the interface.

- A special brake on the tape release device prevents the material from folding, ensuring a smooth wrapping process.

- Users can choose from different packing materials to suit specific wrapping needs.

- The design and production of the machine are in compliance with the 2006/42/EC directive, ensuring high standards of quality and safety.