Introduction

The DUAT Automatic Strapping Machine is revolutionizing the way we package and secure goods for transportation. With its advanced features and efficient design, this machine offers a seamless and hassle-free strapping experience. In this article, we will explore two key aspects of the DUAT Automatic Strapping Machine – strap tension control and troubleshooting guides – to help users understand its capabilities and overcome any potential challenges.

Strap Tension Control

One of the standout features of the DUAT Automatic Strapping Machine is its precise strap tension control. This ensures that your packages are securely strapped without causing any damage to the products. With adjustable tension settings, users can customize the strapping process according to their specific needs.

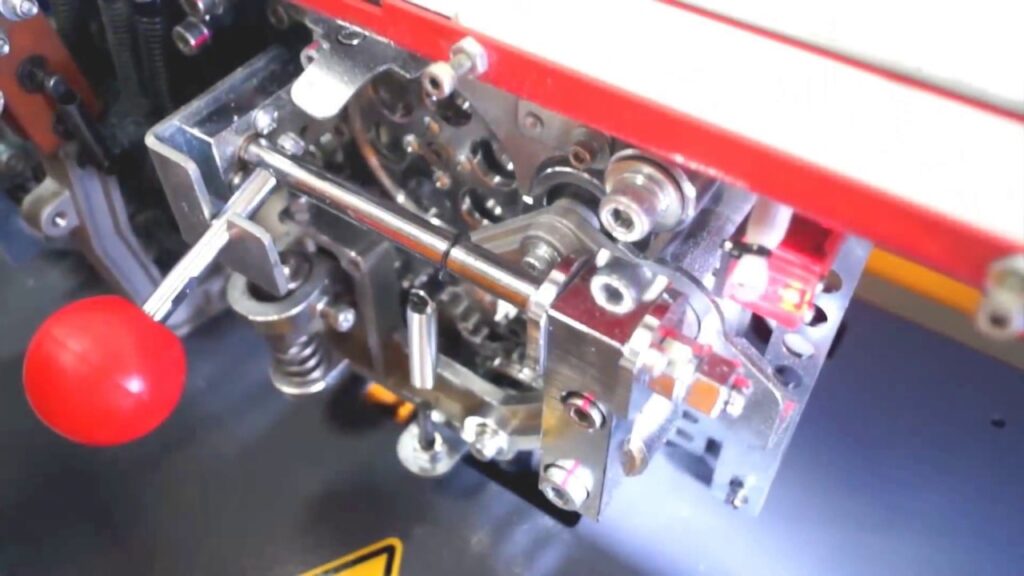

The DUAT Automatic Strapping Machine utilizes cutting-edge technology to achieve optimal strap tension. By using a combination of sensors and control mechanisms, the machine ensures that the tension is evenly distributed across the entire strap. This helps to prevent excessive strain on any one area, reducing the risk of damage to the packaged goods.

Additionally, the DUAT Automatic Strapping Machine offers real-time feedback on strap tension levels. This allows users to monitor and adjust the tension during the strapping process, ensuring that the desired level of tightness is achieved. Whether you are strapping delicate items or heavy-duty packages, this feature provides the flexibility and control required for a successful packaging operation.

Troubleshooting Guides

Despite its advanced features, it is possible to encounter a few challenges while using the DUAT Automatic Strapping Machine. However, the machine comes equipped with comprehensive troubleshooting guides to help users overcome these issues quickly and efficiently.

Excess Strap

One common problem that users may encounter is excess strap after the strapping process. This can be caused by various factors such as incorrect tension settings or improper loading of the machine. To resolve this issue, the DUAT Automatic Strapping Machine offers a step-by-step guide:

1. Check the tension settings: Ensure that the tension settings are adjusted correctly according to the package size and weight. Adjusting the tension settings can help eliminate excess strap.

2. Reload the machine: If the excess strap persists, unload the machine and reload it with the package positioned properly. Make sure that the strap is securely fed through the machine to avoid any tangling or overlapping.

3. Retension the strap: If the excess strap still persists, retension the strap manually after the initial strapping process. This can be done by adjusting the tension control mechanism according to the machine’s instructions.

Strap Stuck or Jammed

Another issue that users may face is a strap getting stuck or jammed during the strapping process. This can be caused by various factors such as improper feeding of the strap or a mechanical malfunction. The DUAT Automatic Strapping Machine provides a troubleshooting guide to address this problem effectively:

1. Check the strap path: Ensure that the strap is threaded properly through the feed mechanism and positioned correctly. Improper pathing of the strap can lead to jams or entanglement.

2. Clear any obstructions: If the strap is stuck or jammed, carefully remove any obstructions that may be blocking the strap’s path. This could include debris or excess packaging material.

3. Reset the machine: If the strap continues to be stuck or jammed, reset the machine by following the manufacturer’s instructions. In some cases, a simple reset can resolve the issue and allow for smooth strapping.

Conclusion

The DUAT Automatic Strapping Machine is a game-changer in the packaging industry with its advanced features and efficient design. Strap tension control ensures that packages are securely strapped without causing damage, while troubleshooting guides help users overcome any potential challenges.

With the DUAT Automatic Strapping Machine, users can experience seamless and hassle-free strapping, saving time and effort in their packaging operations. This innovative machine combines cutting-edge technology with user-friendly features to provide an unparalleled strapping experience.

Whether you are a small business owner or a large-scale manufacturer, the DUAT Automatic Strapping Machine offers the reliability and functionality required for your packaging needs. Invest in this advanced machine today and streamline your packaging process like never before.

Strapping Machines

“Effortless Strapping Made Simple: Discover the Key Features of Automatic Strapping Machines”