Robotic Engineered Solutions: Revolutionizing Industrial Automation

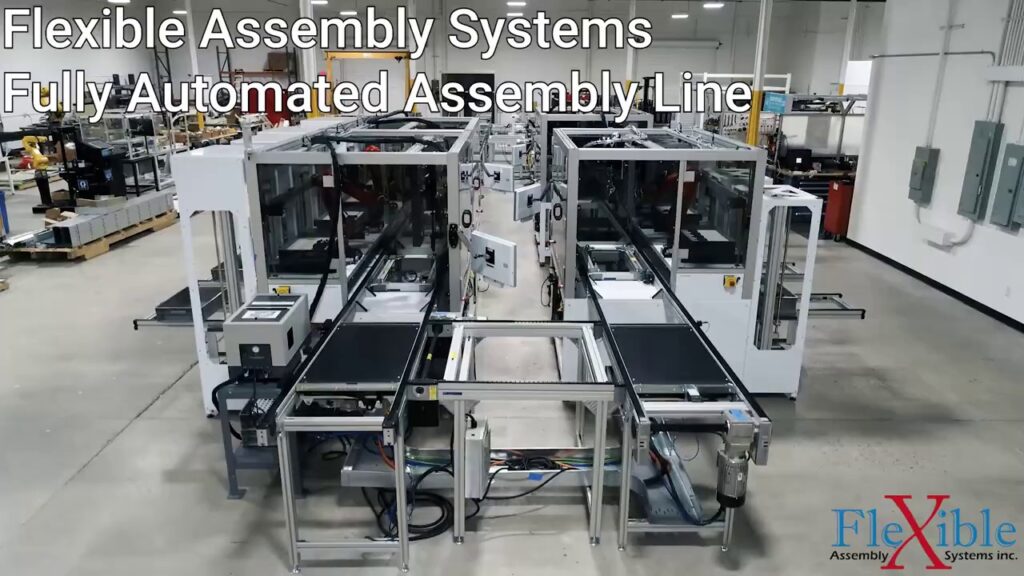

The world of manufacturing and production has undergone a tremendous transformation over the years, thanks to advancements in technology and the rise of industrial automation robots. Among the pioneers in this field is Flexible Assembly Systems, a company that has brought about a paradigm shift in the way industries operate and produce goods. Their state-of-the-art fully automated assembly line, equipped with multiple robotic solutions, has emerged as a game-changer, revolutionizing the industrial sector.

The benefits of industrial automation robots cannot be overstated. They offer enhanced efficiency, precision, and productivity, while reducing the margin of error and minimizing costs. The automated assembly line at Flexible Assembly Systems leverages these advantages and takes manufacturing to a whole new level.

One aspect that sets this fully automated assembly line apart is its scale. By utilizing an expansive layout, it is capable of handling large-scale production effortlessly. The sheer magnitude of the operation is awe-inspiring, as robots seamlessly work in unison, performing a plethora of tasks with unmatched speed and precision.

The key to the success of this automated assembly line lies in the integration of multiple robotic solutions. Each robot is precisely programmed and equipped with specialized tools to carry out specific tasks with utmost efficiency. Whether it's component assembly, product packaging, or quality control, these robotic solutions perform with unmatched accuracy, ensuring that every step of the production process is flawlessly executed.

To delve deeper into the capabilities of this automated assembly line, let's consider a case study. Company X was facing significant challenges in meeting their production targets due to manual labor limitations. They turned to Flexible Assembly Systems for a solution, and the results were astounding. The implementation of the fully automated assembly line not only led to a significant increase in production output but also surpassed the highest quality standards set by the industry.

The progressive structure of the assembly line ensures a seamless workflow, with each robot assigned a specific task in a sequential manner. From material handling to precise soldering or welding, every step is meticulously planned and executed. The synchronized movements of the robotic workforce create a symphony of efficiency, ultimately culminating in a finished product that meets the highest quality benchmarks.

Industrial automation robots have come a long way since their inception. The advent of advanced sensors, artificial intelligence, and machine learning has given rise to a new breed of robots that can adapt to changing environments and learn from their experiences. The fully automated assembly line at Flexible Assembly Systems incorporates these cutting-edge technologies, allowing for even greater flexibility and adaptability.

The predictive/foresight style of thinking comes into play when envisioning the future of robotics in the industrial sector. With the constant evolution and advancement of technology, the possibilities are virtually limitless. As machine learning algorithms continue to improve, robots will become more intelligent and self-reliant. We can expect to see them taking on increasingly complex tasks, operating with minimal human intervention, and ultimately redefining the boundaries of automation.

In conclusion, Flexible Assembly Systems, with its fully automated assembly line and industrial automation robots, has set a new standard for manufacturing excellence. By leveraging the power of robotics, they have achieved unparalleled efficiency, productivity, and precision. The integration of multiple robotic solutions, the narrative structure of the assembly line, and the ever-evolving technology in this field have propelled the industrial sector into a new era of automation. As we look towards the future, it is clear that this revolution is only the beginning, and the potential for further advancements is immense. Industrial automation robots are undoubtedly here to stay, and their impact will continue to reshape the landscape of industries worldwide.

Industrial Robot

"Streamlining Production: Harnessing the Power of Flexible Assembly Systems and Industrial Automation Robots for Fully Automated Assembly Lines"