Industrial Robots in Manufacturing: An Overview of PowerMILL Robot

In today’s rapidly advancing technological landscape, industrial robots have emerged as a game-changer in the field of manufacturing. These versatile machines offer numerous benefits, such as increased productivity, improved precision, and reduced human labor. As the demand for automation continues to rise, companies are constantly striving to develop more efficient and innovative robotic programming solutions. Delcam UK, a leading software developer, has introduced PowerMILL Robot, a dedicated programming solution that is set to revolutionize the industrial robotics industry.

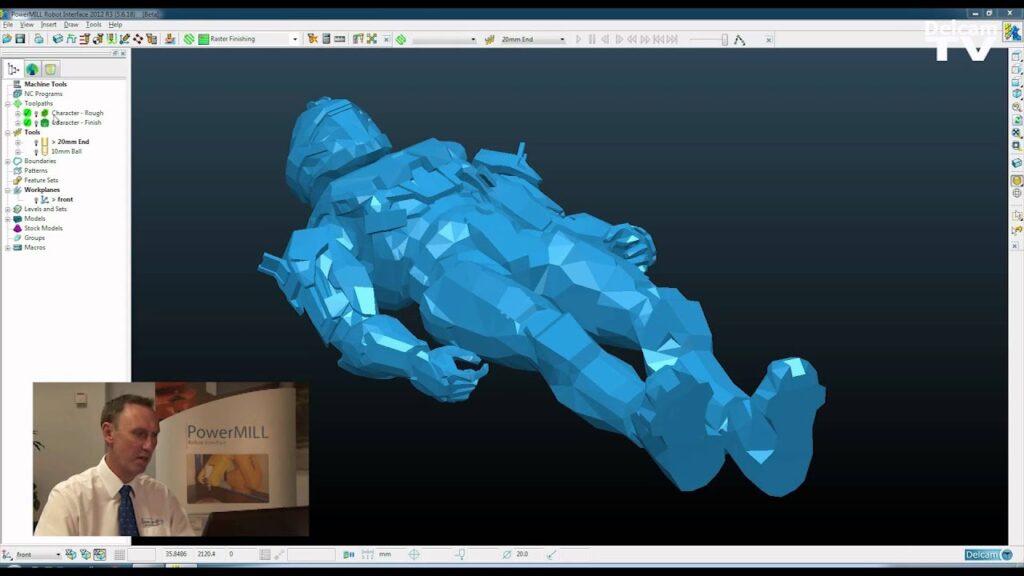

PowerMILL Robot, presented by Robin Smith from Delcam UK, is specifically designed to streamline the programming process for industrial robots. This advanced software enables users to generate accurate and reliable robot programs with ease. The video provides an insightful overview of the capabilities and features of PowerMILL Robot, shedding light on the potential it holds for transforming the manufacturing sector.

The use of industrial robots in manufacturing has become increasingly prevalent, primarily due to their ability to perform repetitive tasks with precision and efficiency. These robots are equipped with advanced sensors and actuators that allow them to adapt to different production environments and carry out complex operations. However, programming these robots has often been a time-consuming and intricate process that requires specialized knowledge and expertise.

PowerMILL Robot addresses this challenge by offering a user-friendly interface that simplifies the programming workflow. The software utilizes a graphical programming approach, allowing users to create robot programs through a visual representation of the desired robot movements. This intuitive interface eliminates the need for manual coding, making it accessible to both experienced engineers and novices in the field.

One of the key features of PowerMILL Robot is its collision avoidance system. Industrial robots operate in close proximity to machinery and other objects, making collision prevention a critical concern. This software utilizes advanced algorithms to detect potential collisions and automatically adjusts the robot’s path to avoid accidents. This not only ensures the safety of the workspace but also minimizes costly damages to equipment and materials.

Moreover, PowerMILL Robot incorporates advanced simulation capabilities that enable users to visualize the robot’s movements before implementation. This virtual environment allows for the identification and rectification of any potential issues or bottlenecks in the programming stage itself, saving valuable time and resources. With the power to simulate and optimize robot programs, manufacturers can significantly improve production efficiency and reduce downtime.

The versatility of PowerMILL Robot is highlighted by its compatibility with a wide range of industrial robots and applications. Whether it’s welding, milling, material handling, or painting, this software provides comprehensive programming solutions tailored to specific manufacturing requirements. Its extensive library of post-processors ensures seamless integration with various robot brands, making it a versatile choice for manufacturers across different industries.

As the manufacturing landscape rapidly evolves, the integration of industrial robots into production processes is becoming increasingly vital for businesses to thrive. The introduction of dedicated programming solutions like PowerMILL Robot marks a significant milestone in the advancement of industrial robotics. With its user-friendly interface, advanced collision avoidance capabilities, and comprehensive simulation features, PowerMILL Robot offers an efficient and reliable solution for programming industrial robots.

In conclusion, the video presentation by Robin Smith from Delcam UK sheds light on the innovative programming solution, PowerMILL Robot. With its user-friendly interface and advanced features, this software is poised to revolutionize the way industrial robots are programmed and utilized in the manufacturing sector. As the demand for automation continues to rise, the integration of industrial robots into production processes will undoubtedly become a defining factor for success. Delcam UK’s PowerMILL Robot is poised to play a pivotal role in shaping the future of manufacturing automation, offering businesses enhanced productivity, precision, and overall efficiency.

Industrial Robot

“Mastering Programming Industrial Robots: Unleashing the Power of PowerMILL and Transforming Manufacturing Processes”