The MotoMini: Revolutionizing Industrial Robots Applications

In the ever-evolving world of technology, industrial robots have become one of the most important tools in the manufacturing industry. They have significantly improved efficiency, productivity, and safety in various sectors. The rise of automation has opened doors for countless possibilities, where robots can perform intricate tasks with precision and speed. One such remarkable innovation is the MotoMini, a 6-axis small industrial robot presented at Pack Expo Connects 2020.

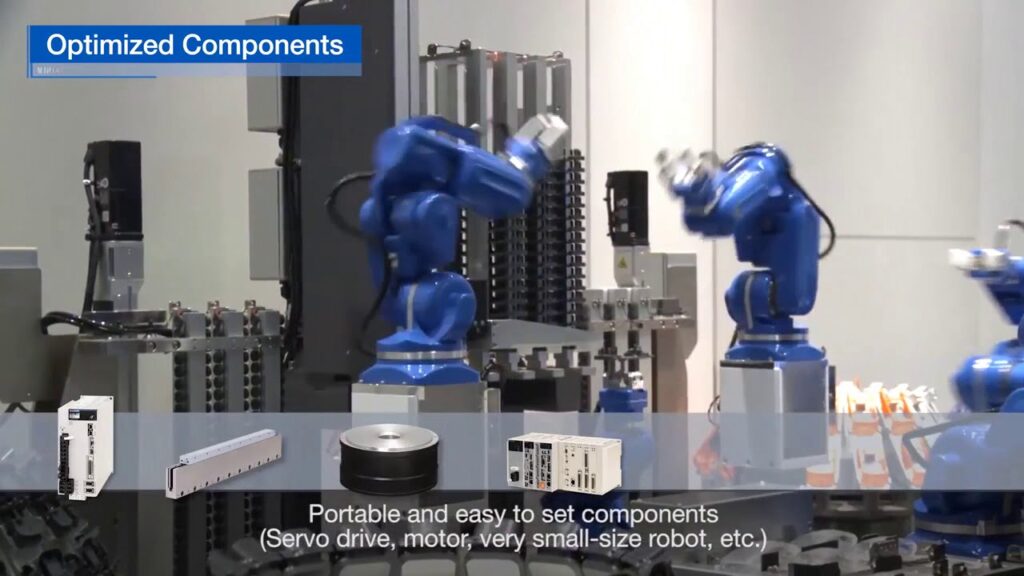

With its compact design and exceptional performance capabilities, the MotoMini has gained popularity for its applications in high-speed picking, handling, and assembly processes. This article serves as an overview of the MotoMini robot and its extensive applications in the realm of industrial robotics.

Industrial robots have been a game-changer for many businesses, and the MotoMini takes this revolution to new heights. Developed by innovative minds, it combines advanced technology and cutting-edge engineering to deliver superior performance. Its six-axis design allows for excellent flexibility and dexterity, enabling it to navigate tight spaces and handle intricate tasks with ease.

One of the standout features of the MotoMini is its high-speed capabilities. With rapid acceleration and deceleration, this robot can complete tasks in a fraction of the time it would take a human worker. This means increased productivity and efficiency in manufacturing processes, leading to significant cost savings for businesses.

The MotoMini’s applications in the industrial sector are vast and varied. Its primary function lies in picking and placing items in a highly efficient manner. With its precision and speed, it can handle delicate objects that require gentle handling, while also being robust enough to lift heavier items. This versatility makes it ideal for a wide range of industries, including electronics, automotive, healthcare, and food and beverage.

In the electronics industry, the MotoMini plays a crucial role in assembling intricate components. With its precise movements and delicate touch, it can handle small circuit boards and soldering tasks with unmatched precision. This not only improves the quality of the final product but also reduces the margin for error, contributing to cost savings and customer satisfaction.

The automotive industry has also seen the transformative power of the MotoMini. In assembly lines, this small industrial robot can perform complex tasks such as screwing, riveting, and welding with incredible accuracy. Its ability to repeat these tasks consistently ensures uniformity and reliability in the final product.

In healthcare, the MotoMini’s applications are far-reaching. It can be utilized in pharmaceutical manufacturing, handling and packaging delicate medications with minimal human intervention. Its sterile design and precise movements ensure the highest standards of cleanliness and safety.

The food and beverage industry, too, has embraced the MotoMini for its efficiency and hygienic features. It can handle sensitive food products with care, ensuring minimal damage and contamination. This is especially crucial in the packaging process, where maintaining product integrity is of utmost importance.

The MotoMini’s versatility is not limited to these industries alone. Its applications extend to logistics and warehousing, where it can efficiently stack and arrange goods on pallets. It can also be integrated into collaborative robotic systems, working alongside human workers to enhance productivity and safety.

As we dive deeper into the world of automation, the MotoMini is just the beginning of what’s to come. With advancements in artificial intelligence and machine learning, we can expect industrial robots to become even more intelligent and adaptable. The MotoMini exemplifies the potential of these advancements and how they can revolutionize various industrial processes.

In conclusion, the MotoMini is a groundbreaking 6-axis small industrial robot that has found its place in a wide range of industries. From high-speed picking and handling to intricate assembly tasks, it has proven to be a game-changer in terms of efficiency, productivity, and safety. Its small size and advanced capabilities make it a versatile tool for countless applications. As we look ahead, it is evident that the MotoMini is just the tip of the iceberg when it comes to the future of industrial robotics.

Industrial Robot

“Unveiling the Versatile Applications of MotoMini and Industrial Robots: A Comprehensive Overview”