Heat Shrinking Machine Revolutionizes Cable Processing

Heat shrink tubing has long been a popular method of protecting and insulating electrical cables. Its ability to shrink down when heated, conforming to the cable's shape and providing a tight seal, has made it a staple in the industry. However, the traditional method of heat shrinking tubes has always required the cable to be rotated manually to ensure an even distribution of heat. This process is time-consuming, labor-intensive, and not always accurate.

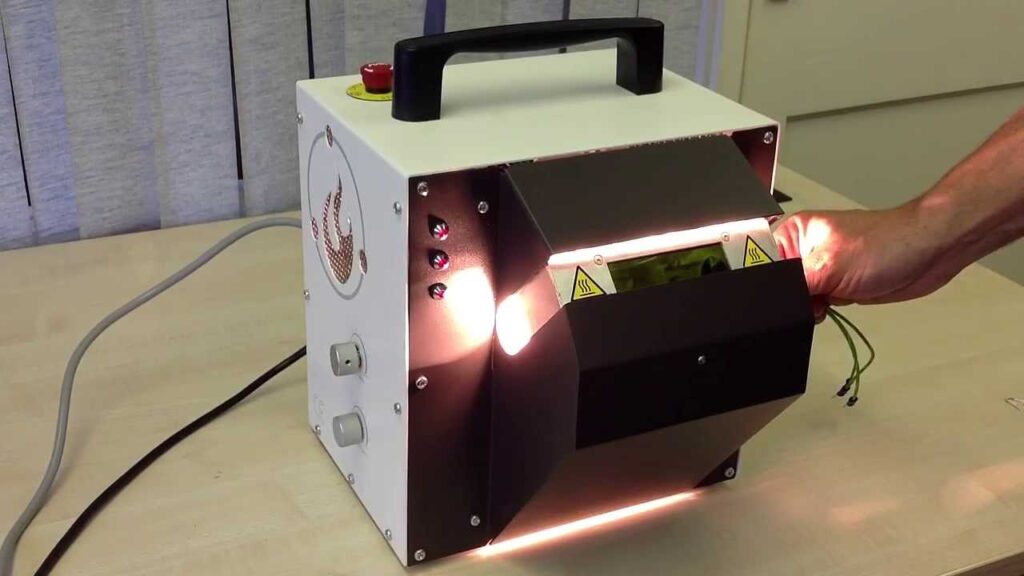

But now, a revolutionary innovation in heat shrink tube processing has emerged - the Haloblaze Heat Shrink Tube Processing Machine. This cutting-edge machine is set to transform the way we process cables, making it faster, more efficient, and more precise than ever before.

The Haloblaze Heat Shrink Tube Processing Machine boasts a 360-degree shrink capability without the need for manually rotating the cable. This unprecedented feature eliminates the need for human intervention during the shrinking process, allowing for seamless and continuous processing. This not only saves time and labor costs, but it also ensures a consistently high-quality result.

Furthermore, the machine offers full quality control, thanks to its advanced temperature control system. This system monitors and regulates the heat distribution during the shrinking process, preventing any burning or overheating of the cable. This level of precision and control guarantees that each cable processed through the machine is of the highest standard, minimizing the risk of faulty or damaged products.

The Haloblaze Heat Shrink Tube Processing Machine is a game-changer for the industry, offering an array of benefits that were previously unimaginable. With its ability to process cables without the need for manual rotation, it significantly reduces processing time, allowing for higher production rates. This equates to increased efficiency and productivity, making it a valuable asset for any manufacturing facility.

Moreover, the machine's full quality control feature ensures that the end product is free from defects and meets the highest standards of quality. This not only improves customer satisfaction but also reduces the likelihood of costly recalls or repairs.

In addition to its practical advantages, the Haloblaze Heat Shrink Tube Processing Machine also brings with it a host of environmental benefits. By eliminating the need for manual rotation and reducing processing time, it minimizes energy consumption and carbon emissions. This commitment to sustainability is increasingly important in today's society, where industries are under pressure to reduce their ecological footprint.

The introduction of the Haloblaze Heat Shrink Tube Processing Machine has been met with great enthusiasm within the industry. Customers who have already implemented this innovation in their processes have reported significant improvements in production efficiency and product quality.

One such customer, a leading manufacturer of electrical cables, shared their experience with the Haloblaze machine. They found that the 360-degree shrink capability not only sped up their production process but also eliminated the risk of human error. The full quality control system gave them peace of mind, knowing that every cable processed was up to their stringent standards.

The company behind the Haloblaze Heat Shrink Tube Processing Machine has also received accolades for their groundbreaking innovation. They have been recognized for their commitment to advancing the industry and providing solutions that address the pain points of cable manufacturers.

In conclusion, the Haloblaze Heat Shrink Tube Processing Machine is a groundbreaking innovation that revolutionizes the way we process cables. Its 360-degree shrink capability, full quality control system, and energy-efficient operation make it an invaluable asset for any cable manufacturing facility. By eliminating the need for manual rotation and ensuring consistent and precise processing, it saves time, reduces costs, and improves overall product quality. With the introduction of this game-changing machine, the future of heat shrink tube processing looks brighter than ever.

Shrinking Machine

"Efficient Heat Shrink Tube Processing and Shrink Machines: Boost Your Workflow with Advanced Technology"