Automated Packaging Systems Revolutionize the Fulfillment Center Industry

In the ever-evolving world of e-commerce, efficiency and speed are of paramount importance in fulfillment centers. This is where automated packaging systems come into play, transforming the way businesses handle their end-of-line packaging operations. Companies like Ranpak have been at the forefront of packaging automation solutions, providing cutting-edge technologies that optimize the packing line process and ensure a seamless customer experience.

Fulfillment centers have witnessed a drastic change in recent years, as the demand for online shopping continues to soar. The traditional manual packing methods are no longer sufficient to meet the growing demands of today’s fast-paced industry. This is where the benefits of automated packaging systems truly shine.

The use of automated packaging systems not only enhances efficiency but also reduces the risk of error. These systems are designed to handle the packaging process seamlessly, significantly reducing the time taken to pack each order. With automated solutions, businesses can process a higher volume of orders in a shorter period, leading to increased productivity and customer satisfaction.

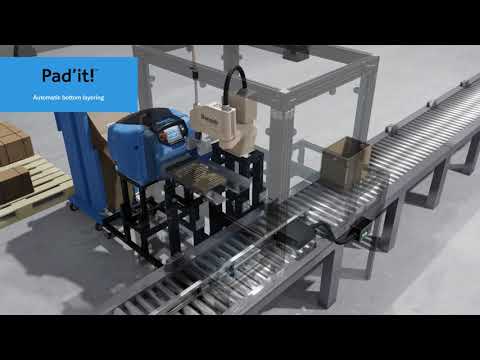

Ranpak’s Automated End-Of-Line Packaging Operation is a prime example of how innovation is transforming the packaging process. This state-of-the-art system utilizes advanced robotics and artificial intelligence to streamline the packaging line. By integrating this technology into their fulfillment centers, businesses can expect a significant improvement in efficiency and overall performance.

One of the key advantages of Ranpak’s Automated Packaging Systems is their versatility. These systems are capable of handling various types of packaging, from boxes to bubble wrap, ensuring that each product is securely protected during transit. The flexibility of these systems allows businesses to cater to a wide range of products, adapting to the diverse needs of their customers.

Another notable feature of Ranpak’s Automated Packaging Systems is their ability to reduce waste. These systems use an efficient packaging material called paper cushioning. This sustainable alternative to plastic ensures that each package is protected while also being environmentally friendly. By adopting this eco-conscious approach, businesses can contribute to the global effort of reducing plastic waste and creating a greener future.

The implementation of automated packaging systems also has significant cost-saving implications for businesses. With increased efficiency and reduced labor requirements, companies can optimize their resources and allocate them to other areas of their operations. This not only improves overall profitability but also allows businesses to invest in technologies that further enhance their productivity.

The future of fulfillment centers undoubtedly lies in automation. As technology continues to advance, we can expect even more innovative solutions to enhance the packaging process. From autonomous robots that pick and pack orders to sophisticated tracking systems that provide real-time updates, the possibilities are endless.

The impact of automated packaging systems goes beyond the fulfillment center industry. These technologies also benefit customers, ensuring that their orders are processed and delivered efficiently. With shorter delivery times and improved order accuracy, businesses can build trust and loyalty among their customer base, ultimately leading to sustainable growth and success.

In conclusion, the rise of e-commerce has brought with it the demand for faster, more efficient packaging processes. Automated packaging systems, like the ones provided by Ranpak, have emerged as the solution to this challenge. Through their advanced technologies, these systems optimize the fulfillment center operations, reduce waste, and improve overall productivity. As businesses continue to recognize the benefits of automation, we can expect a revolution in the packaging industry, shaping the way orders are processed and delivered.

Automatic Packing Line

“Streamlining Packaging Operations: Automating End-Of-Line Packaging and Packaging Systems”