**Types of Industrial Robots: Redefining Automation in the Manufacturing Industry**

In today’s fast-paced, technologically advanced world, the manufacturing industry is constantly seeking innovative solutions to streamline operations and enhance productivity. One remarkable development in this field is the advent of industrial robots. These highly efficient machines not only enhance productivity and accuracy but also allow for the automation of repetitive and labor-intensive tasks. In this article, we will delve into the various types of industrial robots and explore how they have revolutionized the manufacturing industry.

*Before we begin our exploration, let us take a moment to marvel at the sheer capabilities of industrial robots. With payloads ranging from 200 to 1000 Kg, these robots can seamlessly handle different tasks, making them an ideal choice for a wide variety of applications. Additionally, by integrating with over 10 different kinds of top operational modules, these robots can easily adapt to different environments and functionalities.*

**Robotic Arms: The Backbone of Industrial Automation**

One of the most common types of industrial robots is the robotic arm. These versatile machines are designed to perform a wide range of tasks with exceptional precision and speed. Equipped with various sensors, hydraulic systems, and articulated arms, robotic arms can mimic human movements, allowing them to perform complex tasks such as welding, painting, and assembly. These robots are instrumental in reducing human error, increasing efficiency, and ensuring a seamless production process.

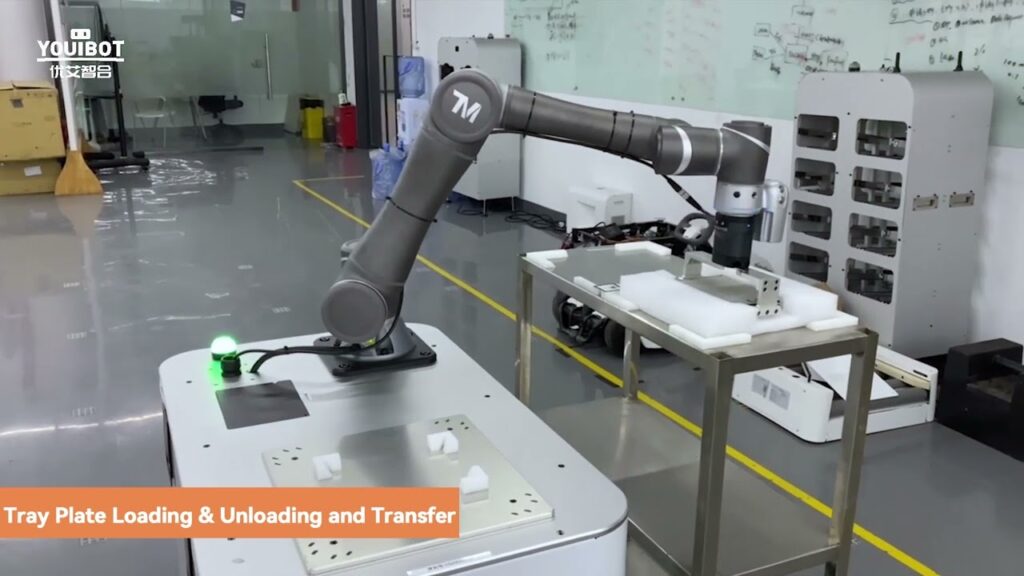

**AGVs and Mobile Robots: Navigating the Future**

Another type of industrial robot that is gaining significant traction in recent years is Automated Guided Vehicles (AGVs) and mobile robots. These intelligent machines are revolutionizing the way materials are transported within manufacturing facilities. AGVs and mobile robots utilize advanced navigation systems such as lasers, cameras, and magnetic guidance to transport goods from one place to another in a highly efficient and automated manner. With their ability to navigate dynamically changing environments, these robots enhance productivity while minimizing the risk of accidents and human injuries.

**Collaborative Robots (Cobots): Merging Man and Machine**

Collaborative robots, also known as cobots, mark a significant departure from traditional industrial robots. These robots are specifically designed to work alongside human operators, sharing space and tasks harmoniously. Cobots are equipped with sophisticated sensors that detect human presence, allowing them to adjust their speed and force accordingly to ensure human safety. With their ability to perform tasks that require delicate handling or high precision, cobots have found application in industries such as electronics, pharmaceuticals, and automotive assembly lines.

**Delta Robots: Precision and Speed Unleashed**

Delta robots are beloved for their remarkable precision and incredible speed. These robots feature a unique design, with three arms connected to a central pillar. This arrangement allows delta robots to perform tasks that require lightning-fast movements, such as pick and place operations in the food and packaging industries. With their unparalleled speed and precision, delta robots significantly enhance production efficiency and output.

**Cartesian Robots: Simplifying Linear Movements**

Cartesian robots, also known as gantry or rectilinear robots, are widely employed for tasks that involve linear movements on a fixed plane. They are especially popular in industries such as machining, welding, and material handling. Cartesian robots utilize three sliding joints, allowing for precise and controlled movements along three axes. With their ability to perform repetitive tasks with consistent accuracy, these robots are instrumental in reducing operational costs and cycle times.

**Articulated Robots: Versatility Redefined**

Articulated robots are characterized by their jointed arm structure, which closely resembles that of a human arm. This design allows articulated robots to mimic human movements and perform tasks with exceptional dexterity and versatility. Whether it’s welding, material handling, or painting, these robots excel in a variety of tasks across industries. Additionally, with their wide range of motion, articulated robots can easily navigate complex environments and adapt to changing production requirements.

**Conclusion**

As we conclude our journey into the world of industrial robots, it is evident that these intelligent machines have redefined automation in the manufacturing industry. With their exceptional precision, speed, and versatility, industrial robots have become indispensable assets for enhancing productivity and maximizing operational efficiency. The various types of industrial robots, such as robotic arms, AGVs and mobile robots, collaborative robots, delta robots, Cartesian robots, and articulated robots, each bring their unique capabilities and functionalities, enabling manufacturers to meet the ever-increasing demands of the modern world. As we move forward into the future of manufacturing, industrial robots will undoubtedly continue to shape and revolutionize this dynamic industry.

Industrial Robot

“Exploring the Construction of Intelligent Bases for a Variety of Robots: A Look into Different Types of Industrial Robotics”