Semi-Automatic Strapping Machine: The Reliable Solution for Efficient Packaging

The world of packaging has come a long way, with technology continuously advancing to streamline and enhance the packaging process. One such innovation that has gained significant popularity in recent years is the semi-automatic strapping machine. This article aims to provide an in-depth analysis of the functionality and benefits of this efficient packaging solution.

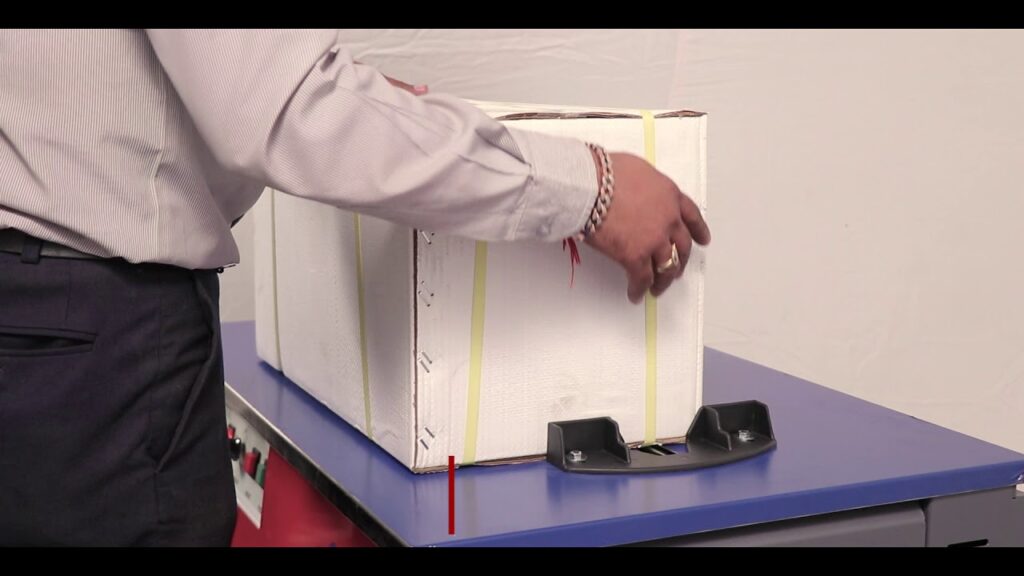

The semi-automatic strapping machine is revolutionizing the way goods are packaged, offering a reliable and time-saving alternative to manual strapping. With its automated features, this state-of-the-art machine ensures a secure and sturdy strapping for a wide range of products, from small packages to heavy cartons.

The fundamental principle behind the semi-automatic strapping machine is its ability to automate the strapping process, eliminating the need for manual effort while maintaining the integrity of the package. This machine employs the use of a durable polypropylene strap that is guided through the device. The strapping is then tensioned and sealed with a heat-sealing mechanism, ensuring a tight and secure grip around the package.

One of the notable advantages of the semi-automatic strapping machine is its ease of use. The user-friendly interface allows operators of all skill levels to operate the machine efficiently. With just a few simple steps, the entire strapping process can be completed swiftly, saving valuable time and energy.

Furthermore, the semi-automatic strapping machine offers exceptional versatility, accommodating various package sizes and shapes. This adaptability is crucial, as it allows businesses to streamline their packaging process without compromising on the quality and safety of their products.

Additionally, the semi-automatic strapping machine ensures consistent and reliable performance, minimizing the risk of human errors during the packaging process. With its precision-engineered design, this machine guarantees uniform tensioning and sealing of the strap, providing a professional and aesthetically pleasing result.

Business owners and packaging professionals can significantly benefit from integrating the semi-automatic strapping machine into their operations. Firstly, it improves productivity by reducing packaging time, allowing employees to focus on other essential tasks. The machine's high strapping speed ensures that packaging targets are met promptly and efficiently.

Secondly, the semi-automatic strapping machine offers substantial cost savings in the long run. By eliminating the need for manual labor, businesses can allocate their resources to more critical areas of their operations. Additionally, the machine's reliable performance reduces the occurrence of damaged packages during transportation, minimizing costly product returns and replacements.

Furthermore, the semi-automatic strapping machine prioritizes worker safety. By automating the strapping process, it reduces the risk of employee injuries, such as strains and sprains associated with manual strapping. This creates a safer working environment and enhances overall employee satisfaction.

In conclusion, the semi-automatic strapping machine stands as a game-changer in the packaging industry. Its automated features, ease of use, versatility, and reliability make it an invaluable asset for businesses of all sizes. With this innovative packaging solution, companies can improve productivity, reduce costs, and ensure the safe and secure transport of their products. Embracing the semi-automatic strapping machine is a step towards efficiency and effectiveness in the ever-evolving world of packaging.

Strapping Machines

"Semi-Automatic Strapping Machine: Streamlining Packaging Procedures for Efficiency and Precision"