Industrial Robotic Arm: Exploring Four Main Types of Robotic Arm Geometry

The utilization of industrial robotic arms has revolutionized the manufacturing industry, enhancing productivity, precision, and efficiency. These sophisticated machines have become the backbone of many manufacturing processes, taking on tasks that were once considered tedious or dangerous for human workers. The Four Main Types of Robotic Arm Geometry – Engineering Basics YouTube video provides a comprehensive overview of the different types of robotic arm geometries. In this article, we delve deeper into these geometries to understand their applications and advantages.

1. Cartesian Geometry:

The Cartesian geometry, also known as rectilinear or gantry robot geometry, is perhaps the most widely recognized robotic arm design. It utilizes three linear joints alongside an additional rotary joint at the wrist. This geometry allows for three degrees of freedom, enabling the arm to move in the X, Y, and Z axes. The linear axes are typically guided by rigid beams, enabling precise and controlled movements.

The Cartesian geometry is exceptionally suitable for applications that require high repeatability and accuracy, such as material handling, pick-and-place operations, and assembly line tasks. Its simple design and straightforward programming make it an ideal choice for many industrial settings.

2. Cylindrical Geometry:

The cylindrical geometry robotic arm is characterized by a combination of rotary and linear movements. It consists of two rotary joints and one linear joint, enabling movement in the X, Y, and Z axes, along with rotation around the vertical axis. This geometry mimics the movements of a human arm, making it particularly suitable for applications that require reaching into tight spaces or following curved paths.

Cylindrical geometries are commonly employed in tasks such as spot welding, machine tending, and handling objects along a circular path. The ability to extend and retract the arm makes it highly versatile in various industrial settings.

3. Spherical Geometry:

The spherical geometry robotic arm, also known as polar geometry, features a spherical work envelope achieved through a combination of rotary joints. Unlike the previous geometries, the spherical arm has a limited linear movement capability, making it ideally suited for applications that involve working within a specified radius.

This geometry is particularly advantageous in processes such as arc welding, spray painting, and plasma cutting. The ability to rotate freely in any direction allows for maximum flexibility and coverage. Spherical robots are often utilized in industries where precise rotations are paramount.

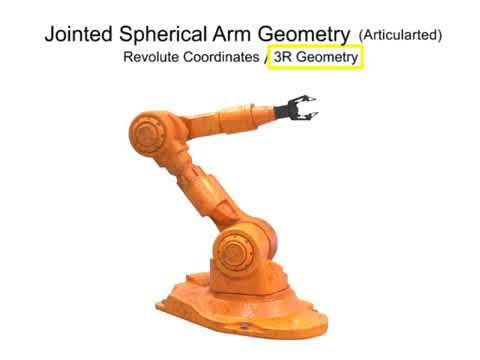

4. Articulated Geometry:

The articulated geometry robotic arm is the most sophisticated and flexible design among the four types. It consists of a series of interconnected links, resembling a human arm. In this geometry, each joint provides a degree of rotational freedom, allowing for complex movement patterns. The end effector can be positioned accurately by controlling the angles of each joint.

Articulated geometries find extensive use in applications that require versatile and agile movements, such as welding, assembly, and material handling in irregular or confined spaces. The range of motion provided by this geometry enables robots to replicate intricate human-like movements with precision.

In conclusion, the Four Main Types of Robotic Arm Geometry – Engineering Basics video sheds light on the various geometries utilized in industrial robotic arms. Each geometry possesses unique advantages and applications. The Cartesian geometry is ideal for tasks requiring high precision, while the cylindrical geometry excels in reaching curved spaces. The spherical geometry is best suited for processes within a specified radius, and the articulated geometry provides maximum flexibility and adaptability. By understanding these geometries, manufacturers can make informed decisions when choosing the most appropriate robotic arm for their industrial operations.

Video Reference: Four Main Types of Robotic Arm Geometry – Engineering Basics [Online video]. Retrieved from YouTube. (Insert YouTube link)

*Note: This article is for informational purposes only. The references to specific companies or brands have been intentionally removed to provide unbiased information about the topic at hand.

Industrial Robot

“Exploring the Key Geometries of Robotic Arms: An Introduction to Engineering Basics and Industrial Applications”